Hybrid excitation three-phase brushless synchronous generator based on full wave induction excitation

A technology of synchronous generator and mixed excitation, which is applied in the direction of controlling the generator through the change of the magnetic field and connecting with the control/drive circuit. It can solve the problems of affecting the normal operation of the load and the inability to adjust the permanent magnet generator, and achieves a simple and flexible structure. The effect of magnetic adjustment ability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and embodiments.

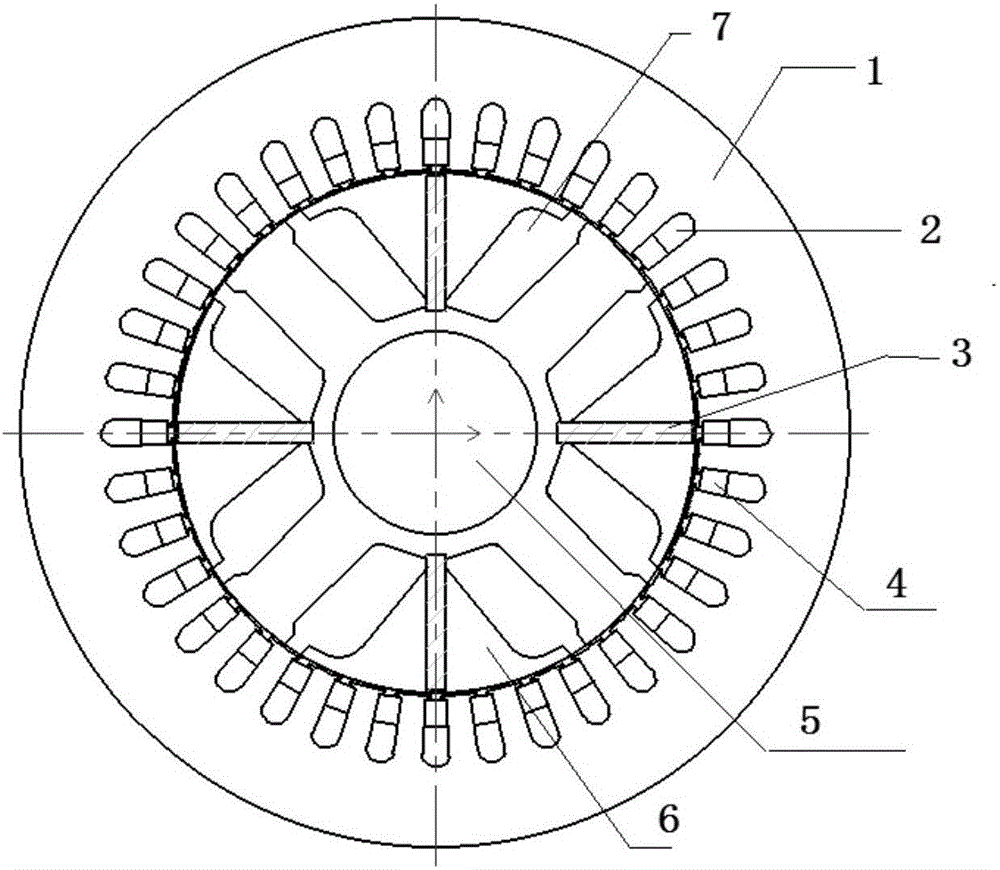

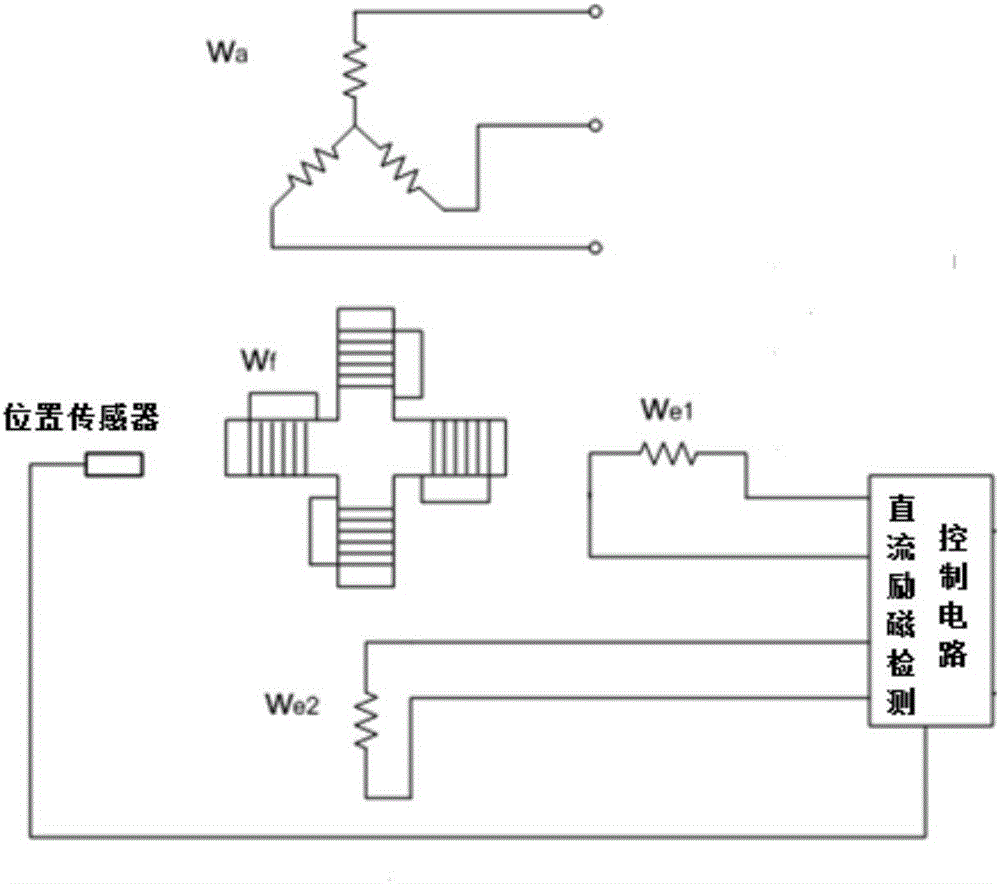

[0025] Such as figure 1 As shown, a hybrid excitation three-phase brushless generator based on full-wave induction excitation includes a casing in which a stator and a rotor are coaxially installed. The stator core is basically the same as an ordinary permanent magnet synchronous generator. A three-phase distributed armature winding and a single-phase excitation winding are embedded on the stator core. The excitation winding and a DC excitation detection control circuit form an excitation regulator. Both the rotor induction winding and the tangentially magnetized permanent magnets are embedded in the rotor core, and the permanent magnets are embedded in the closed slender slot of the rotor core. The rotor induction winding is a concentrated winding, which is embedded and wound in the large open slot of the rotor core and shorted by itself. The number of poles of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com