Anti-abrasion device for casing pipe

An anti-wear, casing technology, applied in casing, drill pipe, drilling equipment, etc., can solve the problems of poor strength, easy to break and fall off, can not effectively improve the wear of the pipe string, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

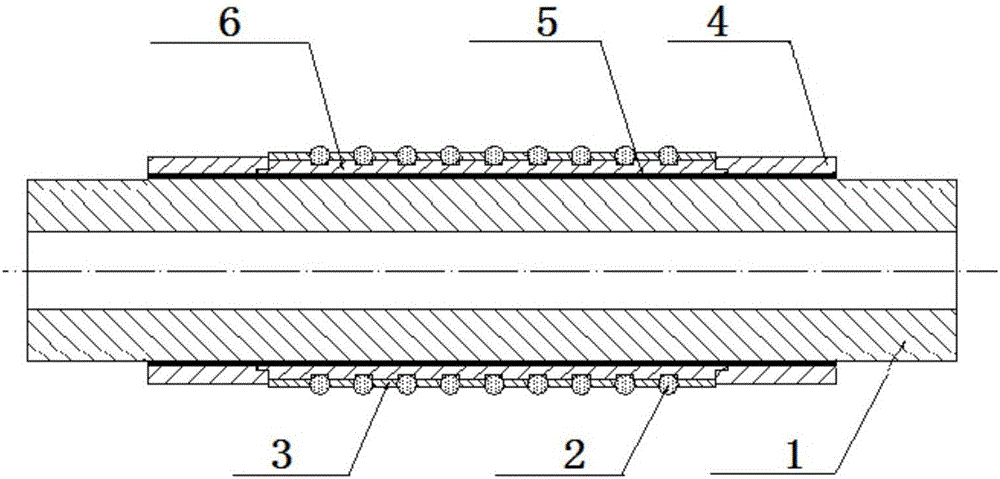

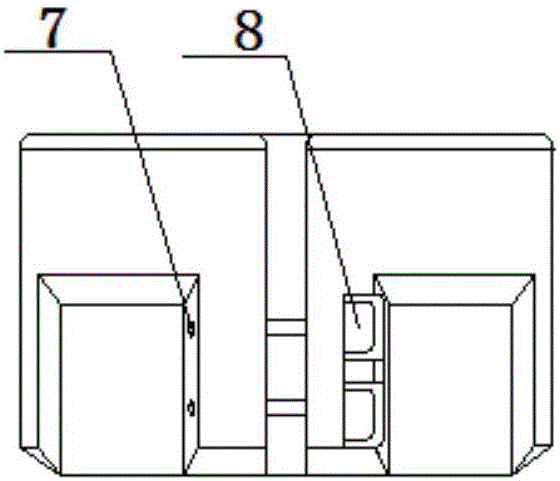

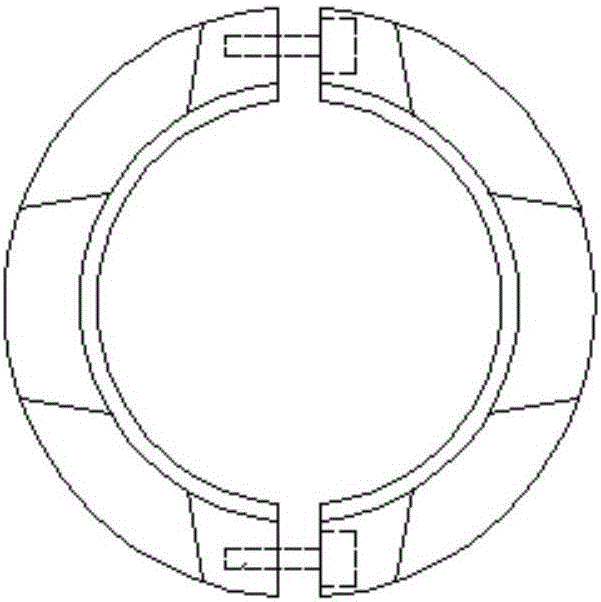

[0015] refer to figure 1 , figure 2 and image 3 , a bushing anti-wear device, including a ball seat 6, the ball seat 6 is a cylindrical structure, sleeved outside the pipe body 1, and the two ends of the ball seat 6 are respectively fixed to the pipe body 1 through a cylindrical fixed support 4 Above, the fixed support 4 is assembled with the screw 8 and the threaded hole 7 to realize the axial fixation of the protective sleeve. The inner wall of the ball seat 6 is provided with a rubber 5, and the outer wall is provided with a support frame 3 in the axial direction, and a number of annular depressions are arranged under the support frame 3, and a number of balls 2 are arranged on the support frame 3, and each ball 2 is correspondingly located in a ring. Above the recessed part, and each ball 2 protrudes outside the outer wall of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com