Ground wire overhead vehicle special for large span

A technology of large span and ground wire, applied in the direction of overhead line/cable equipment, etc., can solve the problem of inability to complete the installation task, and achieve the effect of ensuring normal traffic, saving construction time and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with specific embodiments in conjunction with the accompanying drawings

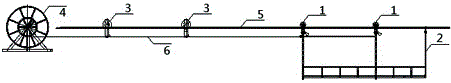

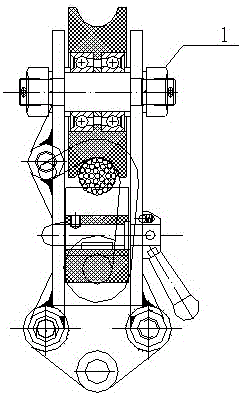

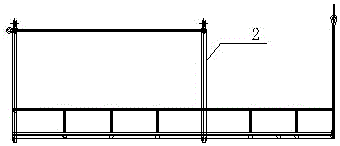

[0017] Such as figure 1 Shown: The special ground speed car for large spans is composed of a load-bearing block 1, a working platform 2, a line block 3, a rope-holding device 4, a ground line 5 and a traction rope 6. The working platform 2 is installed on the right side, and the rope-holding block The device 4 is installed on the left side. Two groups of load-bearing tackles 1 are installed on the working platform 2. The working platform 2 is connected with the rope-holding device 4 through the traction rope 6. Two sets of hanging tackle 3 are installed above the traction rope 6 above the working platform 2. A ground wire 5 is installed, and the ground wire 5 runs through two groups of load-bearing tackles 1, two groups of hanging tackles 3, and its ground wire 5 and traction rope 6 are parallel to each other.

[0018] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com