Heat transfer analysis method and system for recovering slag waste heat based on physical method

A technology of physical method recovery and thermal analysis, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that it is difficult to reflect the real process of particle cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

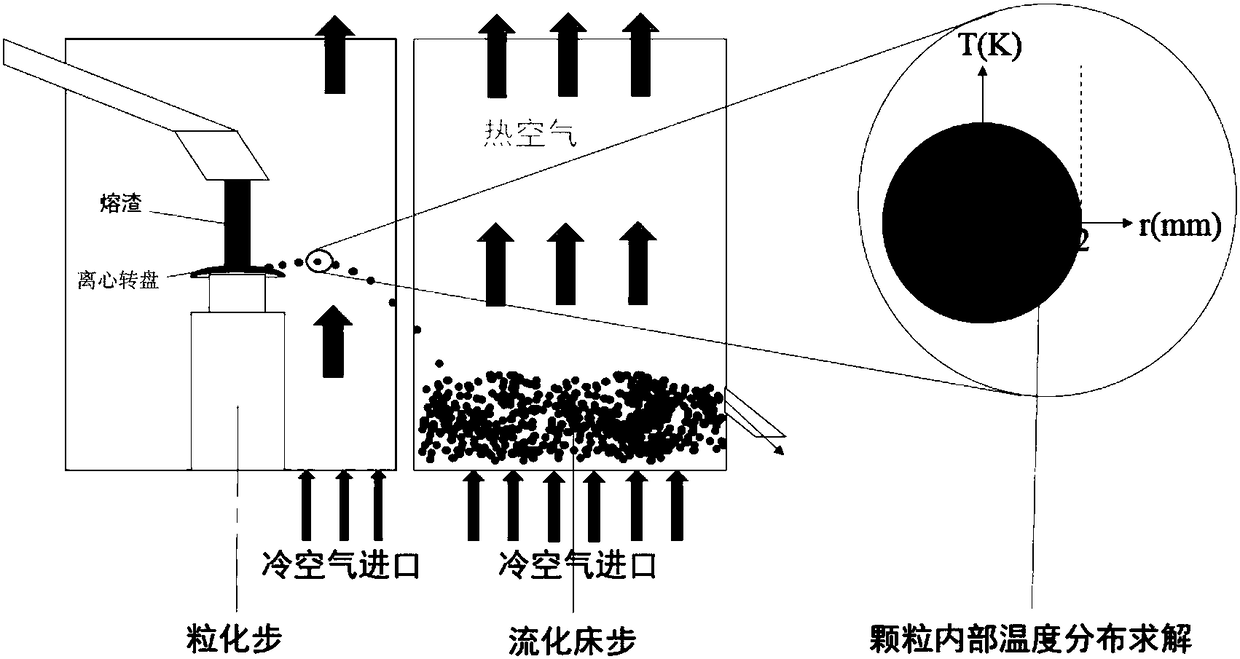

[0052] In this calculation example, the radius of the slag flight area (fluidized bed step) is 1.1m, the mass flow rate of slag is 5kg / s (ie 18t / h), and the mass flow rate of air is 2kg / s. The initial temperature of the slag is 1500°C (1773K), and the basic physical properties are shown in Table 1. In the granulation step, the slag is broken into particles with a diameter of 1.5mm, the initial velocity is 2m / s, and the throwing angle is 15°.

[0053] Table 1 Basic physical properties of slag

[0054]

[0055] Step 1: Analyze the overall flow field and the cooling curve of the particles through the CFD model.

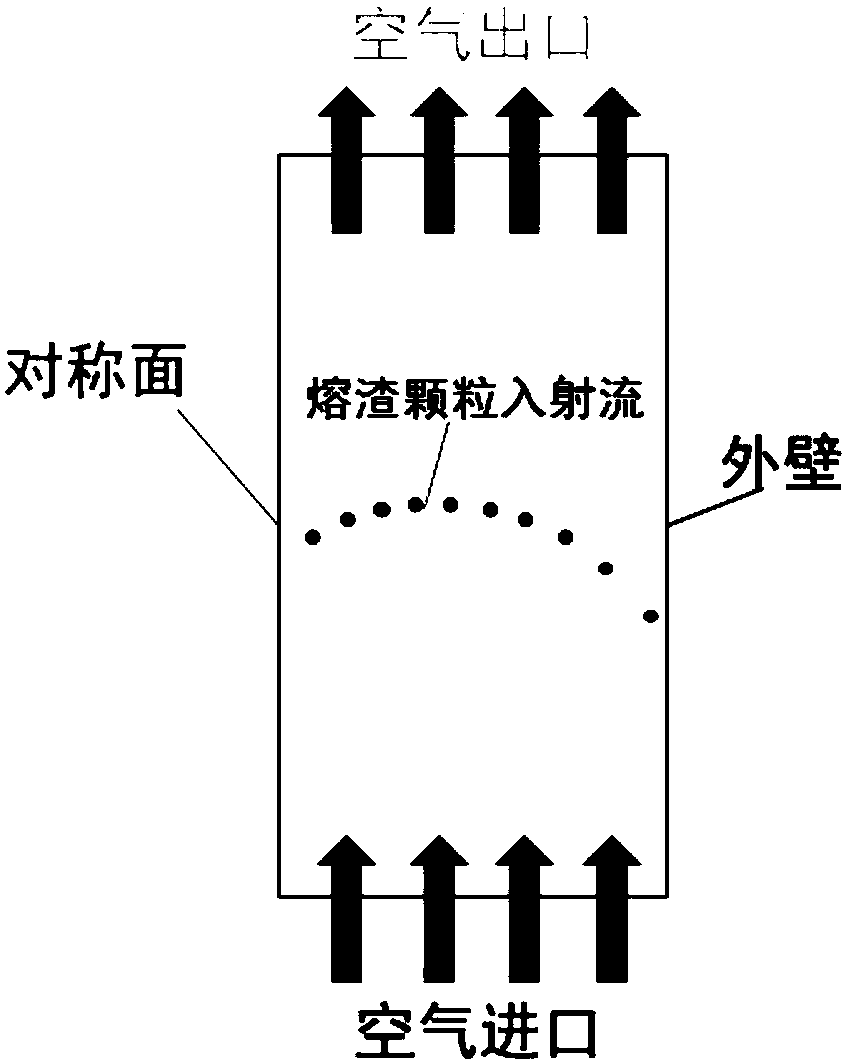

[0056] (1) Calculating the cooling curve of slag particles during flight by Lagrangian discretization (DPM model). Due to the symmetry of the area, only half of the area can be calculated. The computational domain has a width of 1.1m and a height of 9m, divided into 24750 square structured grids. The average temperature of the air mass flow at a height of 5m is tak...

Embodiment (2

[0068] With the process of embodiment (1), but particle diameter is reduced to 0.5mm. Compared with Example (1), the effect of particle size on the recovery process of slag waste heat can be obtained.

Embodiment (3

[0070] With the process of embodiment (1), but the air flow of two steps is all doubled. The obtained particle cooling curve is as Figure 14 shown. Compared with Example (1), the influence of the air flow rate on the slag waste heat recovery process can be obtained.

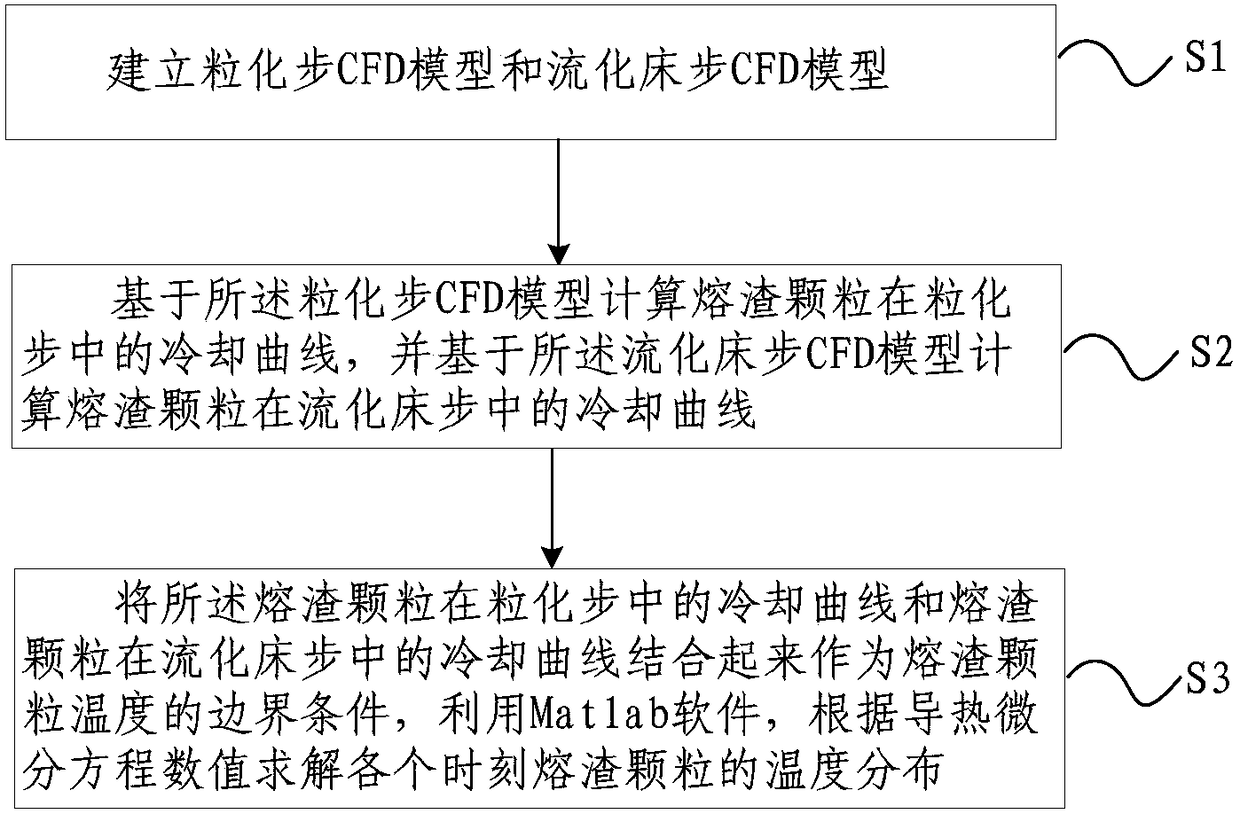

[0071] see Figure 15 , this embodiment discloses a heat transfer analysis system based on physical methods for recovering slag waste heat, including:

[0072] Model building unit 1, used to set up a granulation step CFD model and a fluidized bed step CFD model;

[0073] Curve calculation unit 2, used to calculate the cooling curve of slag particles in the granulation step based on the granulation step CFD model, and calculate the cooling curve of the slag particles in the fluidized bed step based on the fluidized bed step CFD model curve;

[0074] The distribution calculation unit 3 is used to combine the cooling curve of the slag particles in the granulation step and the cooling curve of the slag particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com