Supercritical anti-corrosion testing device and testing method

A technology for testing devices and testing methods, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of uncontinuous long-term testing, blockage of feed pipes, etc., to reduce content, reduce The effect of small chance of inorganic salt clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

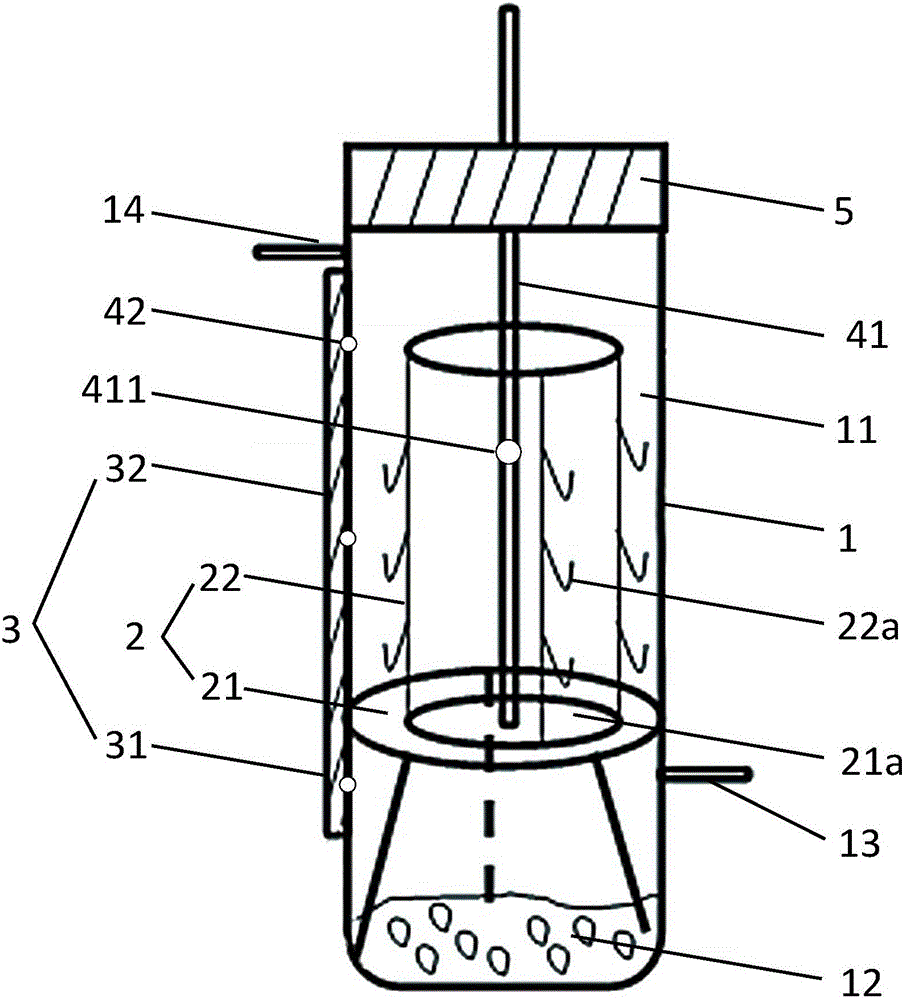

[0042] In order to further illustrate the supercritical anti-corrosion testing device provided by the embodiment of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

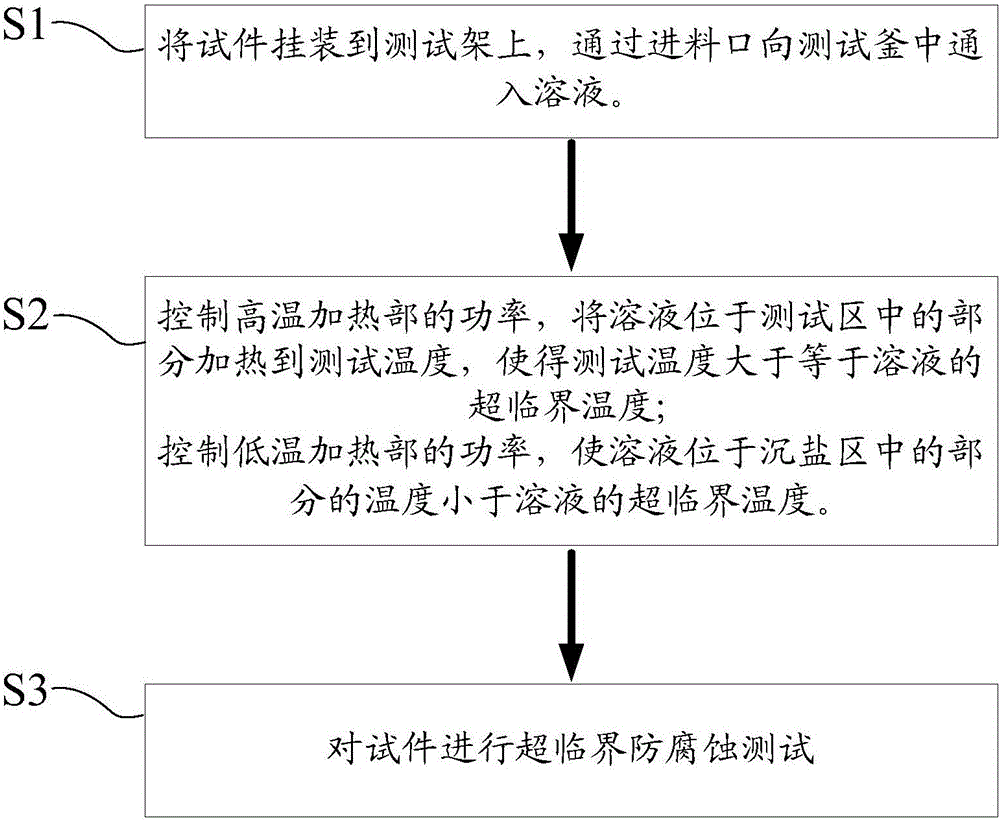

[0043] see figure 1 , the supercritical anti-corrosion testing device that the embodiment of the present invention provides comprises: test kettle 1, is provided with test rack 2 in the test area 11 of test kettle 1, and test kettle 1 is provided with feed inlet 13 and discharge outlet 14; From the bottom of the kettle 1 to the top direction, the side wall of the test kettle 1 is also provided with an adjustable heating device 3; The salt area 12 is opposite, and the heating temperature of the low-temperature heating part 31 is lower than the supercritical temperature of the solution; the high-temperature heating part 32 is opposite to the test area 11 of the test kettle 1, and the heating temperature of the high-temperature heating part 32 is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com