Three-dimensional pulsating heat pipe phase change material coupling energy storage system

A phase change material, pulsating heat pipe technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc. Market prospects and effects of environmental protection values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

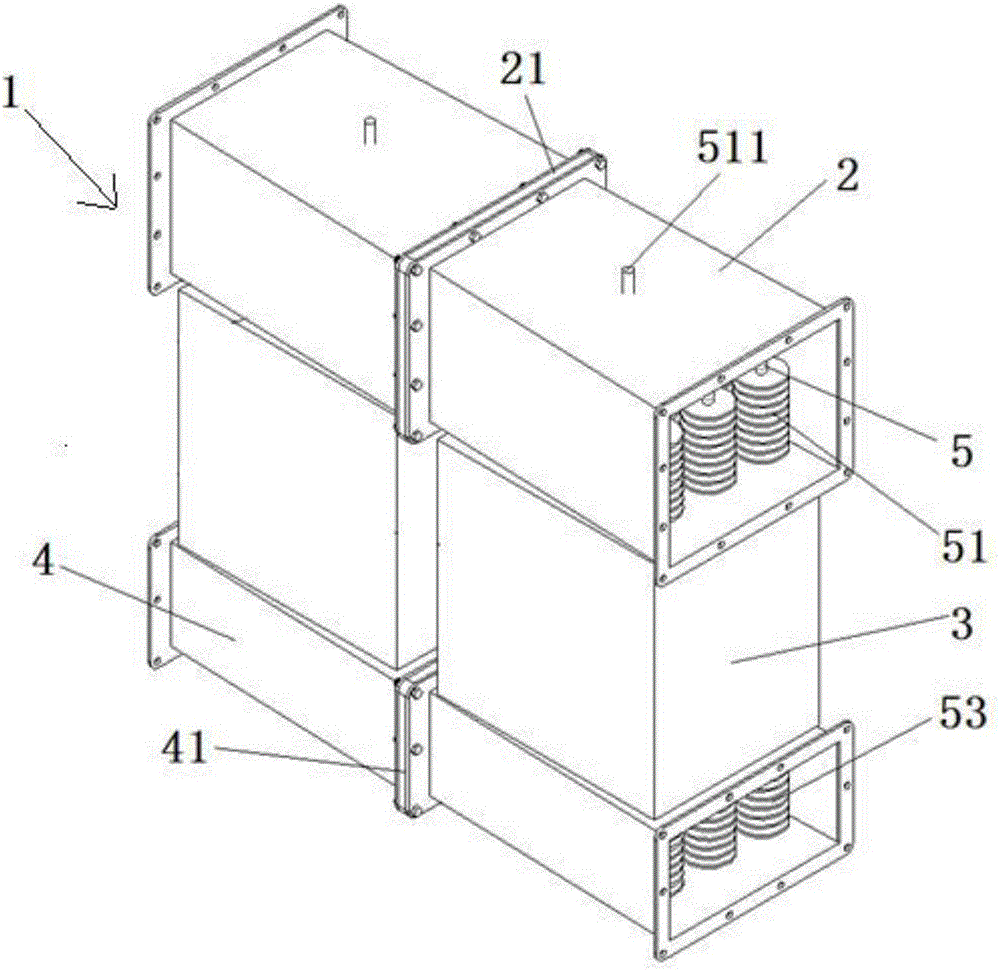

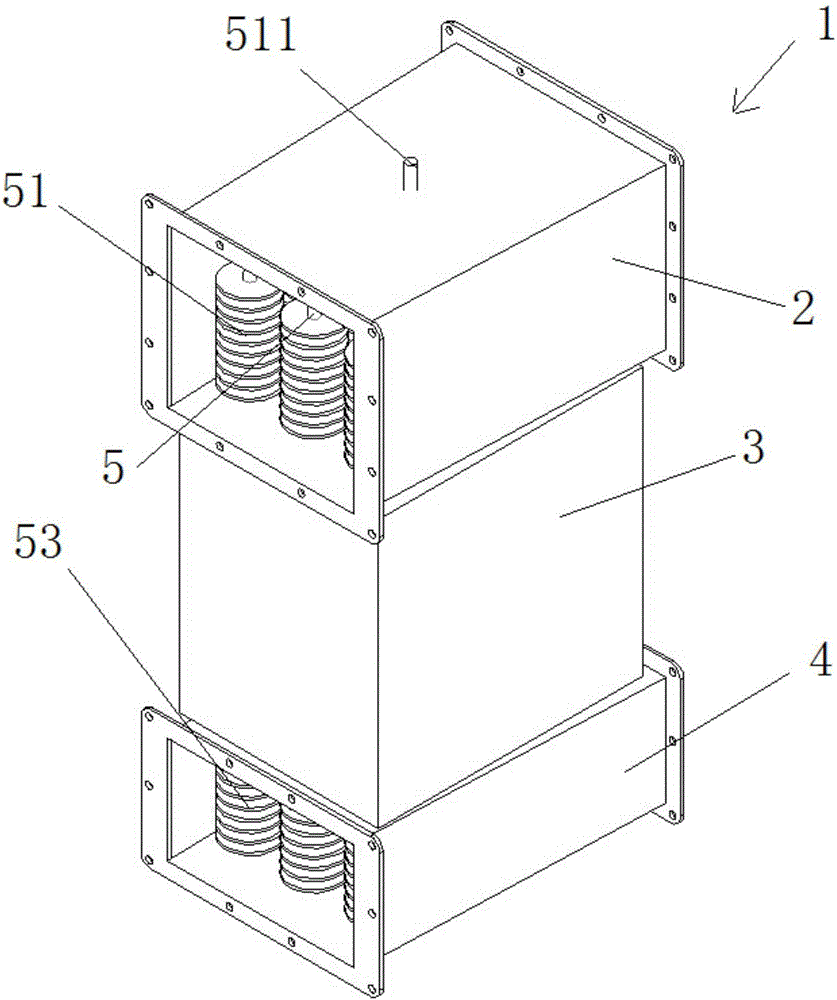

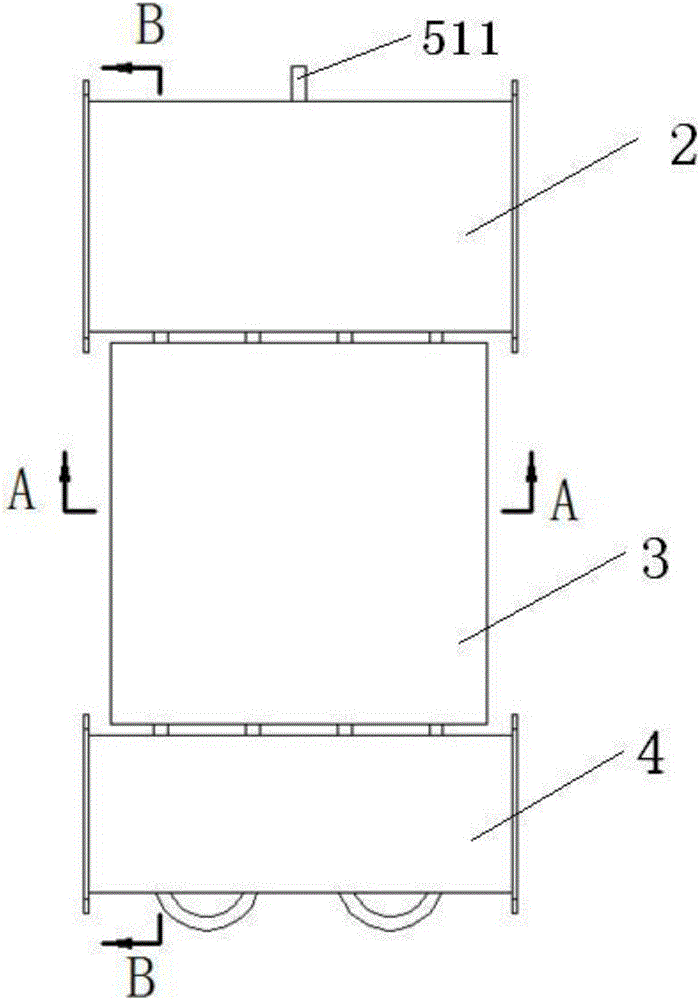

[0022] As shown in the drawings, a three-dimensional pulsating heat pipe phase change material coupling energy storage system includes more than two energy storage sub-modules 1, and the energy storage sub-module 1 includes a heat release flow channel 2, an energy storage box 3, and a heat charging flow channel 4. The pulsating heat pipe 5; the heat releasing runner 2 is welded together with one end of the energy storage box 3, and the other end of the energy storage box 3 is welded together with the heat charging runner 4, or connected by other sealed connection methods. Together; the pulsating heat pipe 5 is provided with upper fins 51, middle fins 52 and lower fins 53 in sequence from top to bottom, and the upper fins 51 are placed in the heat release runner 2, and the middle fins 52 are placed in the energy storage box body 3, and the lower fin 53 is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com