Impurity removal and purification system and method for white wine

A technology for liquor and liquor, applied in the field of liquor purification and treatment, can solve the problems of weak liquor taste, many storage equipment, increased energy consumption, etc., and achieve the effects of enhancing aroma and sweetness, improving volatilization speed, and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

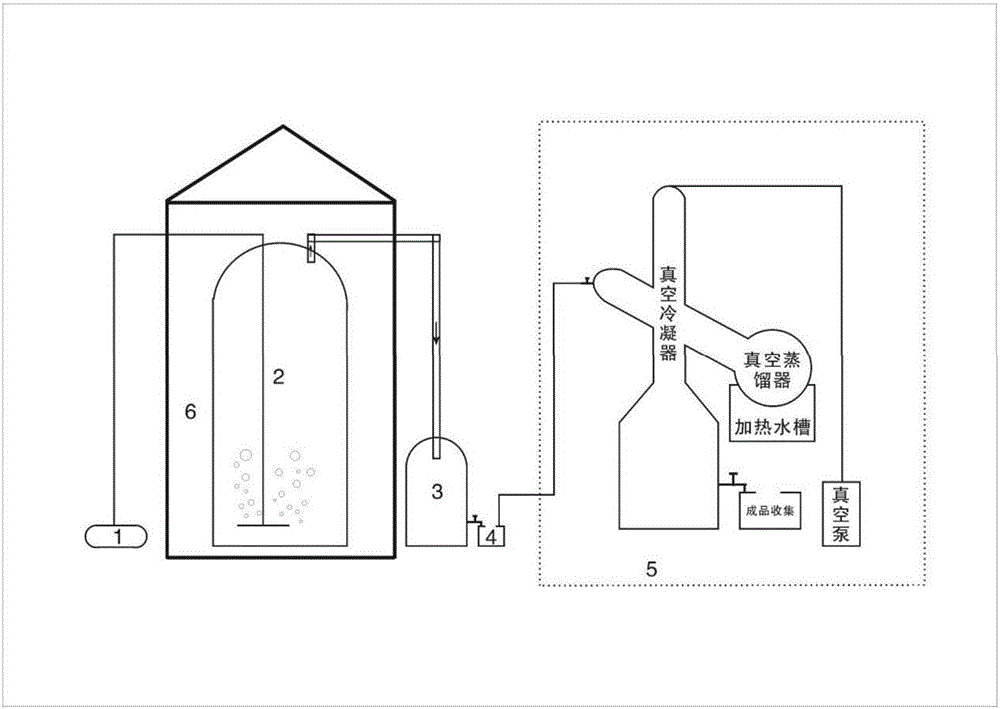

[0035] The present invention is described in further detail below with reference to accompanying drawing:

[0036] refer to figure 1 , The system of the present invention includes: an air pump 1, a wine storage tank 2, a condenser 3, a recovery tank 4, a vacuum distillation separation device 5 and a glass house 6. Among them, the condenser 3 is connected between the wine storage tank 2 and the recovery tank 4 through pipelines, and is used to condense the volatilized gas in the wine liquid into liquid and recycle it into the recovery tank 4; the vacuum distillation and separation equipment is connected with the recovery tank 4 through pipelines , used for the fine separation of secondary impurities on the liquid recovered in the recovery tank 4, so as to volatilize harmful substances and keep beneficial substances for collection and utilization.

[0037] The condenser 3 is a sealed container made of stainless steel. It consists of an upper cavity, a lower cavity and several c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com