High-temperature rotation heating device for bolt surface processing

A surface treatment and rotary heating technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of polluting the working environment, endangering the health and safety of workers, and scattering of multi-alloy co-penetrant dust, etc. To achieve the effect of simple operation, guaranteeing health and safety, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

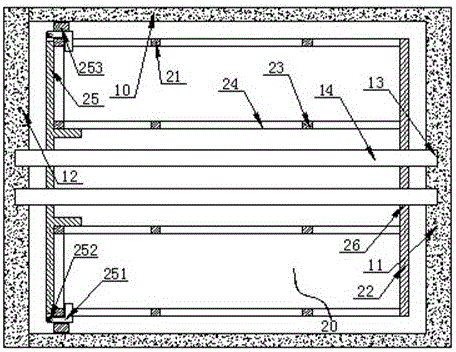

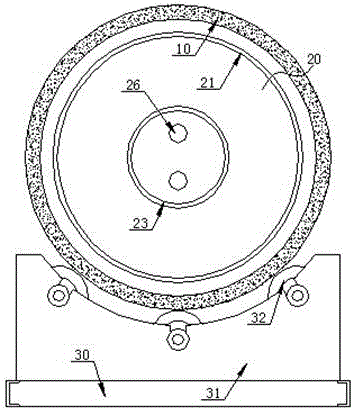

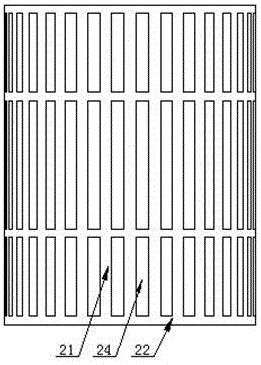

[0020] refer to Figure 1 to Figure 4 , Figure 1 to Figure 4 It is a structural schematic diagram of a specific embodiment of the present invention.

[0021] Such as Figures 1 to 4 As shown, a high-temperature rotary heating device for bolt surface treatment includes a rotary heating tank 10, which is a closed cylindrical structure and includes a heating tank bottom wall 11 and a heating tank cover 12; Car 30, the heating tank rotating car 30 is provided with a rotating support frame 31 along the axial ends of the rotating heating tank 10, and the top of the rotating support frame 31 is provided with several circular arc-shaped The two axial ends of the rotating heating tank 10 are placed on the support rollers 32 parallel to each other.

[0022] The rotary heating tank 10 is provided with a centralized processing cage 20, the centralized processing cage 20 includes a circular rolling outer wall 21 of a tubular structure, one axial end of the circular rolling outer wall 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com