Water-spray screw steam compressor

A technology of steam compressors and compressors, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., and can solve problems such as lowering of exhaust steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

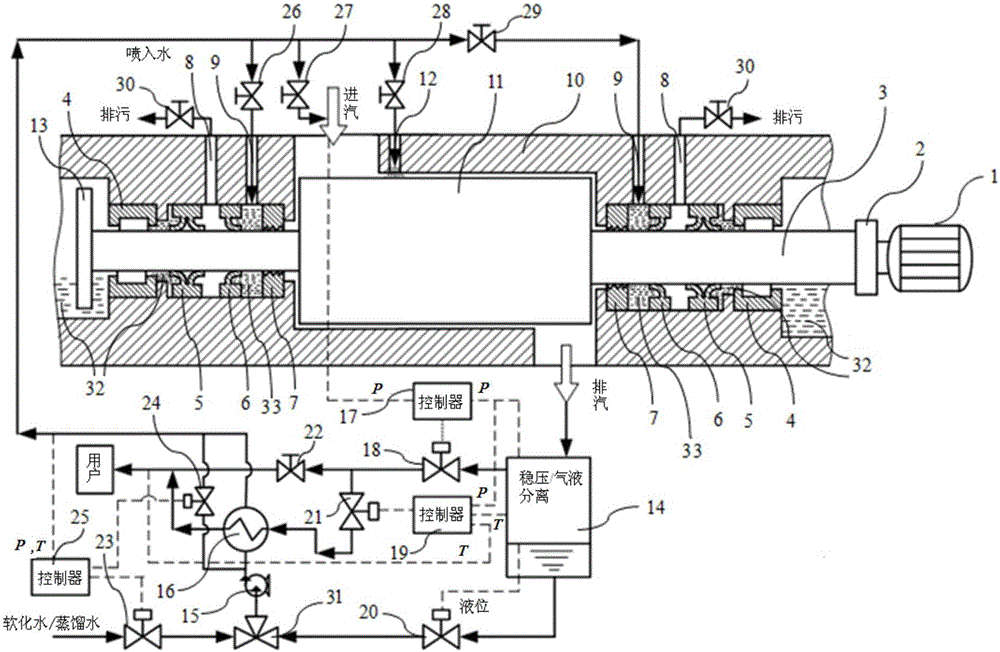

[0028] see figure 1 The water-sprayed screw steam compressor of the present invention comprises a screw compressor host, and the screw compressor host includes a drive source 1 (such as a motor), a transmission device 2 (such as a shaft coupling or a pulley), a screw rotor, and a compressor body 10. Screw rotor extension shaft 3, synchronous gear 13 and bearing 4, wherein the working section 11 of the screw rotor is located in the working chamber of the compressor body 10, and the screw rotor extension shaft located at one end of the working section 11 of the screw rotor 3 is connected to the drive source 1 through the transmission device 2, and the other end of the working section 11 of the screw rotor is connected to the synchronous gear 13. The compressor body 10 also has a bearing cavity, the bearing cavity is located on both sides of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com