Insulation and water seepage compound culvert for deep cutting in alpine permafrost region and its construction method

A construction method and technology in permafrost areas, which are applied to deep cutting thermal insulation and water seepage compound ditch and its construction field in alpine permafrost areas, can solve problems such as the inability to prevent the influence of the upper layer of warm air and the inability to guarantee the thermal stability of the lower layer of frozen soil, etc. The effect of protecting thermal stability, high construction efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

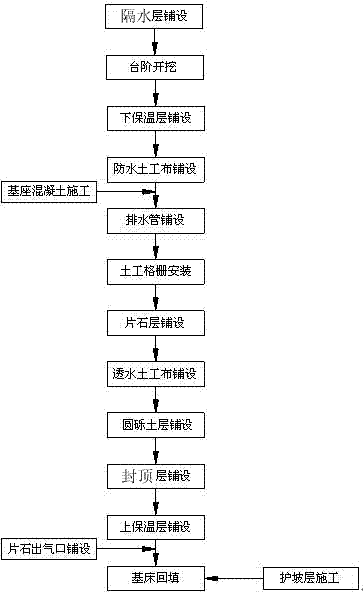

[0035] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

[0036] The filling and digging construction technology, formwork setting technology and concrete pouring construction technology involved in the embodiments of the present invention all belong to conventional methods, so they will not be repeated in this implementation. The present invention focuses on the embodiments of the structure related to the present invention .

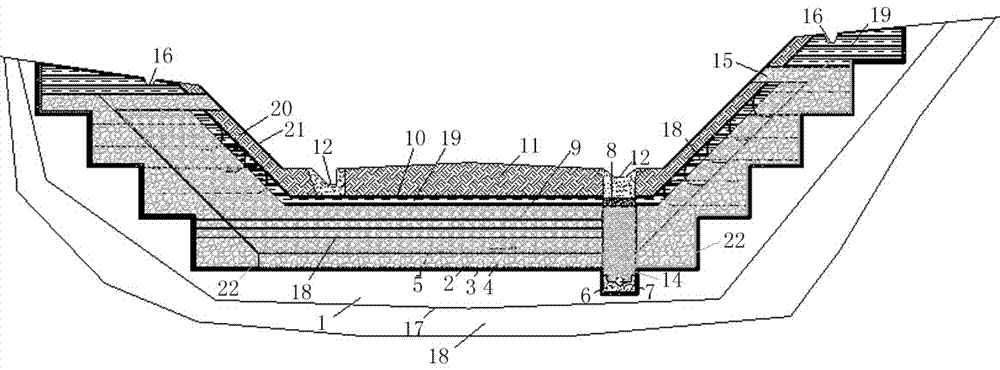

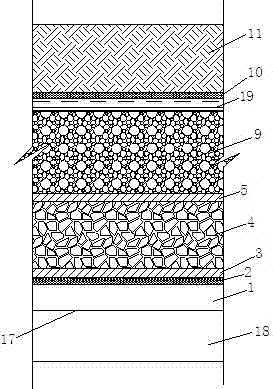

[0037] Such as figure 1 and figure 2 As shown, the thermal insulation and water seepage composite culvert of the deep road cutting in the alpine permafrost region of the present invention includes a plane section and a slope section, and the thermal insulation and water seepage composite culvert includes a water-proof layer 1, a lower thermal insulation layer 2, a waterproof geotextile 3, a stone layer 4, Non-woven geote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com