Subunit-level sequence control logic module for nuclear power plant and application method of subunit-level sequence control logic module

A sequence control and logic module technology, applied in the direction of electrical program control, program control, comprehensive factory control, etc., can solve the problems of complex manual operation process, low level of automatic control, and prone to misoperation, so as to reduce operation intensity and reduce The effect of working intensity and avoiding misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] An application method of subgroup-level sequential control logic modules in nuclear power plants, the characteristics of the method are:

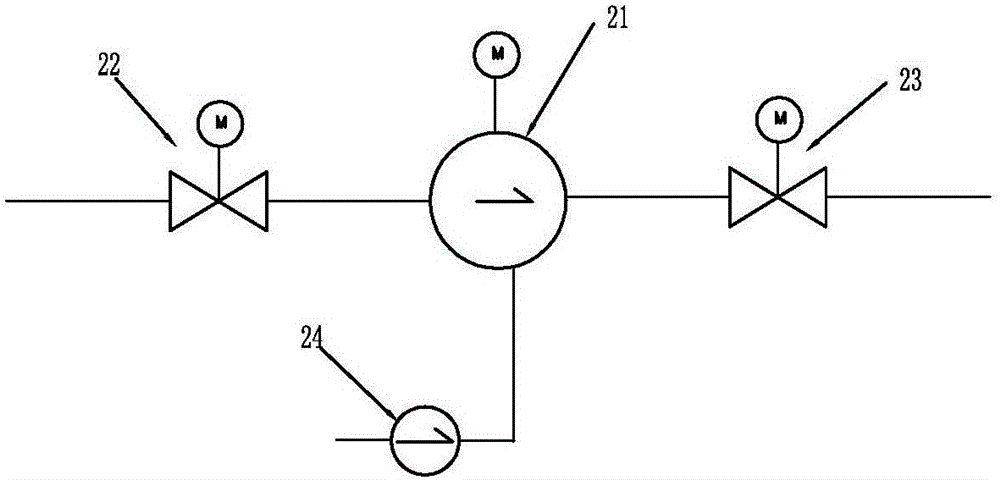

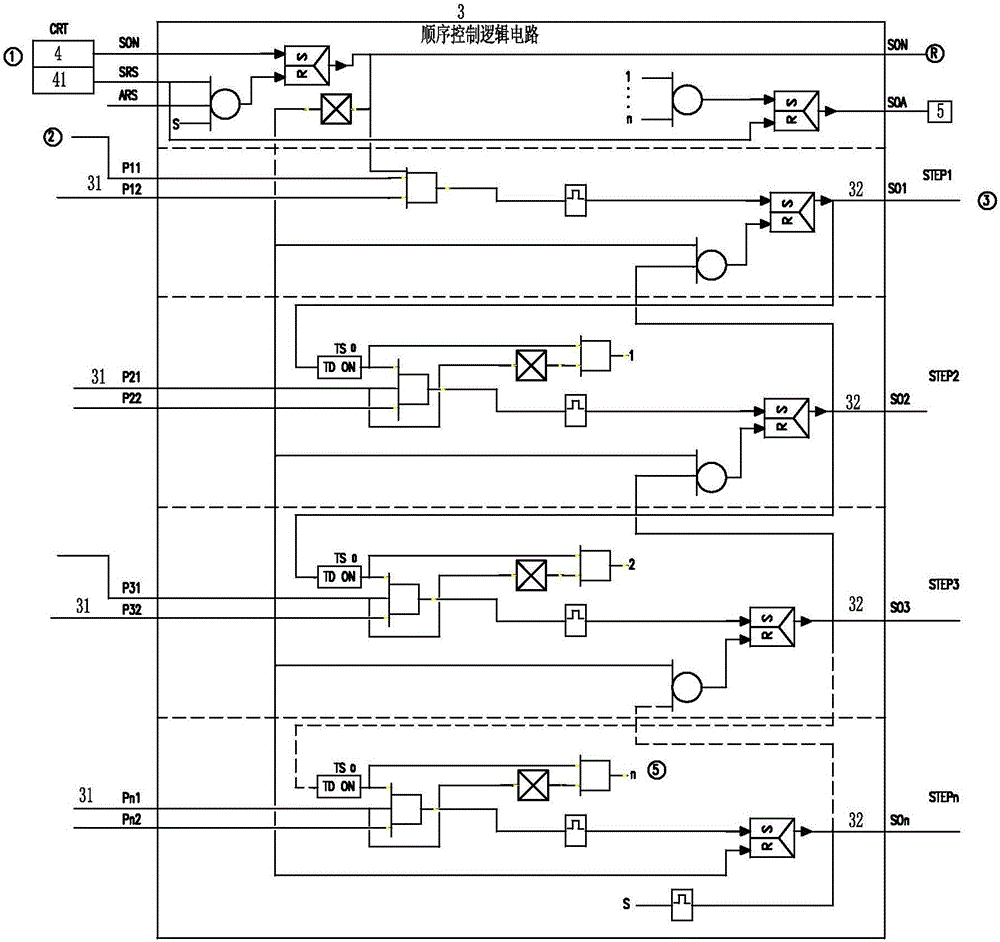

[0030] 1) A control logic circuit that integrates one or more auxiliary machines and their auxiliary equipment of a nuclear power plant together with the process system into a functional subgroup;

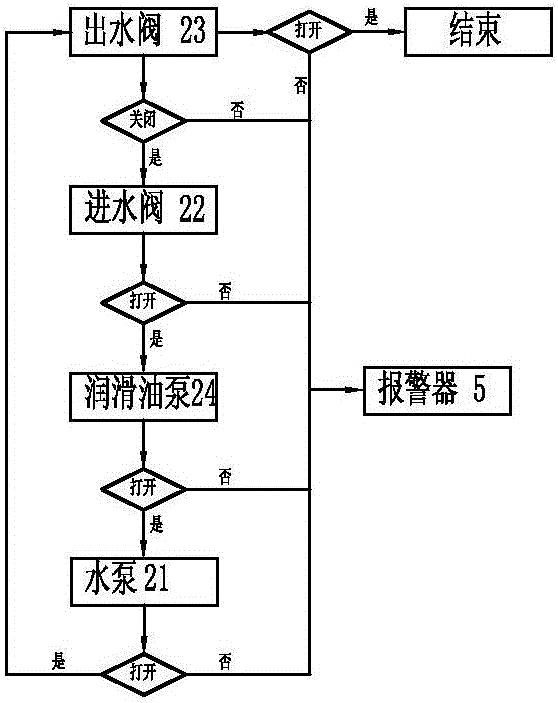

[0031] 2) According to the order and conditions required by the operation of auxiliary machines, set the operation sequence of auxiliary machines and related auxiliary equipment in the subgroup, and the feedback signal of the execution status of the previous auxiliary machine or auxiliary equipment that is started first as the next auxiliary machine or auxiliary equipment Program License Conditions.

[0032] In the method, the man-machine interface CRT of the DCS is provided with the start-up operation of the sub-functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com