Plutonium purification cycle process using formaldoxime as back extraction reagent

The technology of stripping reagent and formaldehyde oxime is applied in the field of plutonium purification and circulation process, which can solve the problems of low concentration level and poor safety, and achieve the effects of reducing the amount of use, high plutonium yield and improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

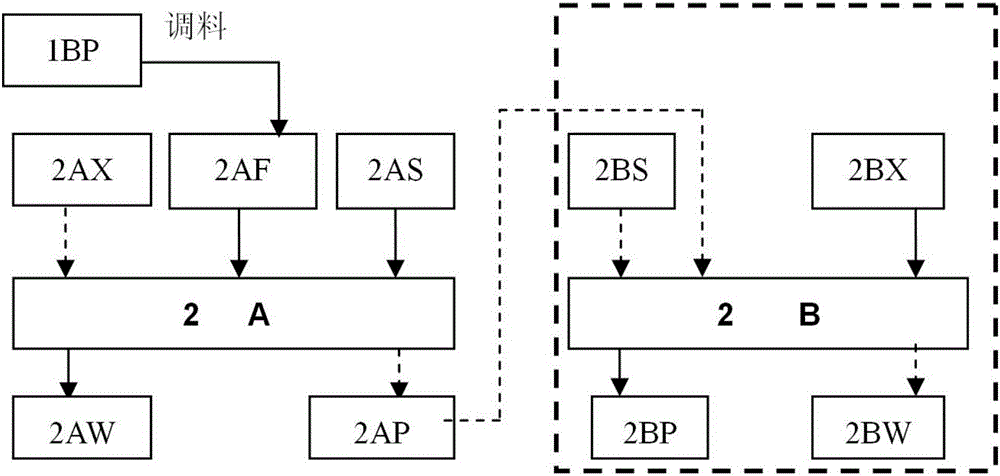

[0020] Applying the plutonium purification cycle process of the present invention to the purification and concentration of plutonium products in the Purex process, the following process conditions are adopted:

[0021] (1) The formaldehyde oxime concentration of 2BX is 0.6mol / L, and the nitric acid concentration is 0.4mol / L;

[0022] (2) The plutonium nitrate concentration of 2BF is 12g / L, the nitric acid concentration is 0.2mol / L, and the uranium concentration is 0.76g / L;

[0023] (3) The nitric acid concentration of 2BS is 0.2mol / L;

[0024] (4) flow ratio 2BF:2BX=5:1;

[0025] (5) There are 11 stages of back-extraction and 5 stages of re-extraction.

[0026] The plutonium concentration of the obtained plutonium product liquid is 60.3g / L, the residual plutonium concentration in the organic phase is about 0.4mg / L, the plutonium yield is greater than 99.99%, and the separation factor SF for removing uranium from plutonium is U / Pu >10 4 .

Embodiment 2

[0028] Applying the plutonium purification cycle process of the present invention to the purification and concentration of plutonium products in the Purex process, the following process conditions are adopted:

[0029] (1) The formaldehyde oxime concentration of 2BX is 0.5mol / L, and the nitric acid concentration is 0.5mol / L;

[0030] (2) The plutonium nitrate concentration of 2BF is 15g / L, the nitric acid concentration is 0.15mol / L, and the uranium concentration is 1.86g / L;

[0031] (3) The nitric acid concentration of 2BS is 0.3mol / L;

[0032] (4) flow ratio 2BF:2BX=3:1;

[0033] (5) There are 12 stages of back extraction and 3 stages of re-extraction.

[0034] The plutonium concentration of the obtained plutonium product liquid is 54.8g / L, the residual plutonium concentration in the organic phase is about 0.5mg / L, the plutonium yield is greater than 99.99%, and the separation factor SF for removing uranium from plutonium is U / Pu >3000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com