Cast steel liquidity predicting method

A prediction method and fluidity technology, applied in the field of foundry, can solve the problems of increasing cost, prolonging product development and manufacturing cycle, lack of scientificity and reliability, etc., to achieve the effect of promoting digitalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: a method for predicting cast steel fluidity, comprising the following steps:

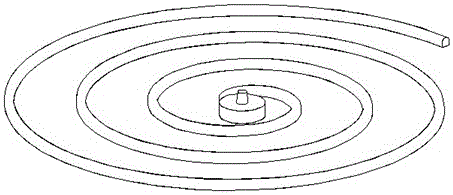

[0023] Step (1): Conduct spiral sample experiments with different grades of cast steel, and collect neural network training sample data. In this example, 26 grades of cast steel materials were selected. Under the condition of controlling the degree of superheat and consistent pouring speed (the degree of superheat is the liquidus temperature of the cast steel + 10°C, and the pouring speed is 0.01m / s), Spiral specimens (such as figure 1 Shown) pour molten steel, take the solid phase mass fraction of the sample when the mold is filled as the fluidity evaluation index w, the sample data includes the percentages of alloy components C, Fe, Mn, P, S and The liquidity evaluation index w, the obtained sample data are shown in Table 1 below:

[0024] Table 1 Neural network training sample data

[0025]

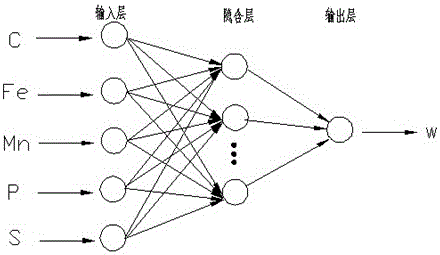

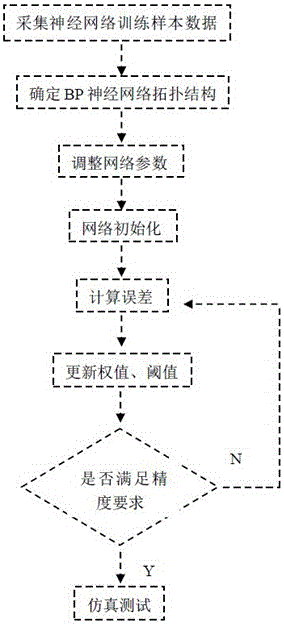

[0026] Step (2): Establish a neural network model for cast steel fluidity pred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com