Low-junction-temperature photovoltaic junction box and chip assembly therefor

A junction box and junction temperature technology, applied in the field of low junction temperature photovoltaic junction boxes, can solve the problems of easy failure, high junction temperature of diodes, short life of photovoltaic modules in junction boxes, etc. Good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

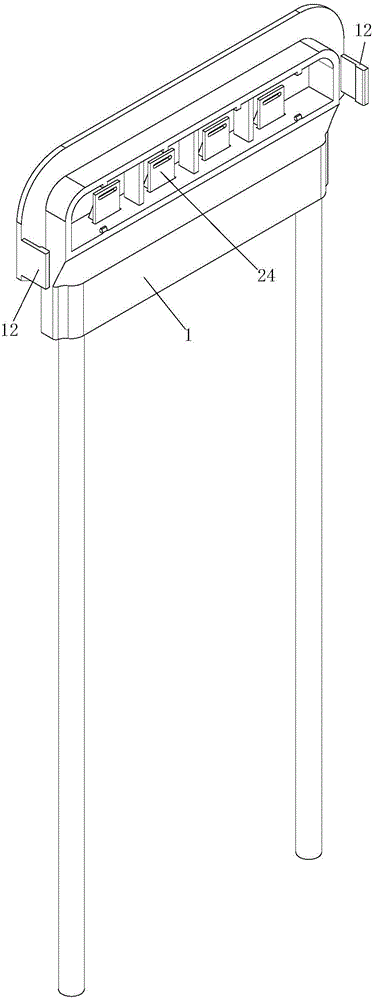

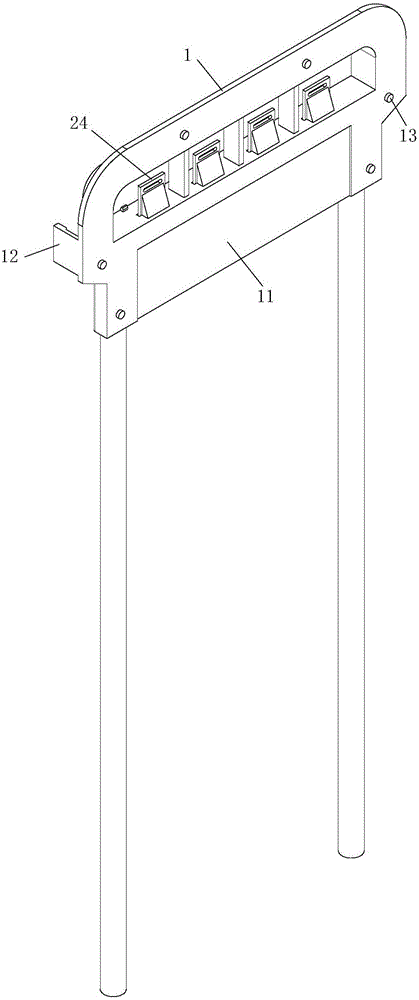

[0031] Reference attached figure 1 to attach Figure 4 , a low-junction temperature photovoltaic junction box, which includes a chip module 2, and a shell 1 wrapped outside the chip module 2.

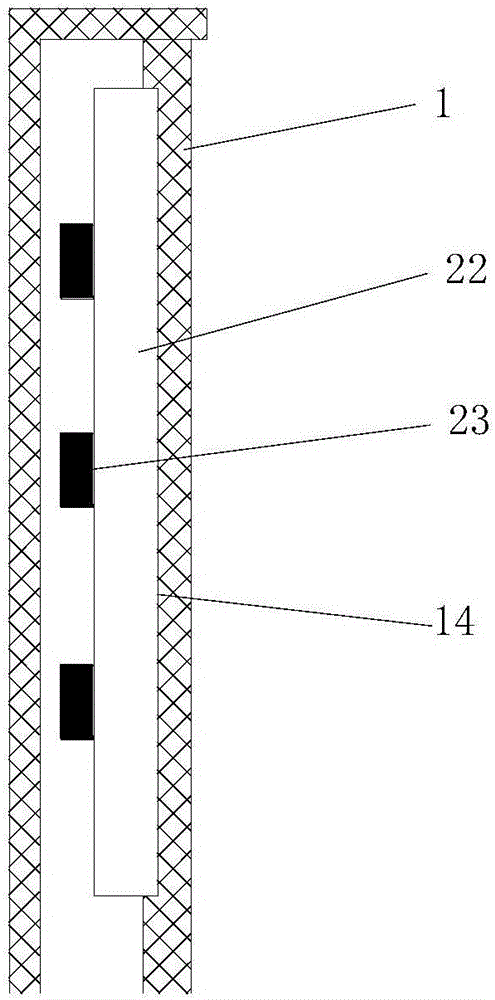

[0032] The chip module 2 includes a chip assembly, the chip assembly has a circuit surface with a circuit, and a heat dissipation surface opposite to the circuit surface, and the heat dissipation surface is in direct contact with the above-mentioned housing 1 .

[0033] The above-mentioned circuit face faces the back plate of the photovoltaic module connected with the casing. The photovoltaic module backplane can be a polymer backplane or a glass backplane.

[0034] There are many ways to connect the shell 1 and the chip assembly, such as attached image 3 In the present embodiment shown, a connection structure between the housing 1 and the chip assembly is provided: the inner side of the housing 1 has a groove 14, and the circuit surface of the chip assembly faces the groove 14 and ...

Embodiment 2

[0045] Reference attached Figure 5 The only difference between the low junction temperature photovoltaic junction box in this embodiment and the first embodiment is that in this embodiment, the housing 1 is integrally injection-molded on the chip module 2 and covers the chip module 2 .

[0046] In order to protect the circuit surface of the chip assembly from damage during the injection molding process of the housing 1 , the chip module 2 in this embodiment further includes a cover plate 21 connected with the chip assembly and covering the circuit surface of the chip assembly.

[0047] as attached Figure 5 As shown, the cover plate 21 covers the circuit surface of the chip assembly. One end of the terminal post 24 protrudes from the cover plate 21 . Reliability can be improved by dispensing epoxy glue between the cover plate 21 and the chip component (preferably at the diode). Due to the modular design of the chip, the chip module 2 can be directly embedded into the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com