Graphene-modified natural latex polymer and modification method thereof

A graphene modification and natural latex technology, applied in the field of natural rubber compositions, can solve problems such as uneven dispersion of graphene, and achieve the effects of improved mechanical properties, easy large-scale production, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

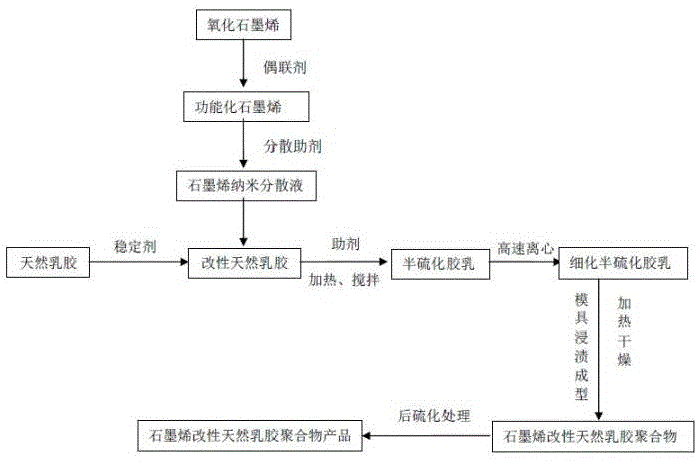

[0046] Graphene modified natural latex polymer modification method of the present invention, comprises the steps:

[0047] 1) First, dissolve graphene oxide and a coupling agent with a mass percentage of 50% in absolute ethanol under continuous stirring, then add graphene oxide to form a uniform dispersion, heat to 80°C, and continue to react for 15 hours , the obtained pasty product was first washed with absolute ethanol to remove excess unreacted coupling agent, and then washed with distilled water, and the undried pasty product was dispersed in distilled water, added hydrazine hydrate, and heated at 100°C Under the reduction reaction for 6h, the added mass of the hydrazine hydrate is 3 times of the added mass of the graphene oxide; then the product obtained is washed with excess absolute ethanol and distilled water, and the modified functionalized graphene is obtained after drying; the functionalized The size of graphene is 200-800nm, and the thickness is 1-3nm. The coupli...

Embodiment 2

[0063] Graphene modified natural latex polymer modification method of the present invention, comprises the steps:

[0064] 1) First, dissolve graphene oxide and a coupling agent with a mass percentage of 2% in absolute ethanol under continuous stirring, then add graphene oxide to form a uniform dispersion, heat to 60°C, and continue to react for 24 hours , the obtained paste product was first washed with absolute ethanol to remove excess unreacted coupling agent, and then washed with distilled water, and the undried paste product was dispersed in distilled water, added hydrazine hydrate, and heated at 80°C Under the reduction reaction for 4h, the added quality of the hydrazine hydrate is 0.5 times of the added quality of the graphene oxide; then the product obtained is washed with excess absolute ethanol and distilled water, and the modified functionalized graphene is obtained after drying; functionalized The size of graphene is 200-800nm, and the thickness is 1-3nm. The coup...

Embodiment 3

[0080] Graphene modified natural latex polymer modification method of the present invention, comprises the steps:

[0081]1) First, dissolve graphene oxide and a coupling agent with a mass percentage of 100% in absolute ethanol under continuous stirring, then add graphene oxide to form a uniform dispersion, heat to 70°C, and continue to react for 10 hours , the obtained paste product was first washed with absolute ethanol to remove excess unreacted coupling agent, and then washed with distilled water, and the undried paste product was dispersed in distilled water, added hydrazine hydrate, and heated at 85°C Under the reduction reaction for 5h, the added quality of the hydrazine hydrate is 5 times of the added quality of the graphene oxide; then the product obtained is washed with excess absolute ethanol and distilled water, and the modified functionalized graphene is obtained after drying; functionalized The size of graphene is 200-800nm, and the thickness is 1-3nm. The coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com