Car plant cleaner

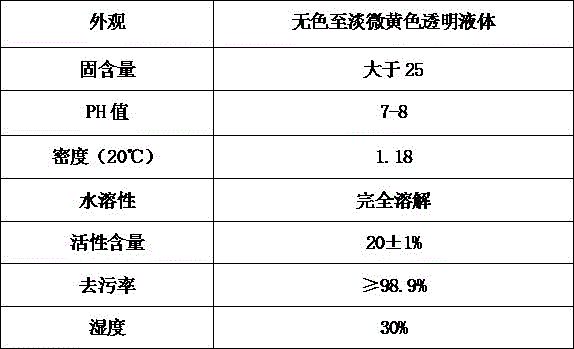

A cleaning agent, plant technology, applied in the directions of detergent compounding agent, detergent composition, non-surface-active detergent composition, etc., can solve the economic loss of vehicle owners, reduce the service life of automobiles, and tighten paint layers or boards. and other problems, to achieve the effect of reducing the number of washing and maintenance, saving maintenance costs, and easy to water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A car plant cleaner, prepared from the following raw materials in parts by weight: 6 parts of Sapindus chinensis extract, 3 parts of glycerin, 12 parts of lemon active enzyme, 4 parts of Coptis rhizome concentrate, 2 parts of Tribulus terrestris concentrate, wherein lemon The active enzyme is extracted from lemon slices by pickling, fermenting, and filtering and alcoholizing. The fermentation ratio of lemon active enzyme is: 3 parts of lemon, 10 parts of water, and 1 part of salt. The pickling time is 2 months, and the active enzyme is extracted by filtering and alcoholizing. ; The Coptis chinensis concentrate and the Tribulus terrestris concentrate are obtained through biochemical extraction techniques.

Embodiment 2

[0015] A car plant cleaner, prepared from the following raw materials in parts by weight: 8 parts of Sapindus chinensis extract, 2 parts of glycerin, 10 parts of lemon active enzyme, 5 parts of Coptidis Rhizome concentrate, 2 parts of Tribulus terrestris concentrate; wherein, lemon The active enzyme is extracted from lemon slices by pickling, fermenting, and filtering and alcoholizing. The fermentation ratio of lemon active enzyme is: 3 parts of lemon, 10 parts of water, and 1 part of salt. The pickling time is 3 months, and the active enzyme is extracted by filtering and alcoholizing. ; The Coptis chinensis concentrate and the Tribulus terrestris concentrate are obtained through biochemical extraction techniques.

Embodiment 3

[0017] A car plant cleaner, prepared from the following raw materials in parts by weight: 10 parts of Sapindus chinensis extract, 3 parts of glycerin, 12 parts of lemon active enzyme, 6 parts of Coptis chinensis concentrate, 1 part of Tribulus terrestris concentrate, wherein lemon The active enzyme is extracted from lemon slices by pickling, fermenting, and filtering and alcoholizing. The fermentation ratio of lemon active enzyme is: 3 parts of lemon, 10 parts of water, and 1 part of salt. The pickling time is 3 months, and the active enzyme is extracted by filtering and alcoholizing. ; The Coptis chinensis concentrate and the Tribulus terrestris concentrate are obtained through biochemical extraction techniques.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com