Wear-resistant and anti-corrosion sucker rod connectors, tubing connectors

A technology of connectors and sucker rods, applied in the direction of drill pipes, drill pipes, casings, etc., can solve problems such as large differences, failure of wear-resistant and anti-corrosion effects, coating cracks, etc., and achieve the effect of improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

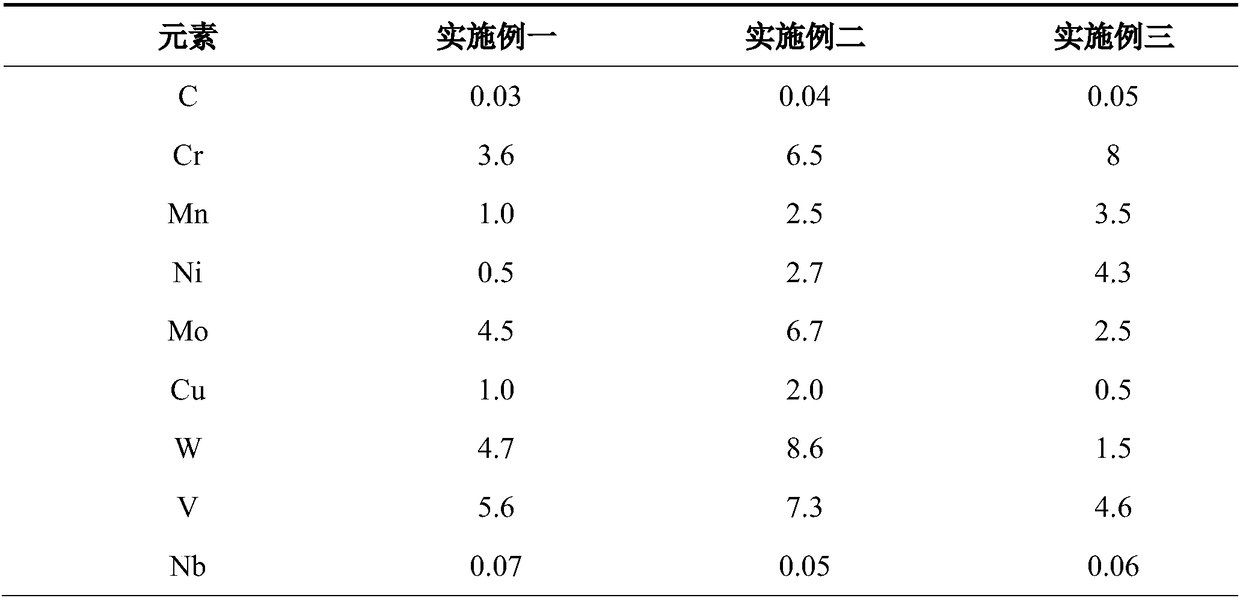

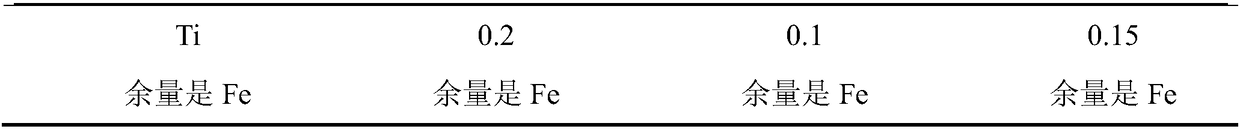

[0016] The present invention is a wear-resistant and anticorrosive sucker rod connector. The surface of the sucker rod connector substrate is covered with a coating with a thickness of 0.15-0.6mm by thermal spraying technology, and the composition of the coating is calculated as a mass percentage :C: 0.03-0.05, Cr: 3.6-8, Mn: 1.0-3.5, Ni: 0.5-4.3, Mo: 2.5-6.7, Cu: 0.5-2.0, W: 1.5-8.6, V: 3.5-7.3, Nb : 0.05-0.07, Ti: 0.1-0.2, the balance is Fe.

[0017] An oil pipe connector of the present invention is coated with a coating with a thickness of 0.15-0.6 mm on the surface of the base body of the oil pipe connector by thermal spraying technology. The composition of the coating is calculated by mass percentage: C: 0.03-0.05, Cr: 3.6-8, Mn: 1.0-3.5, Ni: 0.5-4.3, Mo: 2.5-6.7, Cu: 0.5-2.0, W: 1.5-8.6, V: 3.5-7.3, Nb: 0.05-0.07, Ti: 0.1- 0.2, the balance is Fe.

[0018] The C in the steel of the present invention is basically controlled at 0.03-0.05%, and there is only a small amount of C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com