GLV and fresh air independent temperature-humidity control system and mounting chamber thereof

An independent control and fresh air system technology, applied in heating and ventilation control systems, ventilation systems, heating and ventilation safety systems, etc., can solve the problems of water accumulation, waste of energy utilization, low comfort, etc., to reduce system performance consumption, good air flow field, and the effect of ensuring air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

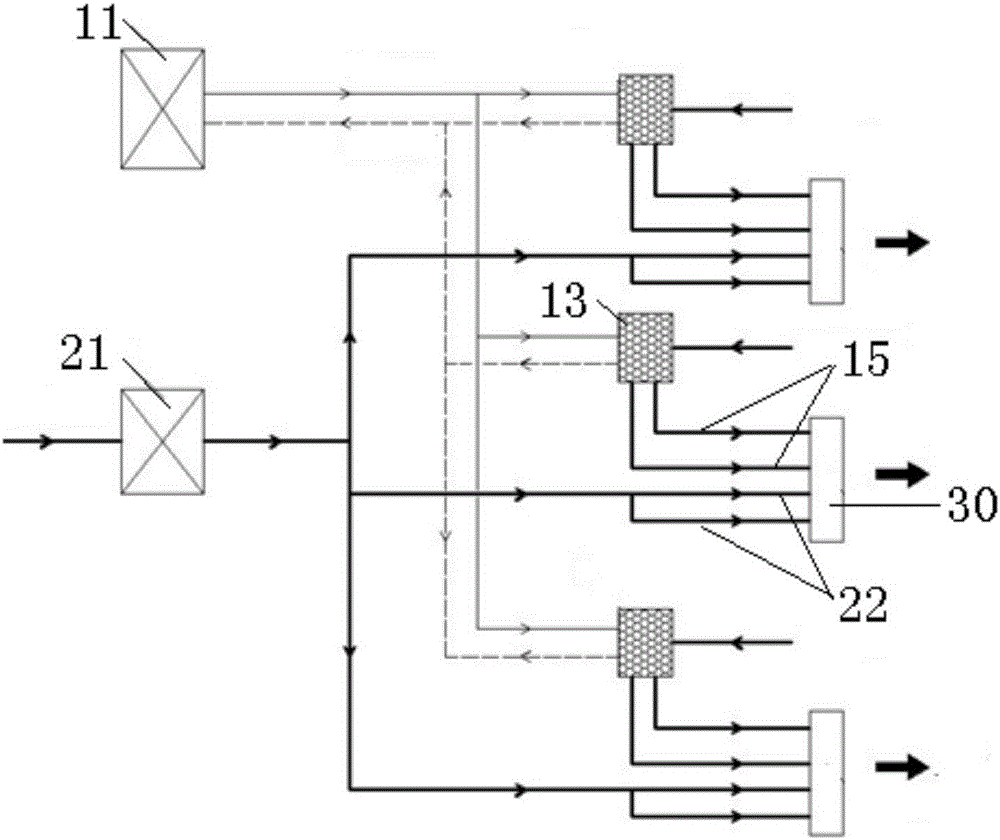

[0037] Such as figure 1 and figure 2 As shown, Embodiment 1 discloses an independent temperature and humidity control system for GLV and fresh air, including a GLV system and a fresh air system, wherein the GLV system is used to deal with indoor sensible heat load, and the fresh air system is used to deal with indoor latent heat load.

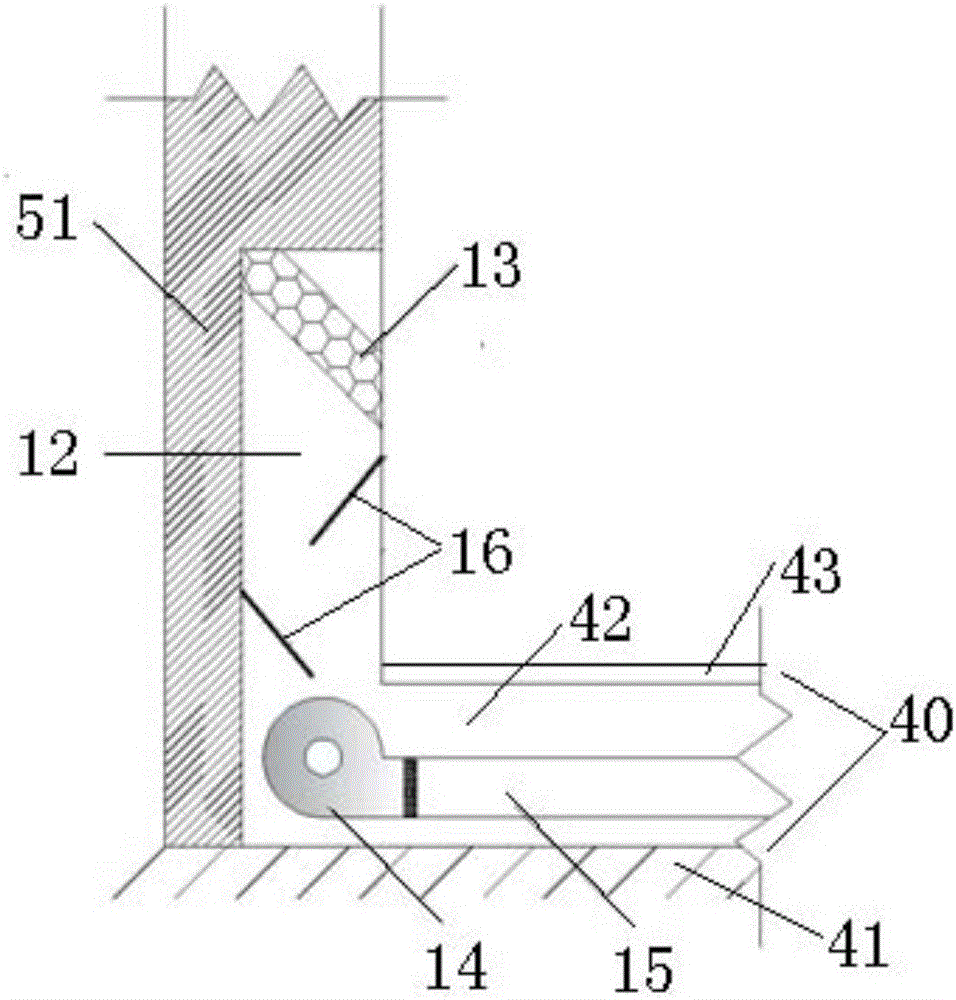

[0038]Among them, the GLV system includes a GLV outdoor unit 11 and three GLV indoor units 12, and the GLV indoor unit 12 communicates with two air supply ducts 15, wherein the GLV indoor unit 12 includes a casing and a micro-channel switch arranged in the casing. Heater 13, muffler baffle 16, air blower 14; the casing is provided with a circulating air inlet; the micro-channel heat exchanger 13 is connected to the GLV outdoor unit 11 through refrigerant pipes, and the micro-channel heat exchanger 13 is used to cool the circulating air. Cooling treatment; the sound-absorbing baffle 16 is located between the microchannel heat exchanger 13 and ...

Embodiment 2

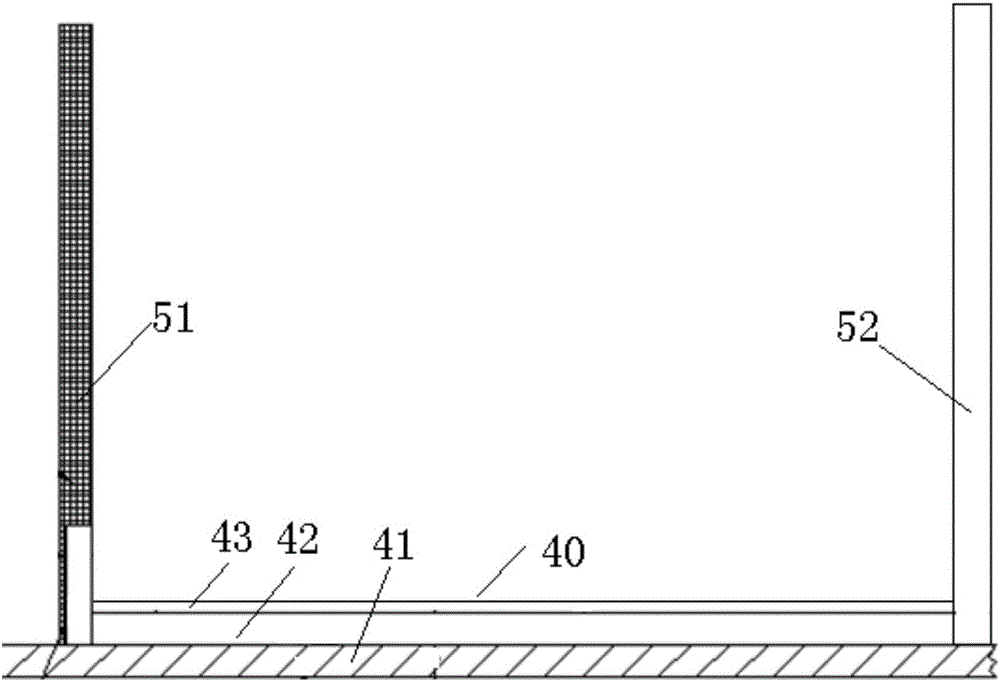

[0045] Such as figure 1 , figure 2 and image 3 As shown, Embodiment 2 discloses a GLV and fresh air temperature and humidity independent control system installation room and the GLV and fresh air temperature and humidity independent control system described in Embodiment 1, wherein the installation room includes a floor 40 and is arranged on the floor 40 The first side wall 51 and the second side wall 52 on the top, and the first side wall 51 is set opposite to the second side wall 52; the circulating air inlet is set on the first side wall 51, and the air supply outlet and the fresh air outlet are both set on on the floor 40 , and both the air supply outlet and the fresh air outlet are close to the junction of the floor 40 and the second side wall 52 .

[0046] Specifically, the floor 40 includes a cement floor 41, an overhead floor 42 and a wooden floor 43, and the cement floor 41, the overhead floor 42, and the wooden floor 43 are arranged sequentially from bottom to to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com