Modification method of orange-peel pigment and application thereof in cotton-fabric dyeing

A technology of orange peel and pigment, which is applied in the modification of orange peel pigment and its application in cotton fabric dyeing. It can solve the problems of low fiber fabric binding, unstable pigment, easy to fade, etc., and achieve color fixation The effect is good, the economic value is improved, and the combination fastness is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

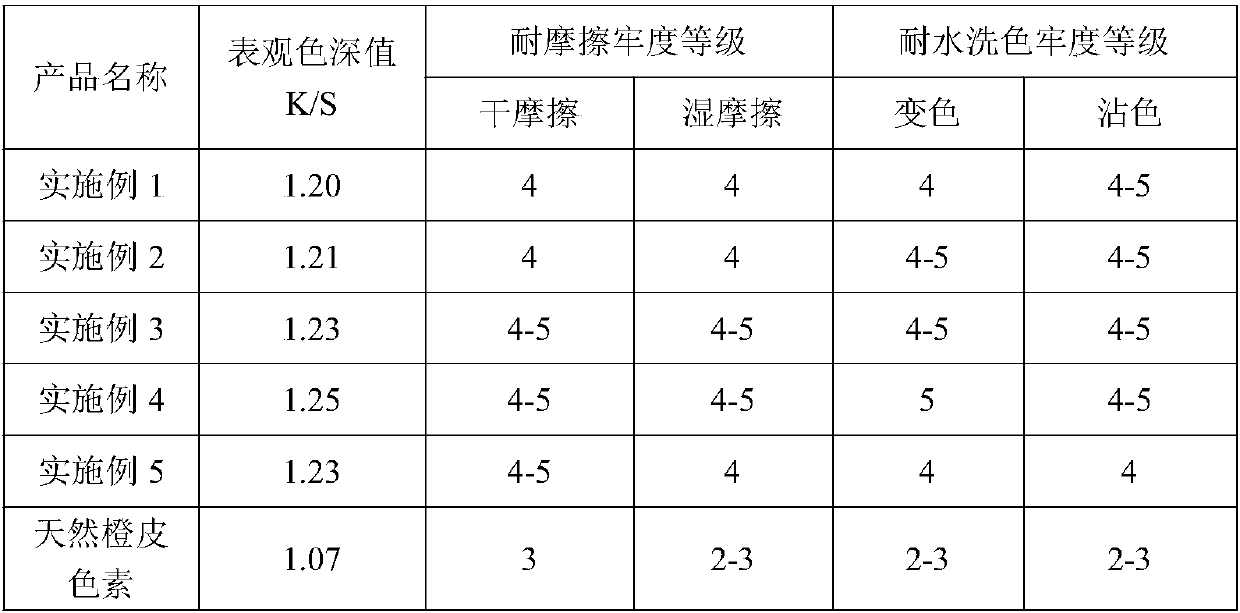

Examples

Embodiment 1

[0026] The modification method of orange peel pigment, composition is calculated by weight, comprises the following steps:

[0027] (1) Extraction of orange peel pigment: clean 10 parts of orange peel, dry and pulverize, add 200 parts of distilled water, boil in boiling water for 60 minutes, filter, and dry to obtain orange peel pigment;

[0028] (2) Mix 1 part of orange peel pigment, 1 part of mixed emulsifier and 20 parts of deionized water, place in a constant temperature water bath at 90°C, and stir for 30 minutes at a speed of 1000 rpm;

[0029] (3) transfer to colloid mill and process for 10min;

[0030] (4) Take it out, dry it, add 6 parts of 1-chlorododecane and stir evenly, add 0.5 part of anhydrous aluminum chloride, and oscillate in an air bath for 30 minutes;

[0031] (5) Cool to room temperature, add ice water and concentrated hydrochloric acid until completely dissolved, transfer to a separatory funnel and extract with ether twice, combine the layer solution whe...

Embodiment 2

[0036] The modification method of orange peel pigment, composition is calculated by weight, comprises the following steps:

[0037] (1) Extraction of orange peel pigment: clean 12 parts of orange peel, dry and pulverize, add 220 parts of distilled water, boil in boiling water for 65 minutes, filter, and dry to obtain orange peel pigment;

[0038] (2) Mix 1.2 parts of orange peel pigment, 1.3 parts of mixed emulsifier and 25 parts of deionized water, place in a constant temperature water bath at 90°C, and stir for 35 minutes at a speed of 1200 rpm;

[0039] (3) transfer to colloid mill and process for 15min;

[0040] (4) Take it out, dry it, add 7 parts of 1-chlorododecane and stir evenly, add 0.7 part of anhydrous aluminum chloride, and shake in an air bath for 35 minutes;

[0041] (5) Cool to room temperature, add ice water and concentrated hydrochloric acid until completely dissolved, transfer to a separatory funnel and extract with ether twice, combine the layer solution w...

Embodiment 3

[0046] The modification method of orange peel pigment, composition is calculated by weight, comprises the following steps:

[0047] (1) Extraction of orange peel pigment: clean 15 parts of orange peel, dry and pulverize, add 250 parts of distilled water, boil for 70 minutes with boiling water, filter, and dry to obtain orange peel pigment;

[0048] (2) Mix 1.5 parts of orange peel pigment, 1.5 parts of mixed emulsifier and 30 parts of deionized water, place in a constant temperature water bath at 90°C, and stir for 35 minutes at a speed of 1500 rpm;

[0049] (3) transfer to colloid mill and process for 15min;

[0050] (4) Take it out, dry it, add 8 parts of 1-chlorododecane and stir evenly, add 0.75 part of anhydrous aluminum chloride, and shake in an air bath for 40 minutes;

[0051] (5) Cool to room temperature, add ice water and concentrated hydrochloric acid until completely dissolved, transfer to a separatory funnel and extract with ether for 3 times, combine the layer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com