Method for catalytic ozonization treatment of acidic nitrobenzene wastewater

A technology of nitrobenzene wastewater and ozonation, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve problems such as poor stability, reduced catalyst activity, equipment blockage, etc., and achieve reduced thickness , reduce economic costs, and efficiently remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

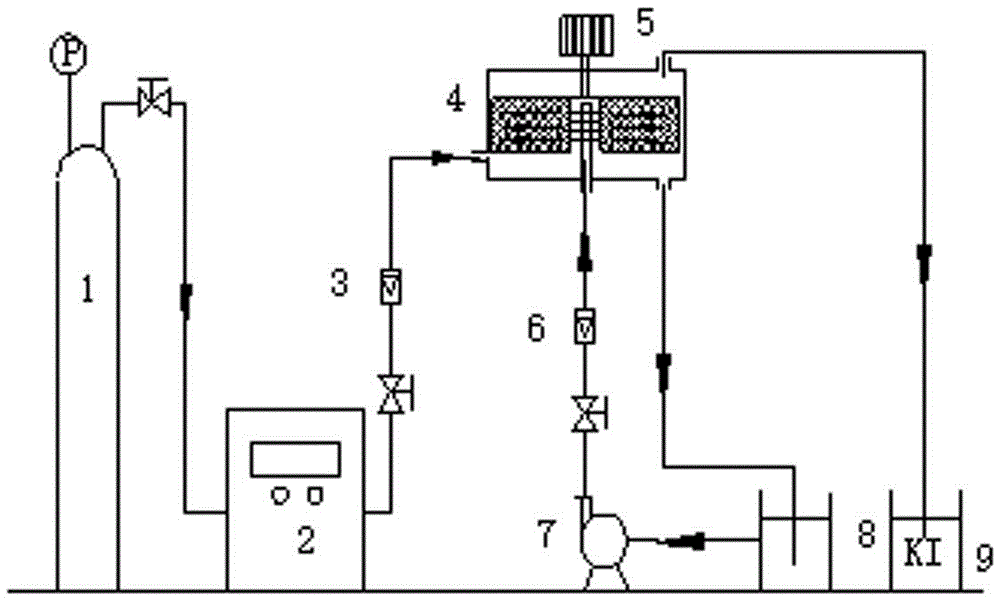

[0030] use figure 1 The process shown is to treat acidic nitrobenzene simulated wastewater. The concentration of nitrobenzene in the wastewater is 150mg / L. The pH of the solution is adjusted to 1 with sulfuric acid and sodium hydroxide, the supergravity factor is 300, and the liquid flow rate is 40L / h. A certain amount of MnSO was added to 4 ﹒ h 2 O Make the concentration of manganese ions 400 mg / L, the flow rate of ozone-containing gas is 50 L / h, the ozone concentration is 10 mg / L, and a certain amount of H is added every 5 minutes 2 o 2 makes H 2 o 2 The concentration is 20 mg / L. The removal rate of nitrobenzene reached more than 89.23% after 30 minutes of circulating treatment; at this time, the removal rate of TOC reached more than 52%; and RPB-O 3 / H 2 o 2 Compared with the new technology, the ozone utilization rate is increased by 8%, and the treatment cost is reduced by 10%.

Embodiment 2

[0032] use figure 1 The process shown is to treat acidic nitrobenzene simulated wastewater. The concentration of nitrobenzene in the wastewater is 150mg / L. The pH of the solution is adjusted to 5 with sulfuric acid and sodium hydroxide, the supergravity factor is 80, and the liquid flow rate is 140L / h. Add Mn(NO 3 ) 2 . 4H 2 O Make the concentration of manganese ions 200 mg / L, the flow rate of ozone-containing gas is 70 L / h, the ozone concentration is 100 mg / L, and a certain amount of H is added every 5 minutes 2 o 2 make H 2 o 2 The concentration is 3 mg / L. The removal rate of nitrobenzene reached more than 91.75% after 25 minutes of circulating treatment; at this time, the removal rate of TOC reached more than 54%; and RPB-O 3 / H 2 o 2 Compared with the advanced technology, the ozone utilization rate is increased by 10%, and the treatment cost is reduced by 15%.

Embodiment 3

[0034] use figure 1 The process shown is to treat acidic nitrobenzene simulated wastewater. The concentration of nitrobenzene in the wastewater is 150mg / L. The pH of the solution is adjusted to 2 with sulfuric acid and sodium hydroxide, the supergravity factor is 10, and the liquid flow rate is 100L / h. MnSO 4 . h 2 O Make the concentration of manganese ions 100 mg / L, the flow rate of ozone-containing gas is 75L / h, the ozone concentration is 40mg / L, and a certain amount of H is added every 5 minutes 2 o 2 make H 2 o 2 The concentration of nitrobenzene was 10 mg / L, and the removal rate of nitrobenzene reached more than 99.51% after 15 minutes of circulating treatment; at this time, the removal rate of TOC reached more than 65%; and RPB-O 3 / H 2 o 2 Compared with the new technology, the ozone utilization rate is increased by 20%, and the treatment cost is reduced by 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com