Carbon fiber supplement light device for greenhouse and preparation method thereof

A carbon fiber, supplementary light technology, which is applied in botanical equipment and methods, lighting devices, gardening methods, etc. The effect of needing, optimizing the way energy is used and distributed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

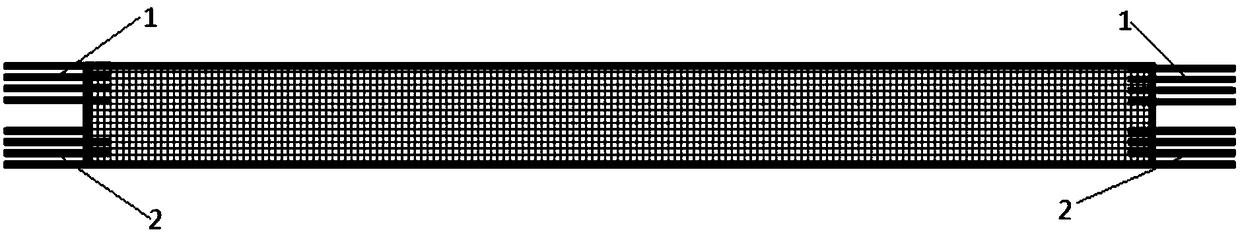

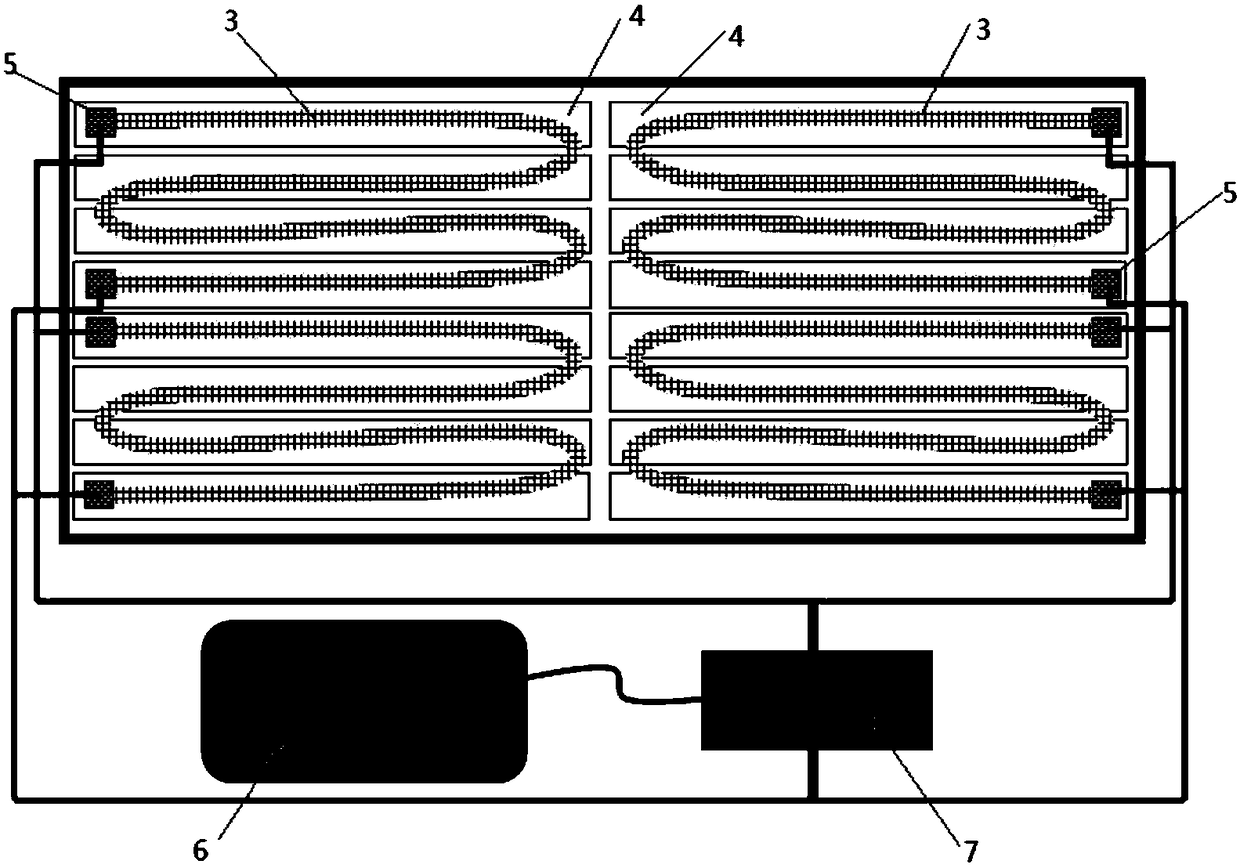

[0031] (1) Preparation of carbon fiber hybrid braid light source. Use 6 strands of 1K specification T300 carbon fiber and 16 strands of 10K tungsten fiber filaments with a single diameter of 5 microns to mix, weave a braid with a thickness of 0.2mm and a width of 10mm in a rectangular section. The braid of the light source can be cut, bent or Coiled, to a continuous length.

[0032] (2) The shed layout and electrical connector design of the braided light source. A semi-cylindrical fill light reflector made of stainless steel is selected, and the reflectivity of the reflector is not less than 0.9. Arrange S-shaped braided belt light source outside the reflector, and the covered area of the braided belt is 50% of the total area of the top and side walls of the vegetable greenhouse. The terminals of the braided strands are connected in parallel, and the spring pressing structure is used at the terminals to ensure low contact resistance and connection tightness of the termin...

Embodiment 2

[0036] (1) Preparation of carbon fiber hybrid braid light source. Use 7 strands of 3K specification T700 carbon fiber and 12 strands of 12K molybdenum fiber filaments with a single diameter of 8 microns to mix, weave a braid with a thickness of 0.7mm and a width of 12mm in a rectangular section. The braid of the light source can be cut, bent or Coiled, to a continuous length.

[0037] (2) The shed layout and electrical connector design of the braided light source. The hemispherical fill light reflector made of aluminum alloy is selected, and the reflectivity of the reflector is not lower than 0.9. A circular braided light source is arranged outside the reflector, and the covered area of the braided tape is 50% of the total area of the top and side walls of the vegetable greenhouse. The terminals of the braided strands are connected in parallel, and the spring pressing structure is used at the terminals to ensure low contact resistance and connection tightness of the term...

Embodiment 3

[0041] (1) Preparation of carbon fiber hybrid braid light source. 8 strands of 6K specification T800 carbon fiber are mixed with 18 strands of 10K stainless steel superfine fiber with a single filament diameter of 10 microns to weave a braid with a thickness of 0.9mm and a width of 15mm in a rectangular section. The braid of the light source can be cut and bent at will Or coiled, for continuous length.

[0042] (2) The shed layout and electrical connector design of the braided light source. The overall flat fill light reflector made of stainless steel is selected, and the reflectivity of the reflector is not less than 0.9. Arrange an S-shaped braided belt light source outside the reflector, and the covered area of the braided belt is 40% of the total area of the top and side walls of the vegetable greenhouse. The terminals of the braided strands are connected in parallel, and the spring pressing structure is used at the terminals to ensure low contact resistance and conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com