Application for nitrogen-doped graphene used as catalyst in removal of SO2 through electrooxidation method

A nitrogen-doped graphene, electro-oxidation technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of complex preparation process, high cost of electro-oxidation catalysts, poor catalytic activity, etc., to achieve Simple preparation process, excellent electrochemical catalytic activity, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

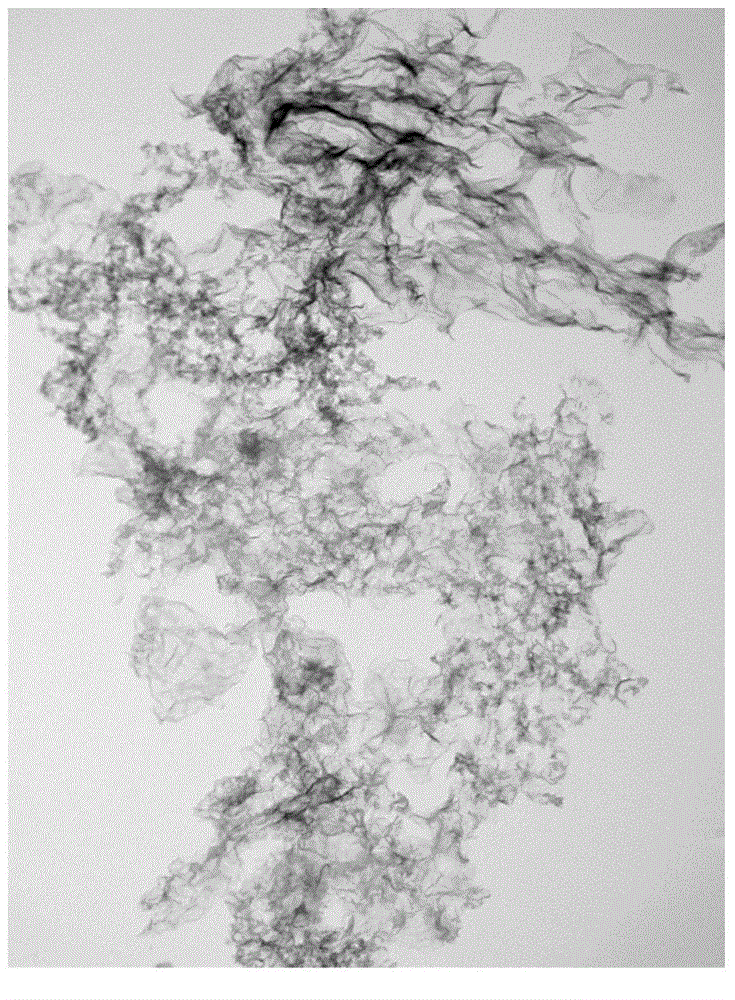

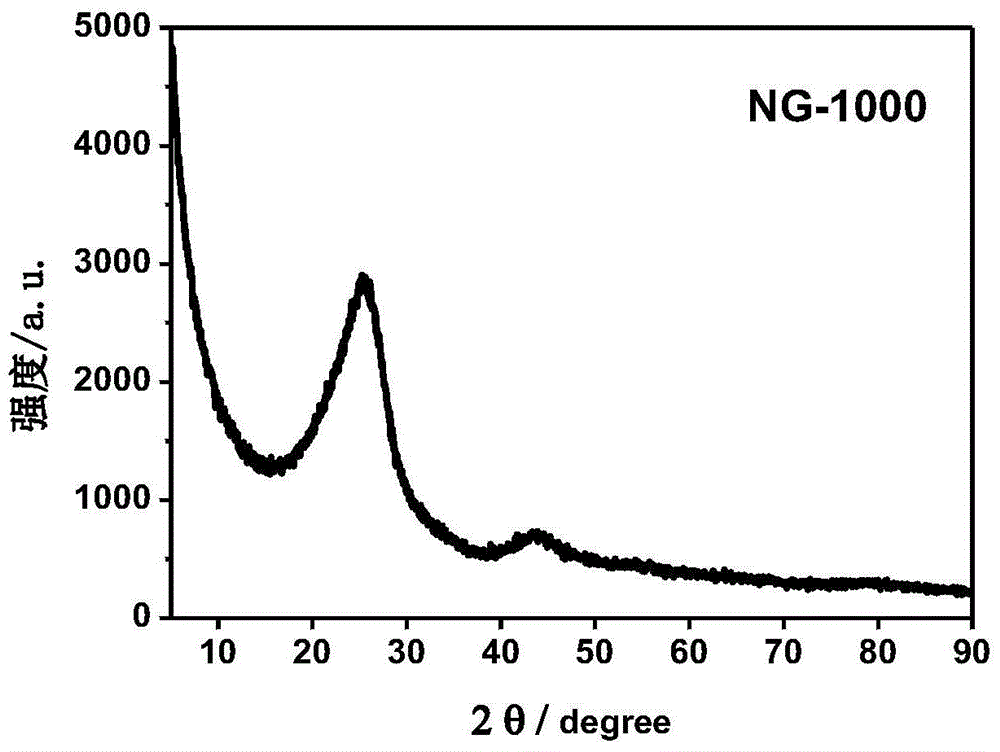

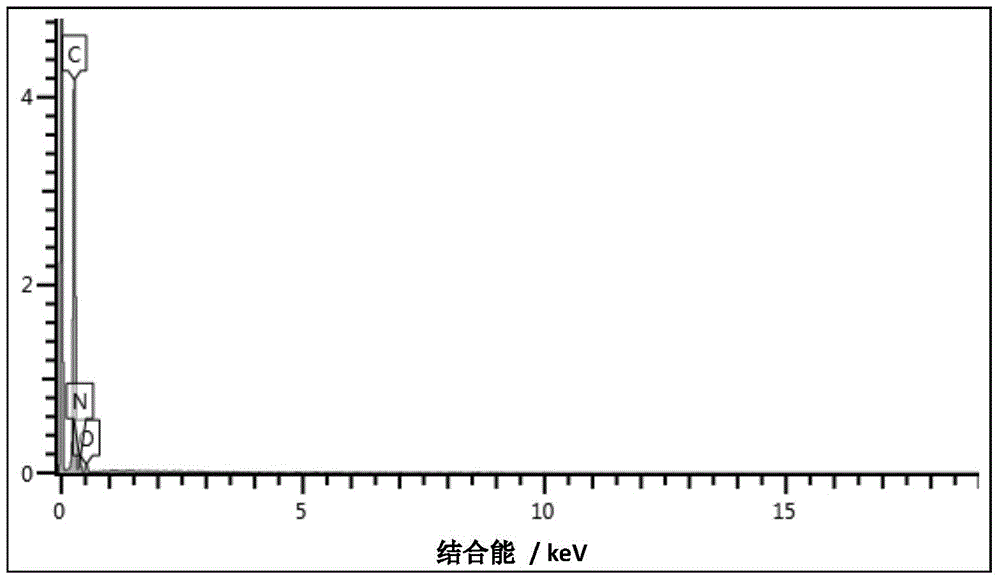

[0044] Weigh 0.1 g of sucrose and 6 g of urea and dissolve in 7 g of deionized water, and stir until completely dissolved. Heat and dry at 60°C on a hot table to obtain a white solid, and continue heating at 60°C until the white solid is completely dry. Transfer the white solid to a quartz boat, put it in a tube furnace, heat it from room temperature to 1000°C at a heating rate of 4°C / min, bake it at 1000°C for 1h, and continuously pass it into Ar for protection. The Ar flow rate is 200sccm, and the final preparation The obtained nitrogen-doped graphene (NG-1000). from TEM figure 1 It can be seen that nitrogen-doped graphene NG-1000 is a thin layer structure, figure 2 At 2θ=25°, there are obvious graphite characteristic peaks, image 3 EDS spectrum shows the existence of N element.

[0045] Weigh 2 mg of nitrogen-doped graphene NG-1000, 1 mL of isopropanol, and 50 μL of 5% Nafion solution in a 10 mL sample bottle, and disperse evenly by ultrasonication for 30 minutes to pre...

Embodiment 2

[0047] The experiment was carried out with the same method as in Example 1, except that the high-temperature calcination temperature was 800°C. from Figure 5 It can be seen that the prepared nitrogen-doped graphene NG-800 has a thin layer structure. Image 6 It shows that there are obvious graphite characteristic peaks at 2θ=25°, Figure 7 shows the presence of C and N elements. use it as SO 2 When electrooxidizing the catalyst, from Figure 8 It can be seen from the cyclic voltammetry curve that the nitrogen-doped graphene NG-800 on SO 2 It has electro-oxidation catalytic activity, and the oxidation current peak appears around 1.2V (vs. SHE).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com