Carbonization method

A carbonization furnace and process technology, used in chemical instruments and methods, by-product vaporization, special forms of dry distillation, etc., can solve the problem of inability to use carbonization devices, and achieve the effect of efficient carbonization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the carbonization method of the present invention will be described.

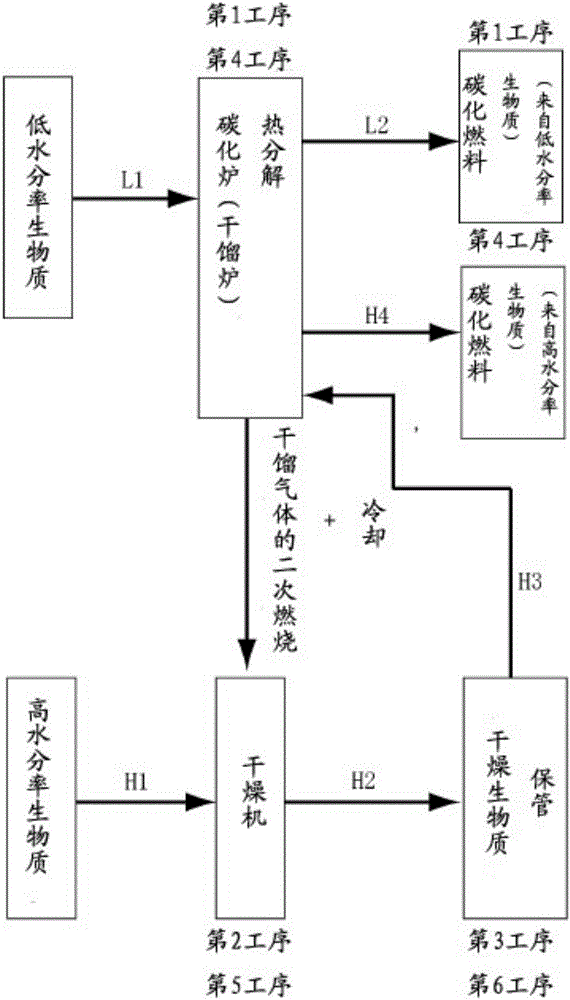

[0029] Such as figure 1 As shown, the carbonization method of the present invention includes at least the first to sixth steps, and can be carried out as it is without almost any improvement or addition of equipment to the existing carbonization device equipped with a dryer and a carbonization furnace (carbonization furnace). should be stated, figure 1 In the figure, the paths until the low-moisture biomass becomes carbonized fuel are marked as L1 and L2, and the paths until the high-moisture biomass becomes carbonized fuel are marked as H1-H4.

[0030] In the first step, low-moisture biomass is thermally decomposed in a carbonization furnace to obtain carbonized fuel and pyrolysis gas derived from low-moisture biomass.

[0031] Specifically, one or more types of low-moisture biomass with low moisture content are put into the carbonization furnace of the existing carbonization device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com