Lathe used for turning long rod class of parts

A technology of lathes and long rods, which is applied in the field of lathes for turning long rod parts, and can solve problems such as the clamping arm cannot clamp the workpiece, the stability is reduced, and the length-to-diameter ratio is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

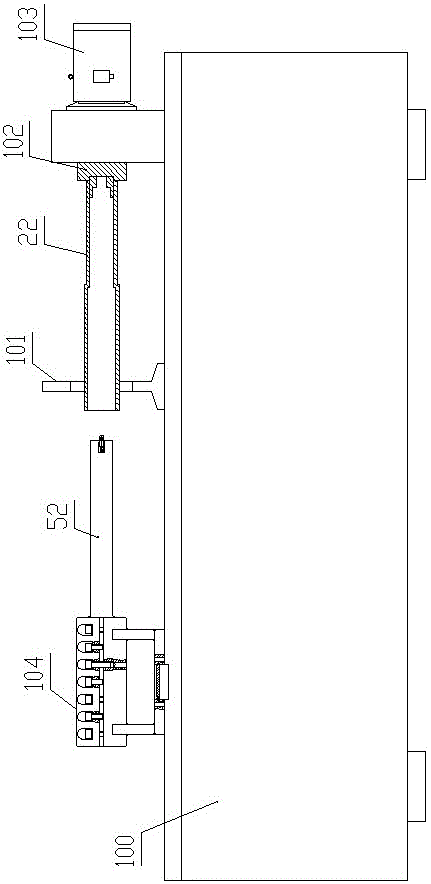

[0023] Such as figure 1 As shown, the lathe for turning long rod parts of the present invention includes a bed 100, a tool bar 52, a tool bar clamping device 104, a jaw type lathe center clamp 101, a chuck 102 and a motor 103, and the motor 103. The center clamper 101 and the tool bar clamping device 104 of the jaw type lathe are fixed on the bed 100, and the main shaft of the motor 103 is fixedly connected with the chuck 102;

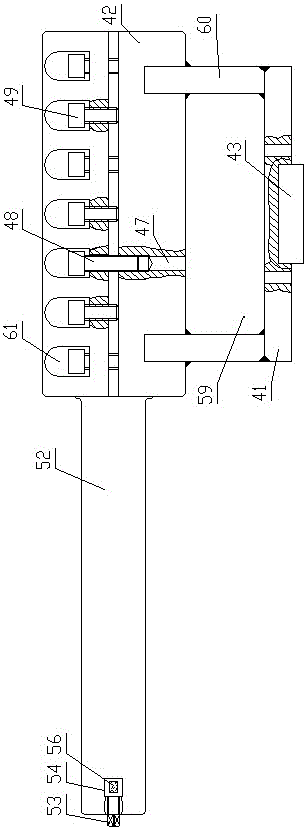

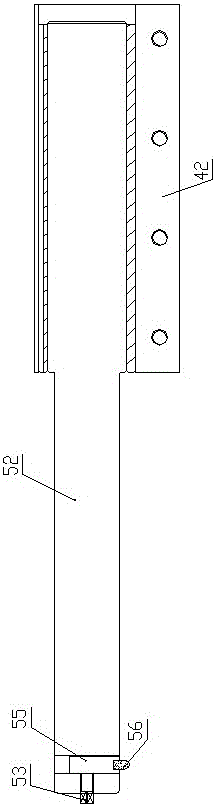

[0024] Such as Figure 2-4 As shown, the tool bar clamping device 104 includes a horizontally arranged base 41 and a tool bar cover 42. The bottom of the base 41 is embedded with a positioning block 43 protruding downward from the lower surface of the base 41. The knife rod cover 42 is fixedly connected, the knife rod cover 42 is a cylindrical structure, the center line of the knife rod cover 42 is horizontally arranged along the left and right directions, and the tool rod cover 42 is provided with a cylindrical mounting cavity 44 along the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com