A coffee bean cleaning and grading equipment

A technology for coffee beans and equipment is applied in the field of coffee bean cleaning and grading equipment, which can solve the problems of increased processing cost, high manufacturing cost, low secondary bean grading rate, etc., so as to ensure the quality of finished products, reduce processing procedures, and high secondary bean grading rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

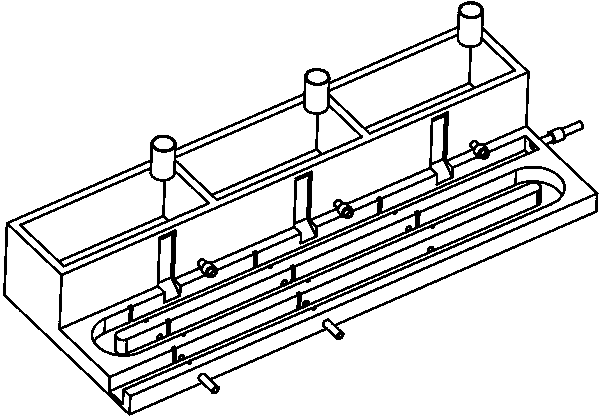

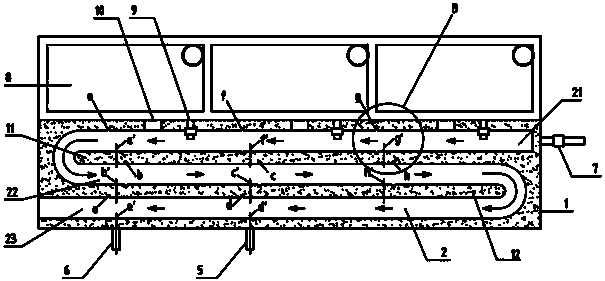

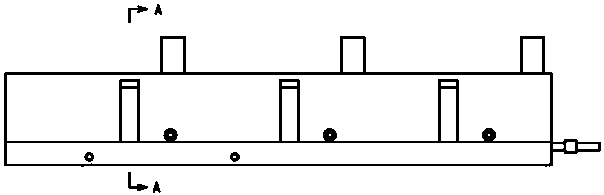

[0024] like Figure 1-Figure 5 As shown, a coffee bean cleaning and grading equipment includes infrastructure 1, S-type grading tank 2, primary discharge tank 5, secondary discharge tank 6, water inlet pipe 7, soaking tank 8 and feeding pipe 9, the The infrastructure 1 is fixedly installed, and a plurality of soaking pools 8 are arranged beside the infrastructure 1, and a feeding pipe 9 is arranged on each soaking pool 8, and an S-shaped grading tank 2 is arranged on the infrastructure 1, and the S-shaped grading tank 2 includes a Class classification tank 21, secondary classification tank 22 and three-level classification tank 23, separated by the first barrier layer 11 between the first-level classification tank 21 and the second-level classification tank 22, the second-level classification tank 22 and the third-level classification tank 33 by The second retaining layer 12 separates, the end of the primary classification tank 21 is connected to the beginning of the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com