Electrochemical preparation method of phenylamine-4-aminosalicylic acid copolymer

A technology of aminosalicylic acid and copolymer, which is applied in electrolysis process, electrolysis components, electrolysis organic production, etc. It can solve the problems of reduced application potential range, limitation of electrochemical properties, loss of electrochemical activity, etc., and achieves wide application prospects , Wide application potential range, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of aniline-4-aminosalicylic acid copolymer:

[0018] (1) Preparation of electrolyte: preparation of 0.20mol dm -3 Aniline, 2.0mol·dm -3 Sulfuric acid and 0.02mol·dm -3 A mixed solution of 4-aminosalicylic acid.

[0019] (2) The configuration of the electrolytic cell: a three-electrode system is adopted, a bare glassy carbon electrode is used as the working electrode, a platinum sheet electrode with an area of 1cm×2cm is used as the auxiliary electrode, and a saturated calomel electrode is used as the reference electrode.

[0020] (3) Pretreatment of the working electrode: the glassy carbon electrode was polished with 0.3 μm alumina powder, cleaned with ultrapure water, and then moved into an ultrasonic water bath for cleaning for 10 minutes.

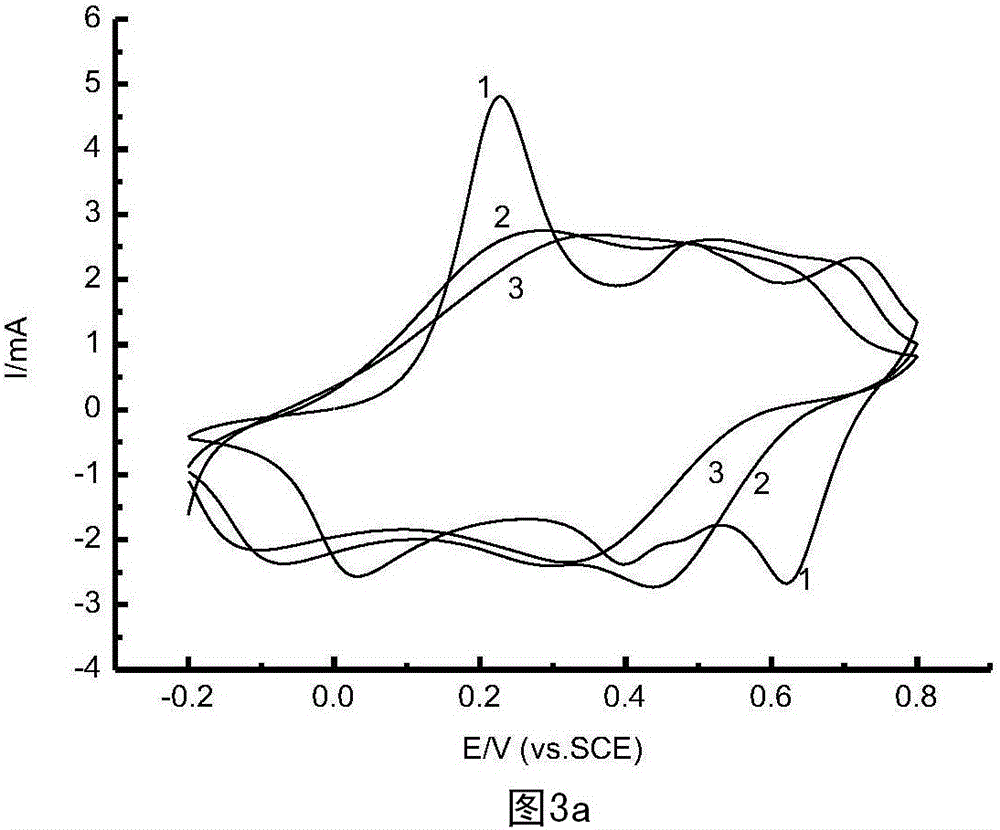

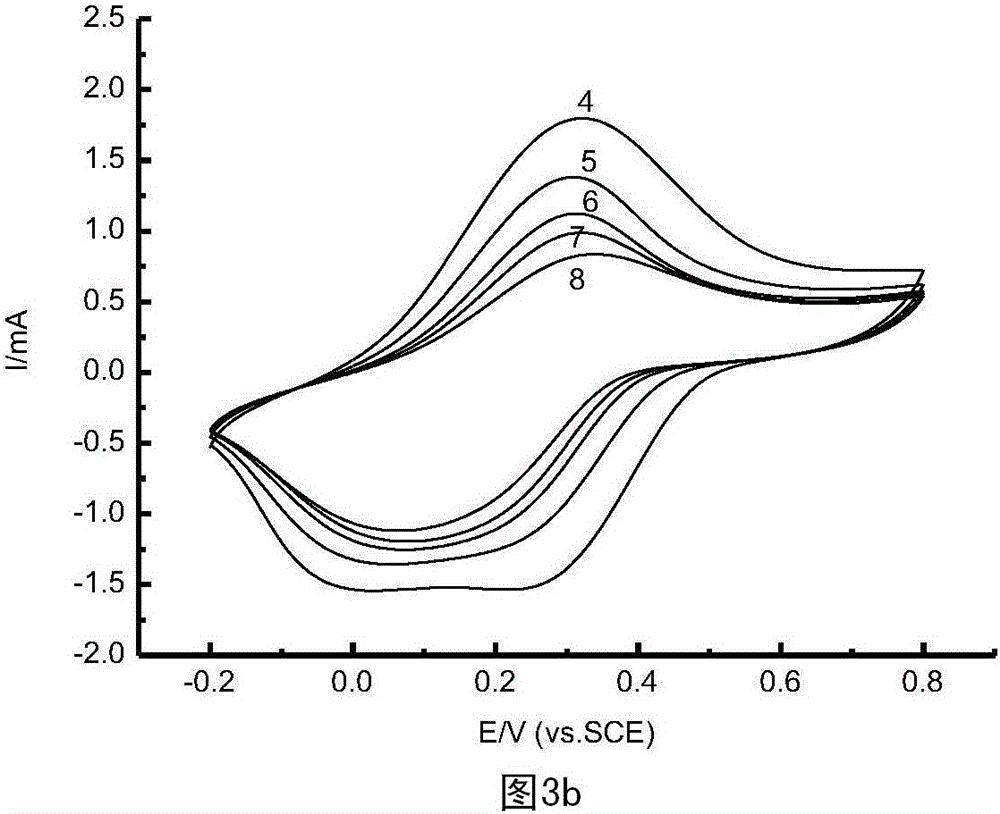

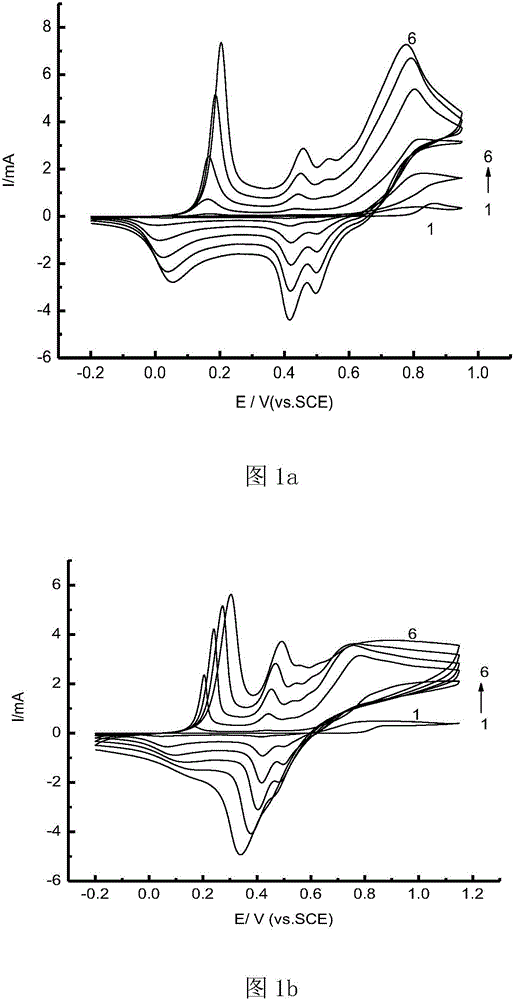

[0021] (4) Electrochemical preparation of the copolymer: the prepared electrolyte solution was added to a three-electrode electrolytic cell, and the copolymer was synthesized on the glassy carbon electrode by cycl...

Embodiment 2

[0025] The difference from Example 1 is that the scanning potential range is -0.2~1.15V. After comparison, it can be seen that the copolymer is synthesized better than Example 1 at -0.2~1.15V when the scanning potential range is -0.2~0.95V. and easier to generate.

Embodiment 3

[0027] Basically the same as Example 1, the difference is: the "2.0mol dm in Example 1 -3 Sulfuric acid" was changed to "1.5mol dm -3 Sulfuric acid ", result is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com