High-density culture and pre-harvesting method of microalgae

A technology of high-density cultivation and harvesting method, which is applied in the field of high-density cultivation and pre-harvesting of microalgae, which can solve the problems of high density, low biomass of microalgae, and difficult harvesting of algae cells, and achieve the effect of reducing the cost of cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Membrane Photobioreactor

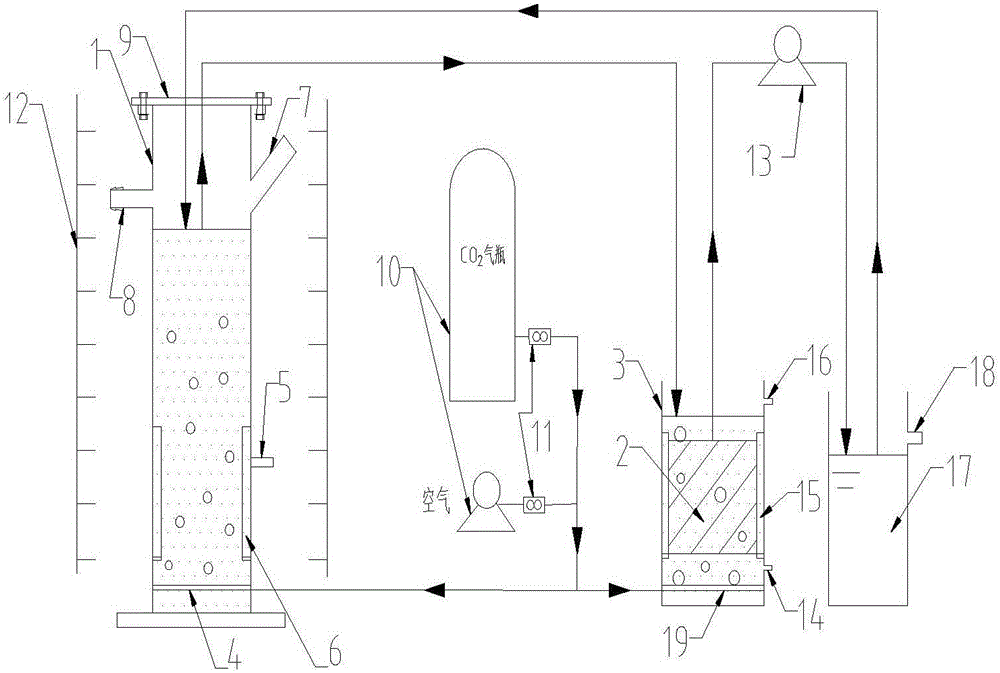

[0038] The membrane photobioreactor that the present invention adopts, as figure 1 As shown, it mainly includes a photobiological reaction device 1 , an illumination device 12 , a gas supply device 10 , a membrane permeation device 2 , and a permeate collection device 17 . The illumination device 12 is located outside the photobioreaction device 1, the top of the photobioreaction device 1 is provided with a first sample inlet 7 and an air outlet 8, and the bottom part is provided with a first sample outlet 5 and a first membrane assembly slot 6, The bottom is provided with a first microporous aeration tube 4 . The gas supply device 10 is connected to the first microporous aeration pipe 4 at the bottom of the photobioreaction device 1 and connected to the second microporous aeration pipe 19 at the bottom of the filter tank 3 through pipelines. The gas supply device 10 includes an air supply device and CO 2 supply unit, air supply uni...

Embodiment 2

[0040] Embodiment 2: the growth situation of Spirulina platensis in photobioreactor

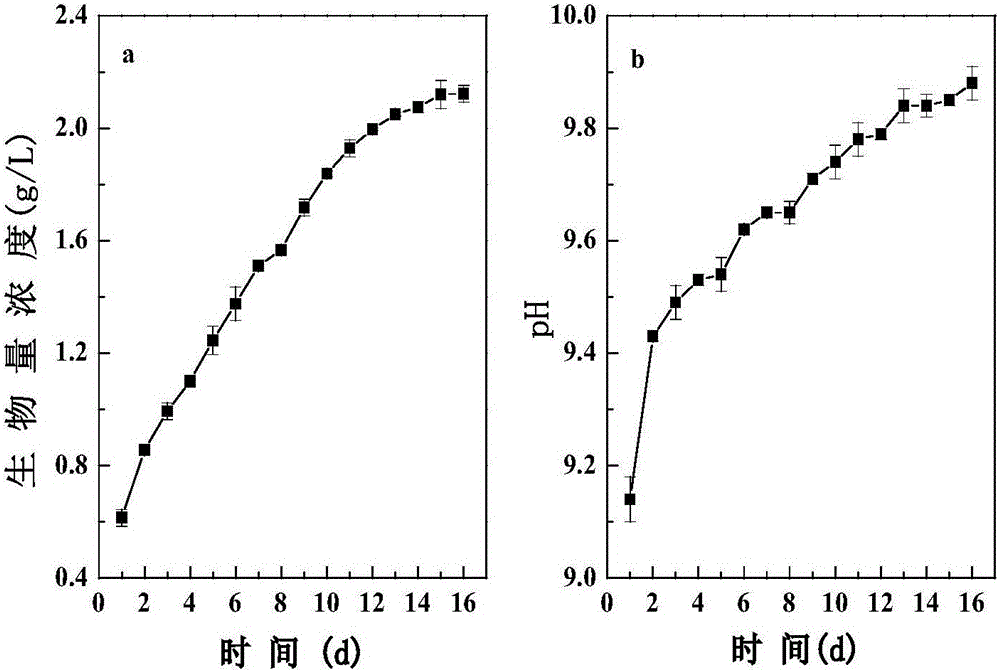

[0041] The Spirulina Spirulinaplatensis used in this example was purchased from the Freshwater Algae Species Bank of the Institute of Hydrobiology, Chinese Academy of Sciences, numbered FACHB-901. First investigate the growth of Spirulina platensis in the photobioreactor, the culture medium is improved Zarrouk medium, and its main components and configuration and usage methods are shown in Tables 1 and 2 (A 5 Add 1 mL per liter of culture medium). The incubator was set with a light of 3000Lux, a light-to-dark ratio of 16 / 8, and the temperature of the incubator was controlled at 30±1°C. As the culture time goes on, the density of algae gradually increases, and the spirulina grows rapidly from the 1st to the 10th day, and the biomass reaches 1.837g / L; after the 16th day of cultivation, the biomass is stable at about 2.122g / L, as figure 2 as shown in a. From figure 2 It can be seen in b th...

Embodiment 3

[0046] Example 3: Determination of Volume Concentration Factor in Membrane Photobioreactor

[0047] When the membrane module is used to filter and concentrate the algae liquid in MPBR, the volume concentration coefficient of the algae liquid (volume concentration coefficient f in -The volume of algae solution added to the filter tank, L; F in -The volume of remaining algae liquid in the filter tank, L) can increase the biomass concentration of algae products, but if the volume concentration factor is too high, it will aggravate membrane fouling, so it is necessary to choose an appropriate volume concentration factor.

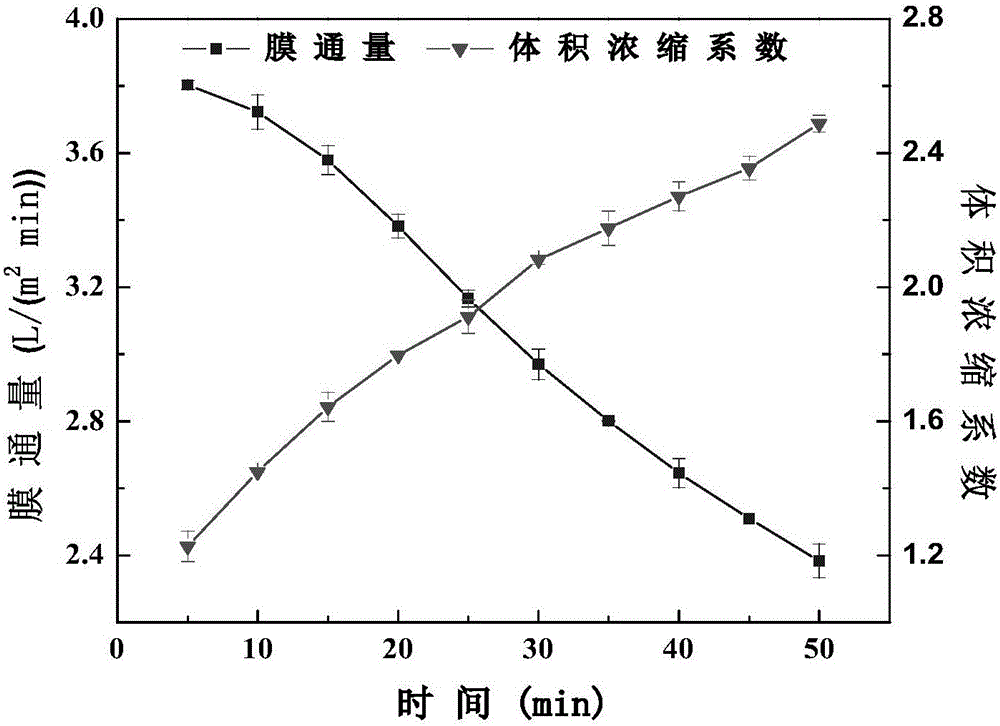

[0048] When the concentration of the algae liquid was 1.855g / L, the experiment was carried out in the filter tank, and the results were as follows: image 3 Shown: With the increase of the volume concentration coefficient, the concentration of the algae liquid increases, and the membrane flux gradually decreases; the volume concentration coefficient of the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com