Method for Obtaining Uniform Titanium Coil Structure Using Titanium Shavings

A titanium scrap and uniform technology, which is applied in the field of titanium coil manufacturing, can solve the problems such as the limitation of the deformation amount of cold rolling and exceeding the deformation amount range, and achieve the effect of solving the problem of recycling, increasing the benefit and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

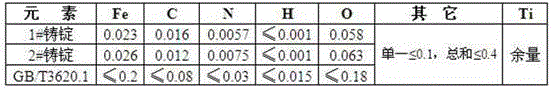

[0036] The EB furnace of ALD company in Germany was used for smelting, and the same batch of O-grade sponge titanium was selected to be 9t, 5t of pure sponge titanium was smelted in a furnace of 1#, and 4t of sponge titanium + 1tTA1 titanium scraps were smelted in a furnace of 2#. The composition is shown in Table 1.

[0037] Table 1 Chemical composition of TA1 ingot (wt.%)

[0038]

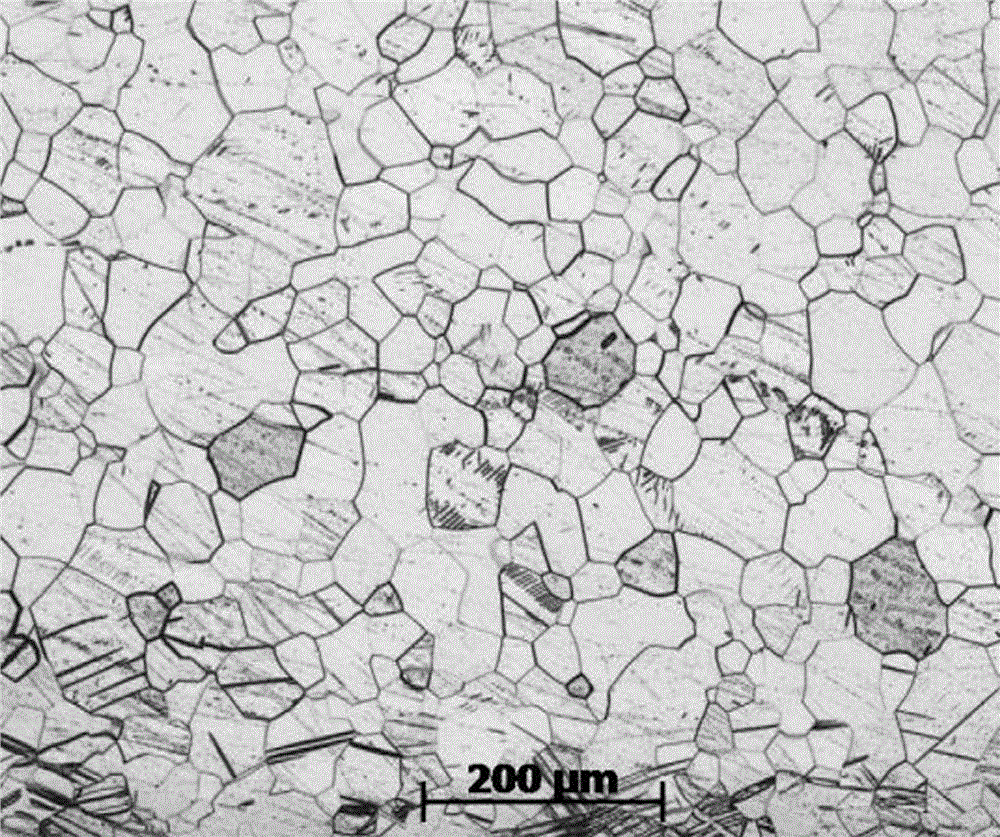

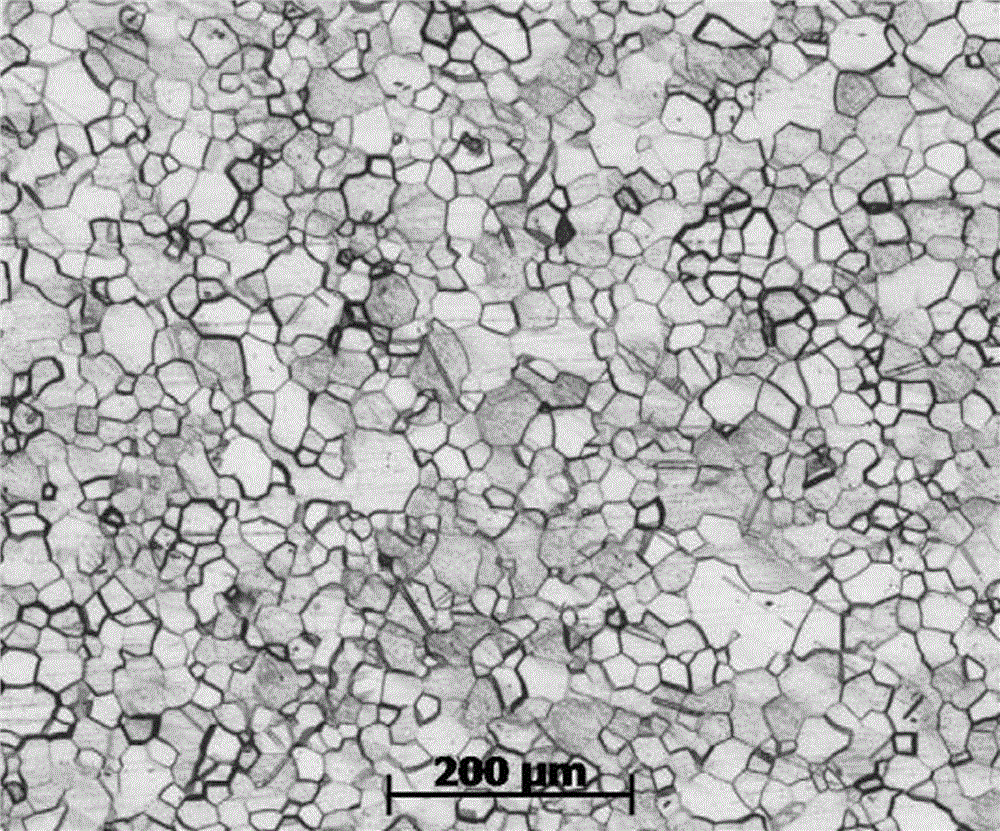

[0039] The thickness of 1# and 2# cast ingots is about 190mm after face milling, the thickness of the coil after hot rolling is 4.5mm, and the shot blasting and pickling after annealing, the grain size is 7.5 and 8 respectively, and the grain size is relatively uniform; they are all the same The cold rolling of the process, the cold rolling deformation is 31%, and the thickness of the finished product is 3.1mm. After atmospheric annealing at 640°C, the grain size of the 1# coil is uneven, and the grain size is about 7 grades. See figure 1 ; The grain size of the 2# coil is relatively uniform, ...

Embodiment 2

[0043] Adopt the method similar to embodiment 1 to prepare the TA1 ingot containing 30%TA1 titanium chips, O content 0.067%, N content 0.0083%, Fe0.031%, C0.019%, other impurity element content is qualified; Rolled to 4mm, the grain size is about 8 grades, and the grains are relatively uniform.

[0044] After the surface of the hot-rolled coil is ground, it is cold-rolled, the deformation rate is 25%, and the deformation rate of the pass is ≤10%, and the 2.0mm thick cold-rolled titanium coil is obtained. The hardness and strength of the coil during the cold-rolling process are greater, and the rolling force Compared with the 1# coil in Example 1, the increase is more than 10%; after rolling, surface treatment is carried out to remove rolling oil, etc., followed by annealing in a vacuum bell furnace, the annealing temperature is 650 ° C, and the holding time is 8 hours. After annealing, it is cooled to below 200°C, and then it is air-cooled; then it is tempered and rolled to im...

Embodiment 3

[0047] Adopt the method similar to embodiment 1 to prepare the TA1 ingot containing 10%TA1 titanium chips, O content 0.061%, N content 0.0065%, Fe0.025%, C0.013%, other impurity element content is qualified; Rolled to 3.5mm, the grain size is about 8 grades, and the grains are relatively uniform.

[0048] After the surface of the hot-rolled coil is ground, it is cold-rolled, the deformation rate is 57%, and the pass deformation rate is ≤ 14%, and a 1.5mm thick cold-rolled titanium coil is obtained. The rolling force during the cold-rolling process is higher than that of the 1# coil in Example 1. Larger; after rolling, surface treatment is carried out to remove rolling oil, etc., followed by annealing in a vacuum bell furnace, the annealing temperature is 660 ° C, after annealing, it is cooled to below 200 ° C, and it is air-cooled after being out of the furnace; then it is tempered and rolled to improve the shape, Reduce unevenness; straighten and then cut into required plates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com