Biological bone small-dimensional sample three-point bending test device

A technology of three-point bending and testing equipment, which is applied in the direction of measuring equipment, using stable bending force to test the strength of materials, instruments, etc., can solve the problems of reducing free bending constraints, large friction, and low test efficiency, and achieve reduction Error influence, improve measurement accuracy, solve the effect of roller splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

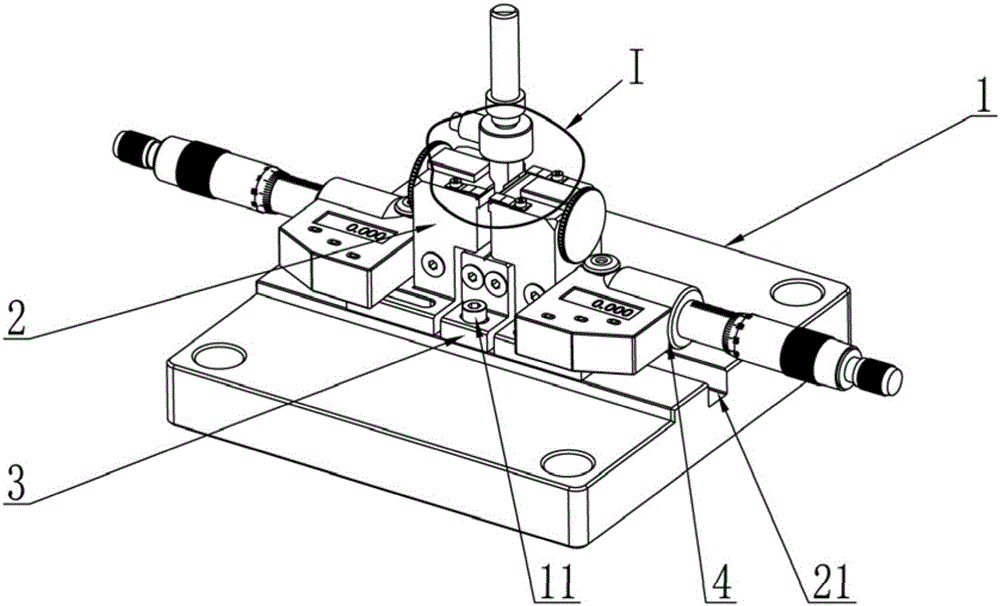

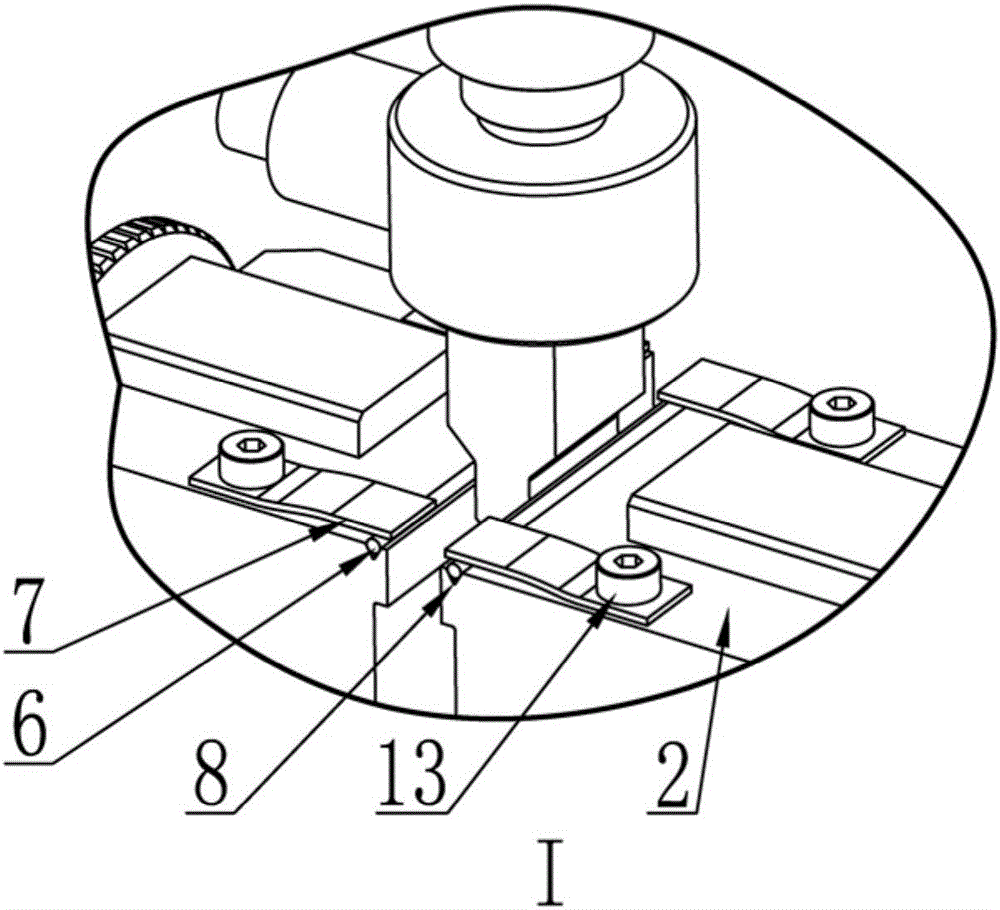

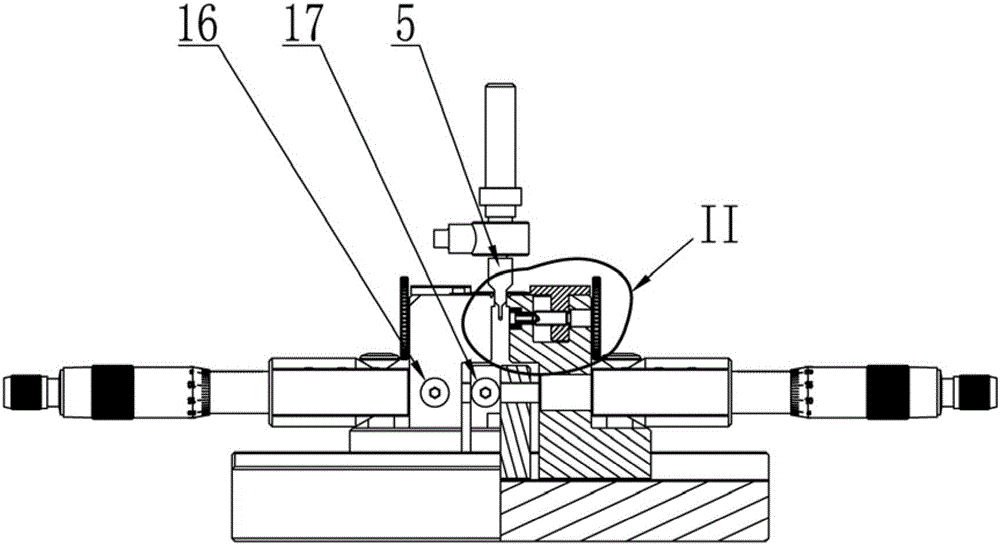

[0040] The three-point bending test device for small-sized bone samples of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] like figure 1 As shown, a three-point bending test device for small-sized bone samples includes a base 1, a support base 2, a center block 3, a straight-forward electronic differential head 4, an indenter 5, a roller 6, a pressure piece 7, and a V-shaped positioning Slot 8, T-shaped block 9, adjusting dial 10, center block fastening screw 11, support seat fastening screw 12, pressing piece fastening screw 13, measuring head 14, fixed sleeve 15, fixed sleeve fastening screw 16. Measuring head fastening screw 17, adjusting dial fastening sleeve 18, adjusting dial fastening bolt 19, T-shaped block guide groove 20, support seat guide rail groove 21, dial positioning hole 22. Among them, the support seat guide rail groove 21 is provided in the middle of the base 1 to realize the linear sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com