Horizontal hole or inclined hole drilling tool lifting system

A lifting system and horizontal hole technology, applied in the field of lifting systems, can solve the problems of high resistance of horizontal holes or inclined holes, inability to press drilling tools, high labor intensity, etc., so as to improve efficiency, reduce labor intensity, and work safely and reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

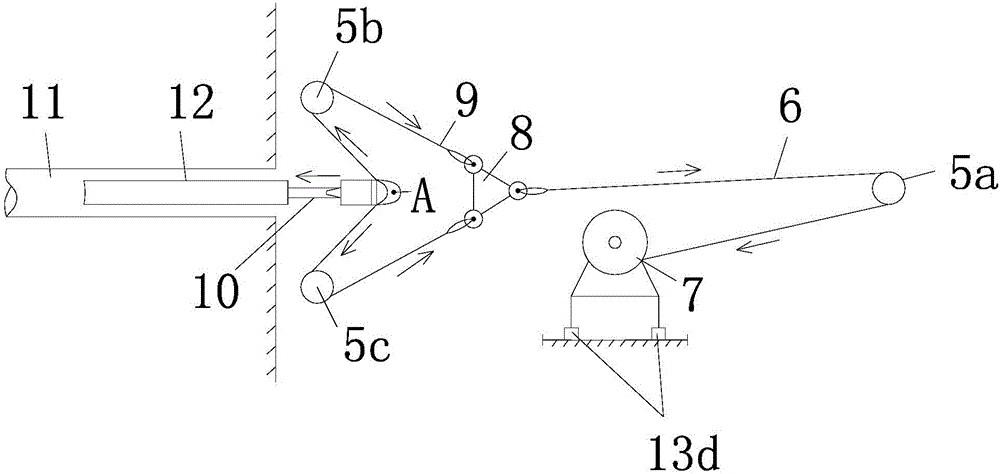

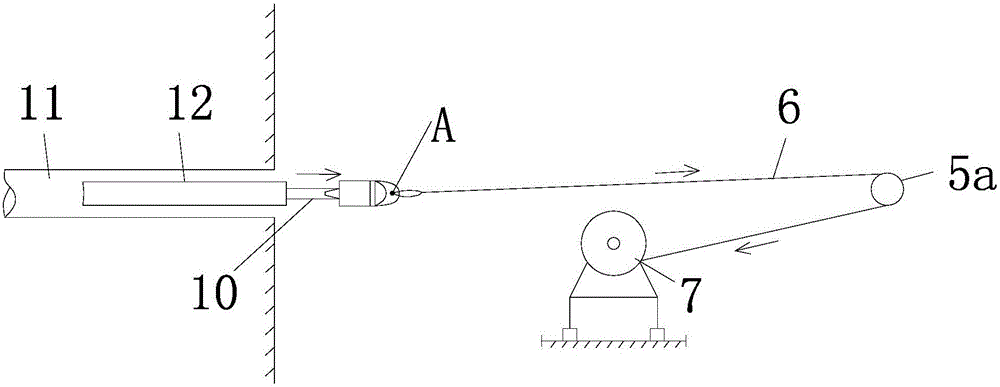

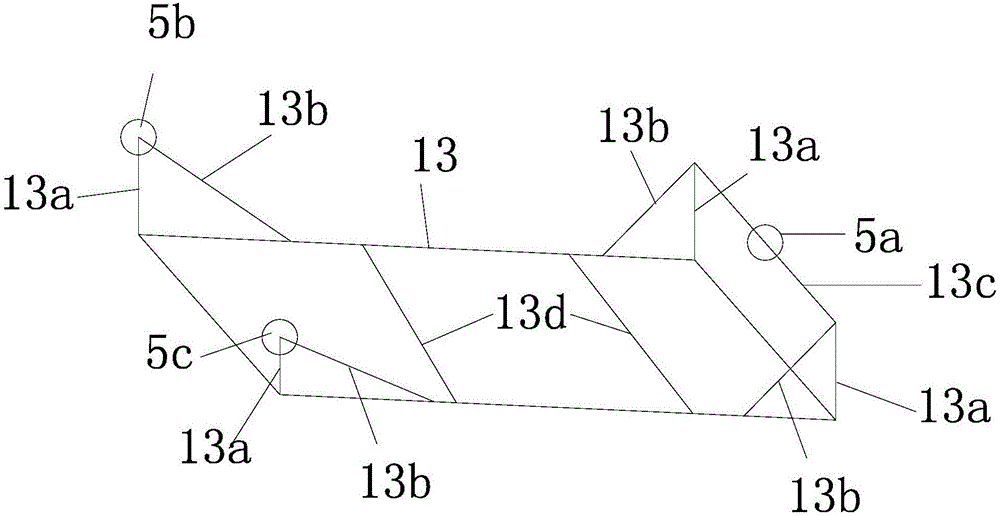

[0031] combine figure 1 — image 3 As shown, a horizontal hole or inclined hole drilling tool lifting system is mainly composed of an underframe 13, a first fixed pulley 5a, a second fixed pulley 5b, a third fixed pulley 5c, a first steel wire rope 6, a second steel wire rope 9, a triangular Connecting ring 8, winch 7 and special joint A etc. are formed.

[0032] The first fixed pulley 5a, the second fixed pulley 5b, and the third fixed pulley 5c are installed above the underframe 13 by respective mounting brackets and arranged in an isosceles triangle on the top view projection, wherein the first fixed pulley 5a is located far away from the borehole One end of 11, the second fixed pulley 5b, the third fixed pulley 5c are of the same height and are located on the side close to the borehole 11. Hoist 7 is installed in the middle part of underframe 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com