Wet crock fastness improver and preparation method thereof

A technology of wet rubbing fastness and improving agent, which is applied in the field of wet rubbing fastness improving agent and its preparation, which can solve the problems of dye lifting, color fixing rate and low color fastness, and achieve good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

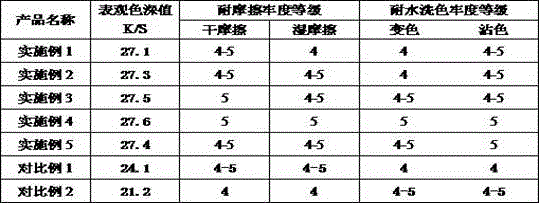

Examples

Embodiment 1

[0022] A wet rubbing fastness improving agent is prepared from the following ingredients in parts by weight: 5 parts of epoxy soybean oil, 20 parts of castor oil, 1 part of sorbitol, 2 parts of trimethylolpropane, N,N-dimethyl 5 parts of methyl formamide, 2 parts of isophorone diisocyanate, 1 part of cetylpyridinium bromide, 1 part of alkyl dimethyl ammonium chloride, 1 part of sodium bisulfate, 0.2 part of dibutyltin dilaurate , 0.2 parts of dibutyltin diacetate, 2 parts of polyvinyl alcohol, 2 parts of triethylamine, 5 parts of acetone, and 10 parts of distilled water.

[0023] The preparation method of the above-mentioned wet rubbing fastness improving agent is as follows: (1) mix epoxidized soybean oil and castor oil, and vacuum-dry at 100° C. for 2 hours; (2) mix with isophorone diisocyanate, cetyl bromide Mix alkylpyridine and alkyldimethylammonium chloride, add it to a four-necked bottle, add dibutyltin dilaurate and dibutyltin diacetate while stirring, and react for 1 ...

Embodiment 2

[0025] A wet rubbing fastness improving agent is prepared from the following ingredients in parts by weight: 6 parts of epoxidized soybean oil, 22 parts of castor oil, 1.5 parts of sorbitol, 2.5 parts of trimethylolpropane, N,N-dimethyl 6 parts of methyl formamide, 2.5 parts of isophorone diisocyanate, 1.5 parts of cetylpyridinium bromide, 1.2 parts of alkyl dimethyl ammonium chloride, 1.3 parts of sodium bisulfate, 0.3 parts of dibutyltin dilaurate , 0.25 parts of dibutyltin diacetate, 2.5 parts of polyvinyl alcohol, 3 parts of triethylamine, 6 parts of acetone, and 12 parts of distilled water.

[0026] The preparation method of the above-mentioned wet rubbing fastness improving agent is as follows: (1) mix epoxidized soybean oil and castor oil, and vacuum-dry at 105° C. for 2.5 hours; (2) mix with isophorone diisocyanate, cetyl bromide Mix alkylpyridine and alkyldimethylammonium chloride, add it to a four-necked bottle, add dibutyltin dilaurate and dibutyltin diacetate while...

Embodiment 3

[0028] A wet rubbing fastness improving agent is prepared from the following ingredients in parts by weight: 7.5 parts of epoxidized soybean oil, 25 parts of castor oil, 2 parts of sorbitol, 3 parts of trimethylolpropane, N,N-dimethyl 7.5 parts of methyl formamide, 3 parts of isophorone diisocyanate, 2 parts of cetylpyridinium bromide, 1.5 parts of alkyl dimethyl ammonium chloride, 1.5 parts of sodium bisulfate, 0.35 parts of dibutyltin dilaurate , 0.3 parts of dibutyltin diacetate, 3 parts of polyvinyl alcohol, 3.5 parts of triethylamine, 7.5 parts of acetone, and 15 parts of distilled water.

[0029] The preparation method of the above-mentioned wet rubbing fastness improving agent is as follows: (1) mix epoxidized soybean oil and castor oil, and vacuum-dry at 105° C. for 2.5 hours; (2) mix with isophorone diisocyanate, cetyl bromide Alkyl pyridine and alkyl dimethyl ammonium chloride are mixed, added to a four-necked bottle, dibutyltin dilaurate and dibutyltin diacetate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com