Asphalt recycling drying drum and drying method thereof

An asphalt recycling and roller technology, which is applied to roads, road repair, roads, etc., can solve the problems of asphalt aging, uneven and sufficient heating process of recycled materials, and low utilization rate of heat energy, etc., so as to reduce asphalt aging, protect the environment, and improve The effect of thermal regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments.

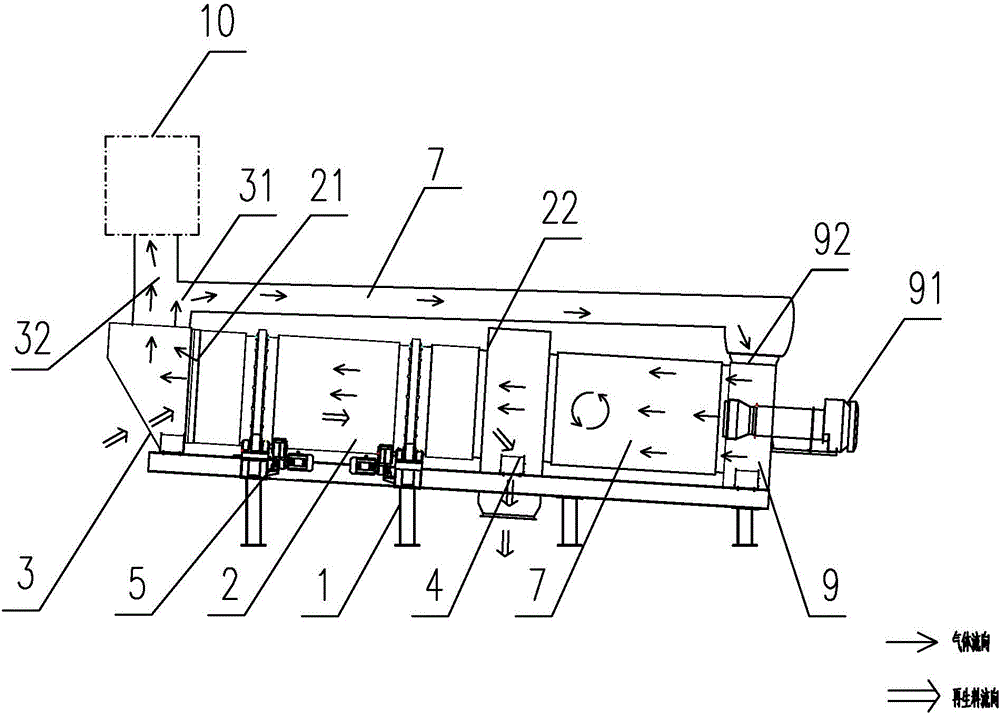

[0023] refer to figure 1 As shown, an asphalt regeneration drying drum includes a bitumen regeneration drying drum, including a support 1 and a cylinder 2 arranged on the support, a feed assembly 3, a discharge assembly 4, a driving device 5, and a combustion device 6 , high temperature flue gas mixing chamber 7, induced draft flue 8, combustion device 9, dust removal system 10;

[0024] The cylinder body 2 is arranged on the support 1 in an inclined arrangement with respect to the horizontal plane, the high part is the feed end 21, and the low part is the discharge end 22;

[0025] The feed assembly 3 is connected to the feed end 21, and the feed assembly 3 is provided with a smoke discharge port 31 and a dust outlet 32;

[0026] The discharge assembly 4 is connected to the discharge end 22;

[0027] The driving device 5 drives the cylinder body 2 to rotate so that the material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com