Wet type electric defogging device

A demisting device, wet electricity technology, applied in the direction of electrostatic separation, external electrostatic separator, etc., can solve the problems of high equipment operation and maintenance costs, inability to effectively remove dust particles, air leakage, etc., and achieve less waste parts, easy maintenance and operation low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the drawings. It should be noted that the drawings are only used to explain the present invention, and are schematic descriptions of the embodiments of the present invention, and should not be construed as limiting the present invention.

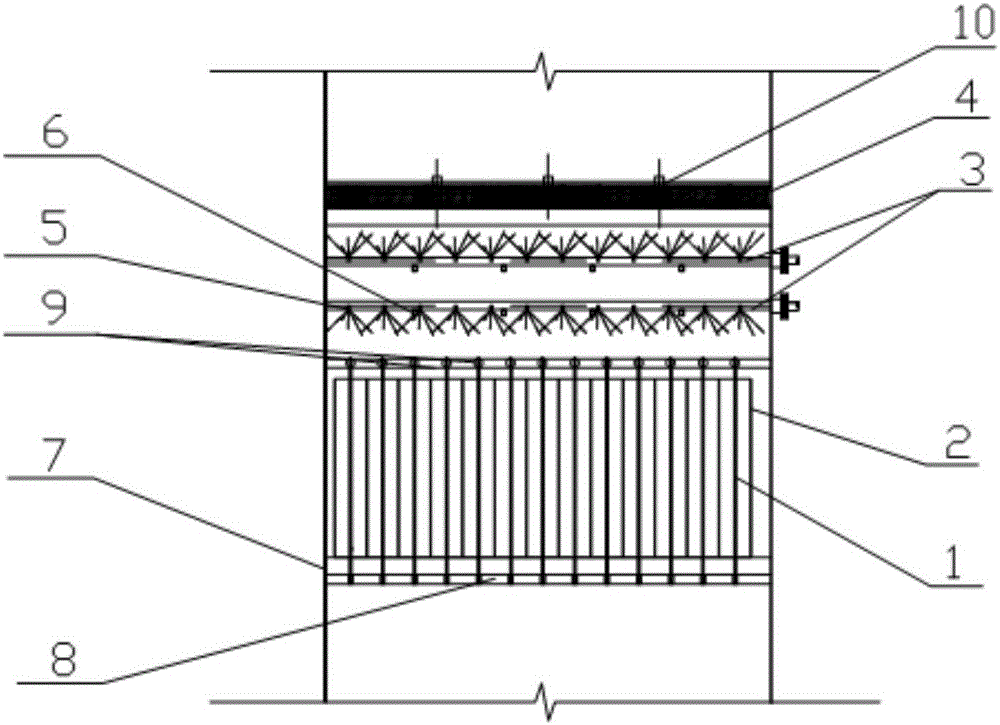

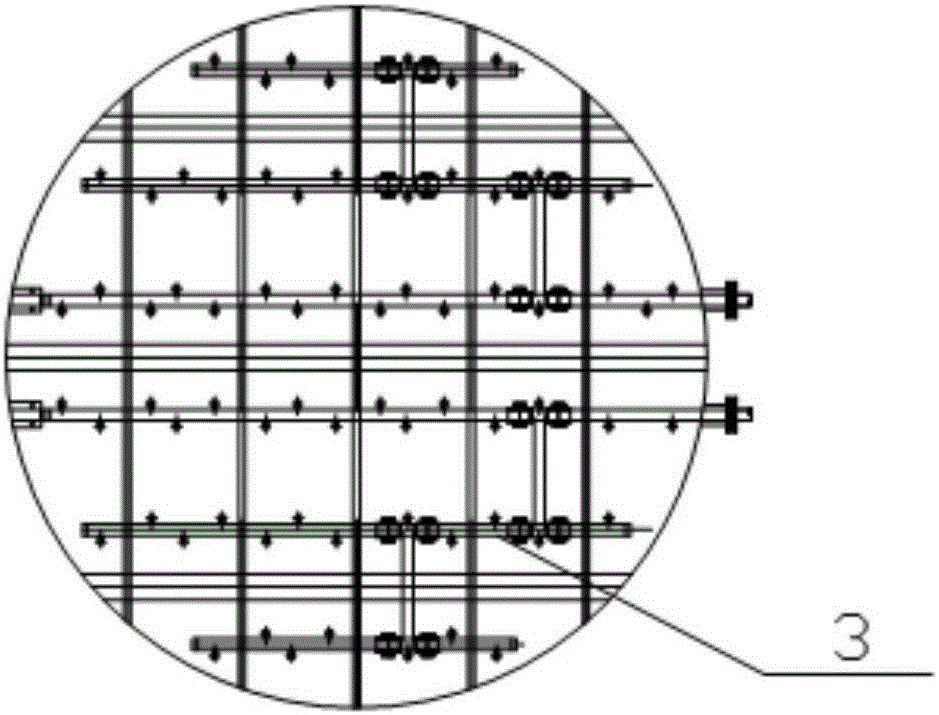

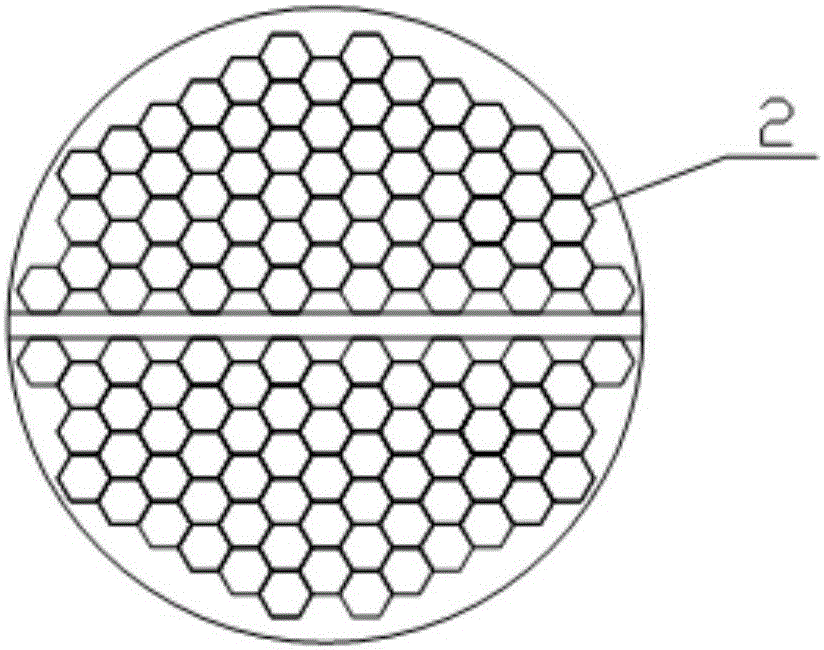

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the wet electrostatic defogging device is composed of cathode line 1, anode tube 2, backwash water pipe 3, defogging layer 4, nozzle 5, water pipe support beam 6, tower body 7, anode bracket 8, and large and small beams 9 Composed of support beams 10, the tower body 7 is equipped with water pipe support beams 6, anode racks 8, and large and small beams 9, the anode rack 8 is provided with anode tubes 2, the cathode line 1 is hoisted on the large and small beams 9, and the defogging layer 4 Tiled on the supporting beam 10, the backwashing water pipe 3 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com