Structure for reinforcing composite with metal meshes

A composite material and fine mesh technology, applied in the field of composite material structure, can solve problems such as catastrophic damage, front wheel detachment, and rider falling over

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

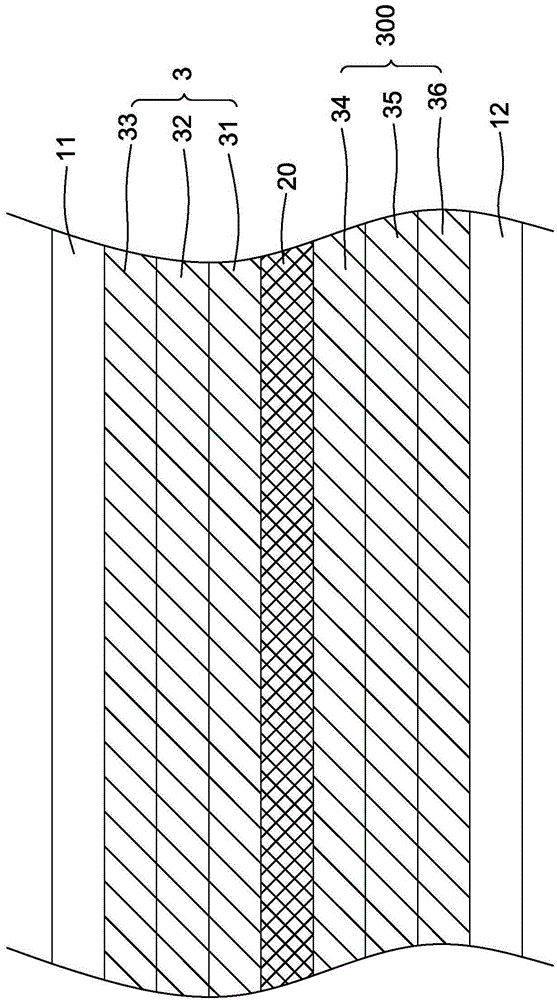

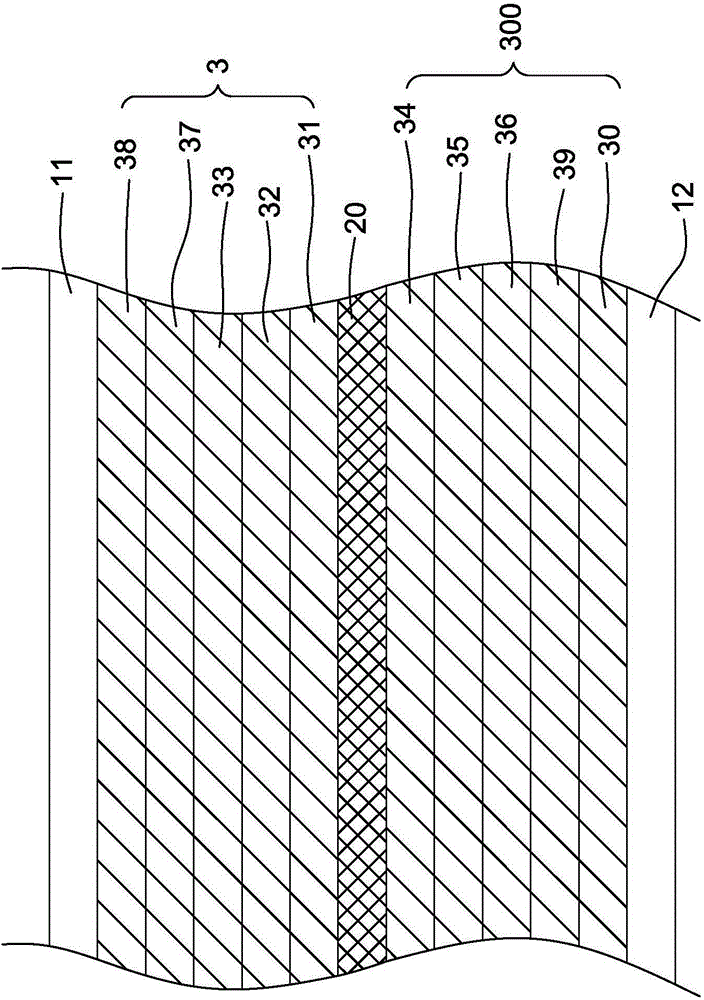

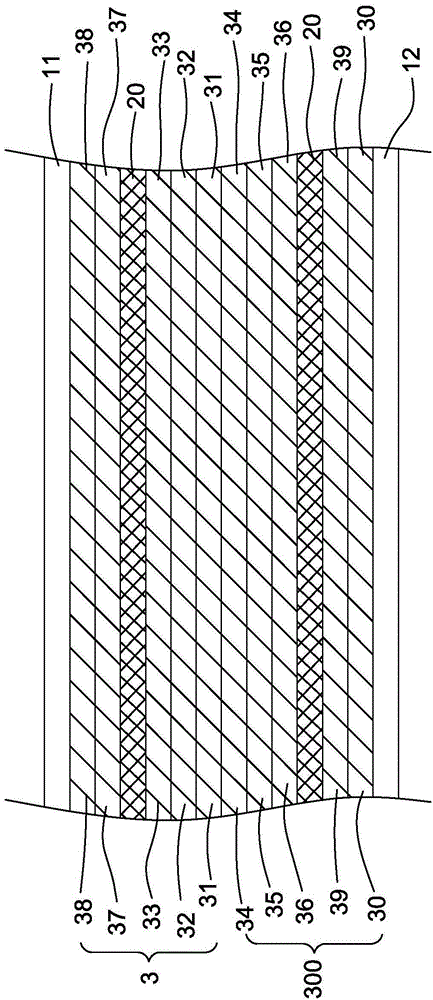

[0030] Please refer to figure 1 As shown, the present invention uses a fine metal mesh to strengthen the composite material structure, including a first composite material layer 11, a second composite material layer 12, a fine metal mesh 20, and an upper side cladding fiber body 3 1. The lower side multilayer fiber body 300, wherein:

[0031] The fine metal mesh 20 , the upper cladding fiber body 3 , and the lower cladding fiber body 300 are located between the first composite material layer 11 and the second composite material layer 12 .

[0032] In the figure of the embodiment, the fine metal mesh 20 is combined between the upper side multilayer fiber body 3 and the lower side multilayer fiber body 300, and the first composite material layer 11 is combined with the upper side multilayer fiber body 3 On the outside, the second composite layer body 12 is bonded to the outside of the lower composite layer fiber body 300 .

[0033] In the present invention, the materials of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com