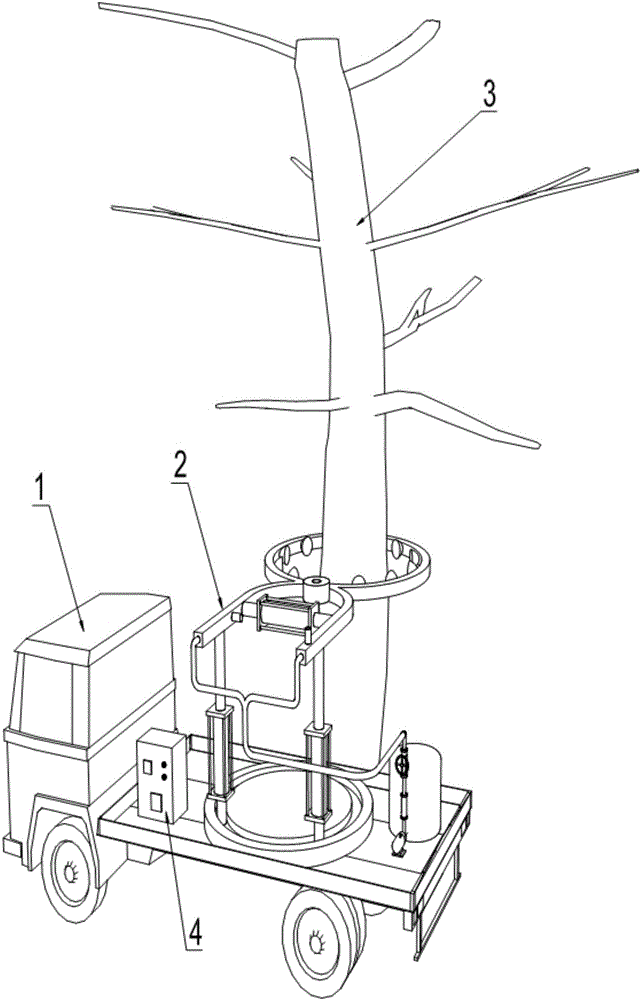

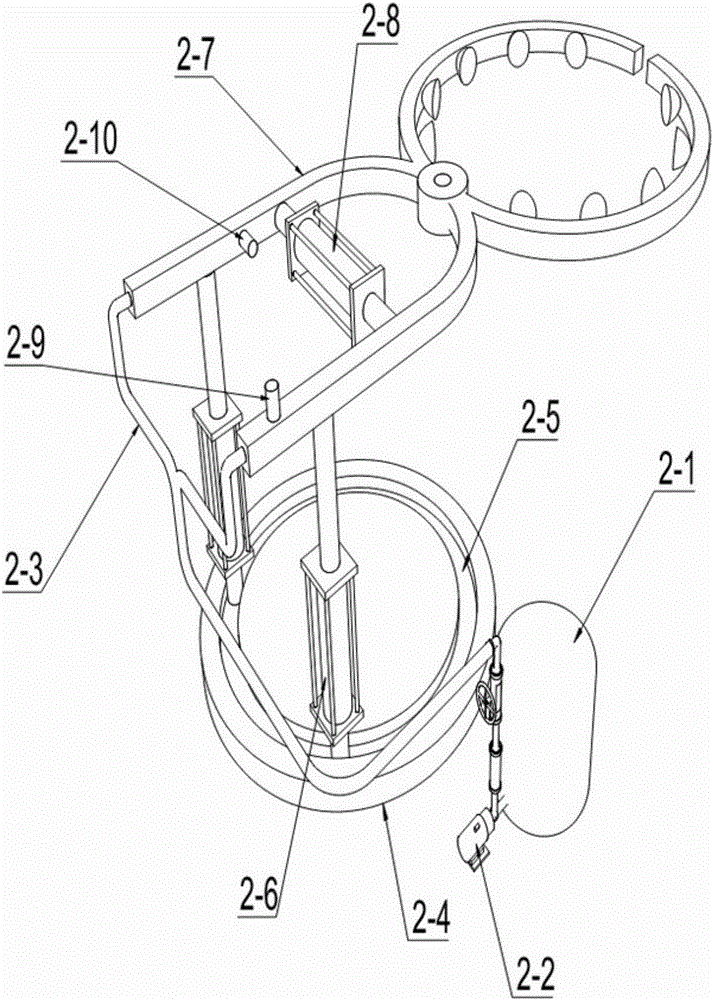

Vehicle-mounted diagnosis and treatment equipment for endangered plant Cercidiphyllum japonicum and working method of vehicle-mounted diagnosis and treatment equipment

A treatment equipment and vehicle-mounted technology, which is applied to the field of vehicle-mounted diagnostic and treatment equipment for the endangered plant Lianxiangshu, can solve the problems of health hazards for brushers, poor application efficiency, time-consuming and labor-intensive, etc., and achieves efficient diagnosis and treatment efficiency and a degree of automation. High, easy to control and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

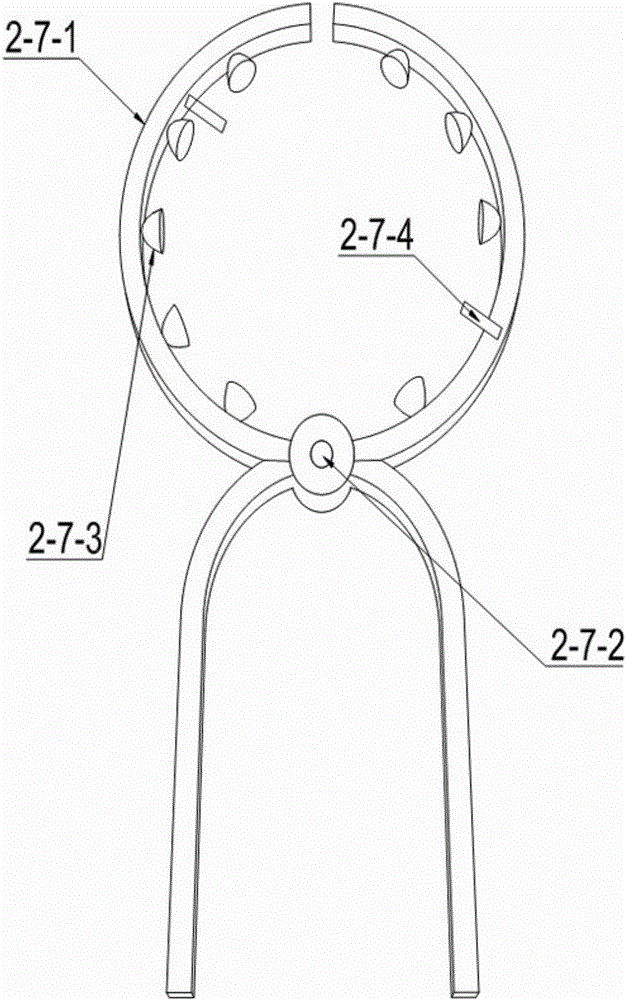

[0049] Manufacture the spray agent regulating frame 2-7-1 of the present invention according to the following steps, and by weight fraction:

[0050] Step 1: Add 351 parts of ultrapure water with a conductivity of 1.1μS / cm into the reactor, start the stirrer in the reactor at a speed of 101rpm, start the heating pump to raise the temperature in the reactor to 31°C; add in sequence 31 parts of ethylene propylene fumarate, 21 parts of ethyl (methyldiethoxysilyl) maleate, 51 parts of dibutyltin maleate, stir until completely dissolved, and adjust the pH value to 3.1, the stirrer speed was adjusted to 141rpm, the temperature was 71°C, and the esterification reaction was carried out for 11 hours;

[0051] Step 2: Take 131 parts of maleic-1,4-diol dibutyrate and 111 parts of hydroxypropylmethylcellulose acetate maleate to pulverize, the particle size of the powder is 111 mesh; add acrylic acid Mix 31 parts of hydroxyethyl ester hydroxychloropropyl maleate evenly, spread it on the tra...

Embodiment 2

[0056] Manufacture the spray agent regulating frame 2-7-1 of the present invention according to the following steps, and by weight fraction:

[0057] Step 1: Add 1151 parts of ultrapure water with a conductivity of 2.1μS / cm into the reactor, start the stirrer in the reactor at a speed of 211rpm, start the heating pump, and increase the temperature in the reactor to 51°C; add in sequence 91 parts of ethylene propylene fumarate, 71 parts of ethyl (methyldiethoxysilyl) maleate, 91 parts of dibutyltin maleate, stir until completely dissolved, and adjust the pH to 9.1, the agitator speed was adjusted to 211rpm, the temperature was 141°C, and the esterification reaction was carried out for 21 hours;

[0058] Step 2: Take 261 parts of maleic-1,4-diol dibutyrate and 271 parts of hydroxypropylmethyl cellulose acetate maleate for pulverization, the particle size of the powder is 321 mesh; add acrylic acid Mix 101 parts of hydroxyethyl ester hydroxychloropropyl maleate evenly, spread it...

Embodiment 3

[0063] Manufacture the spray agent regulating frame 2-7-1 of the present invention according to the following steps, and by weight fraction:

[0064] Step 1: Add 950 parts of ultrapure water with a conductivity of 1.5μS / cm into the reactor, start the stirrer in the reactor at a speed of 171rpm, start the heating pump, and raise the temperature in the reactor to 41°C; add in order 61 parts of ethylene propylene fumarate, 41 parts of ethyl (methyldiethoxysilyl) maleate, 61 parts of dibutyltin maleate, stir until completely dissolved, and adjust the pH to 5.1, the agitator speed was adjusted to 181rpm, the temperature was 111°C, and the esterification reaction was carried out for 16 hours;

[0065] Step 2: Take 161 parts of maleic-1,4-diol dibutyrate and 171 parts of hydroxypropylmethyl cellulose acetate maleate for pulverization, the particle size of the powder is 221 mesh; add acrylic acid Mix 81 parts of hydroxyethyl ester hydroxychloropropyl maleate evenly, spread it in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com