Tensile strength-780 MPa-stage vanadium-contained cold-rolled dual-phase steel and preparation method thereof

A technology of tensile strength and dual-phase steel, which is applied in the field of high-strength steel and its preparation, can solve the problems of production cost, formability and welding performance without comprehensive consideration, and achieve the effect of reducing production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

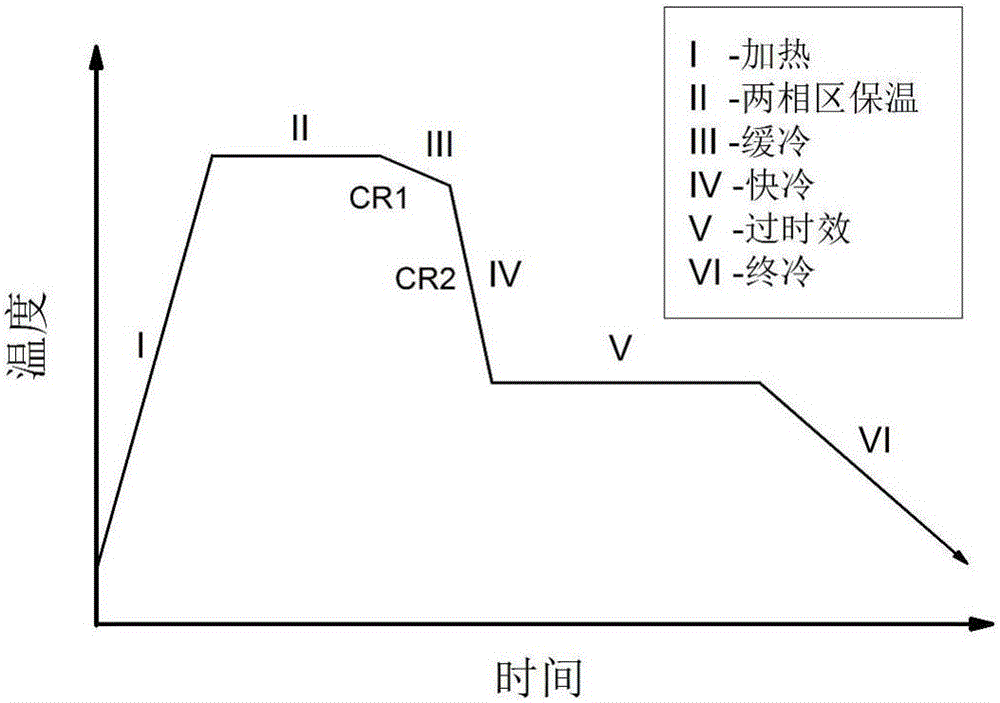

[0036] The preparation method of the above-mentioned vanadium-containing cold-rolled dual-phase steel with a tensile strength of 780MPa comprises the following steps:

[0037] a. Smelting process: smelting according to the weight percentage composition of the above-mentioned vanadium-containing cold-rolled dual-phase steel with a tensile strength of 780MPa, and controlling its vanadium content in the converter (by controlling the vanadium content in the original molten iron, rather than adding additional vanadium ferroalloy), cast into a slab to obtain a slab;

[0038] b. Hot rolling process: the billet is heated, dephosphorized, hot-rolled and laminar cooling to obtain hot-rolled coils; the starting temperature of the finish rolling is 1000-1100 ° C, the final rolling temperature is 850-950 ° C, and the coiling The temperature is 600~700℃;

[0039] c. Pickling process: hot-rolled coils are subjected to pickling (i.e. pickling + cold rolling process) to obtain thin strip stee...

Embodiment 1

[0047] The preparation method of the 780MPa grade vanadium-containing cold-rolled dual-phase steel provided by the present invention has the following processes:

[0048] (1) Through the smelting process, a dual-phase steel slab with the chemical composition shown in Table 1 is prepared:

[0049] Table 1 Chemical Composition of Duplex Steel (wt.%)

[0050] Numbering

C

Si

mn

P

S

als

Cr

V

N

DP1

0.11

0.52

1.70

0.012

0.008

0.040

0.35

0.06

0.004

DP2

0.12

0.40

1.60

0.012

0.006

0.030

0.40

0.05

0.005

[0051] (2) After heating, dephosphorization, hot rolling and laminar cooling to obtain hot rolled coils, the starting temperature of finish rolling is 1000-1100°C, the finishing rolling temperature is 850-950°C, and the coiling temperature is 600°C ~700°C; the specific hot rolling process parameters are shown in Table 2 below:

[0052] Table 2 Main process parameters of ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com