Method for manufacturing GaP rough surface of four-element chip

A rough surface, chip technology, applied in the field of optoelectronics, can solve the problems of GaP not easy to corrode, not easy to corrode, etc., to achieve the effect of improving quality, stable quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

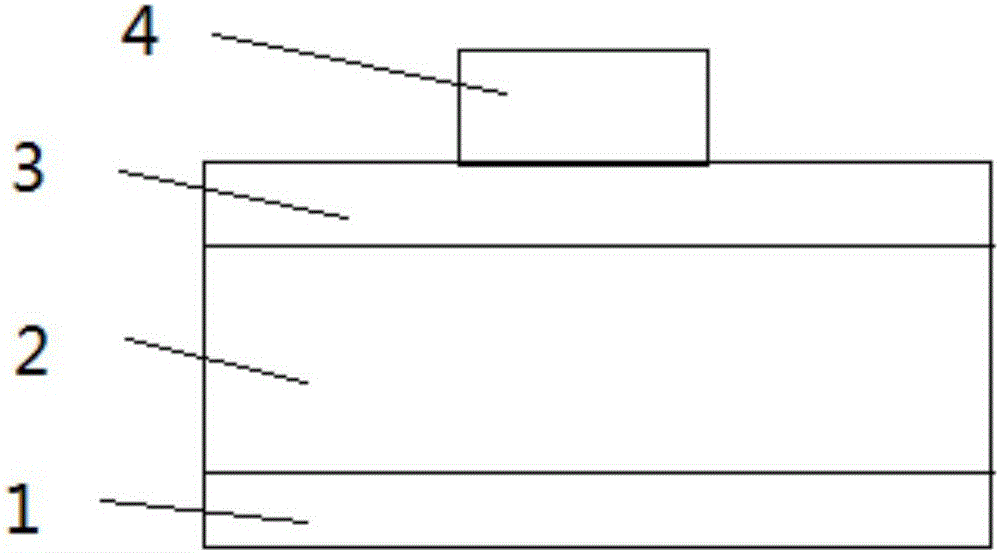

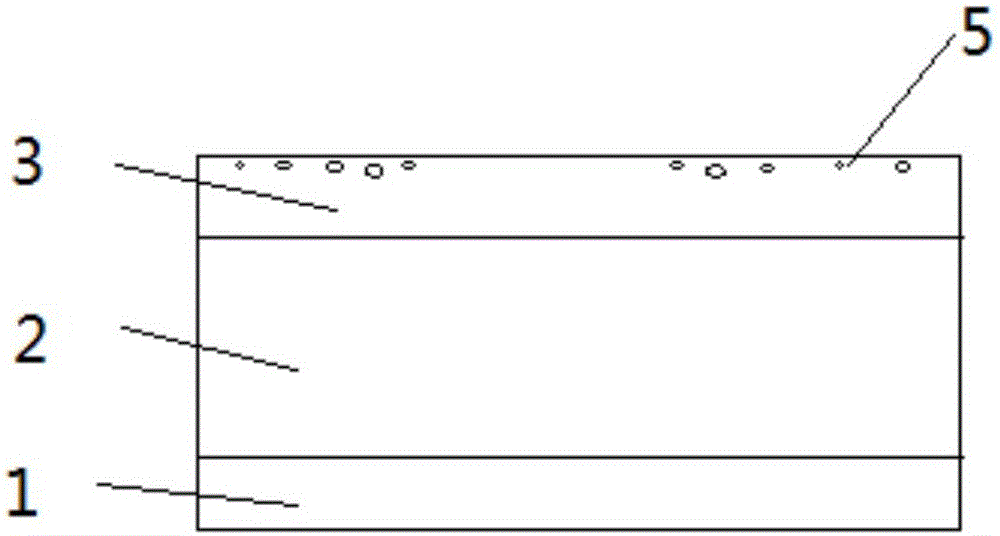

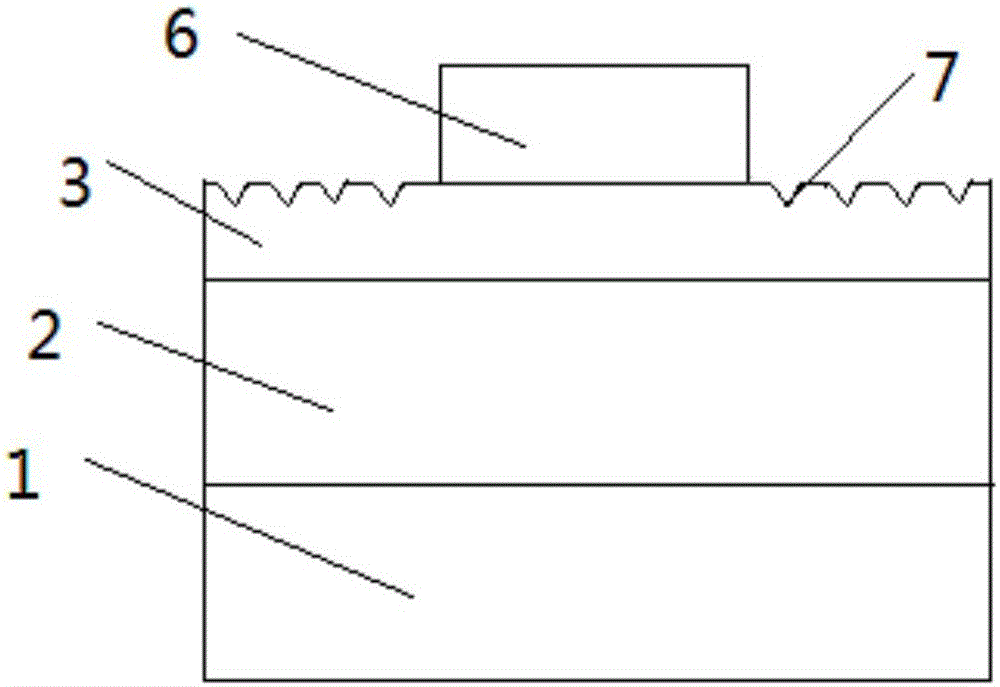

[0036] A method for preparing a GaP rough surface of a quaternary chip, comprising sequentially performing sandblasting roughening treatment and wet etching treatment on the GaP surface 3 to obtain a GaP rough light-emitting surface 7, the roughness range of the GaP rough light-emitting surface 7 : 0.5 μm<Ra<2 μm.

Embodiment 2

[0038] A method for preparing a GaP rough surface of a quaternary chip as described in Example 1, the difference is that the grit used in the sand blasting roughening treatment is: silicon carbide particles with a diameter of 12500 mesh to 15000 mesh.

Embodiment 3

[0040] The preparation method of the GaP rough surface of a kind of quaternary chip as described in embodiment 2, its difference is, described GaP surface is roughened by sandblasting 5-20 minutes, the included angle of sandblasting normal line and described GaP surface 70-90°, sandblasting speed 0.125-0.5cm / min, sandblasting grit density 0.5-2g / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com