Drying method of battery pole piece

A drying method and technology of battery pole pieces, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of cost increase, impact on enterprises, and high failure rate of NMP gas detectors, and achieve the effect of reducing recycling energy consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

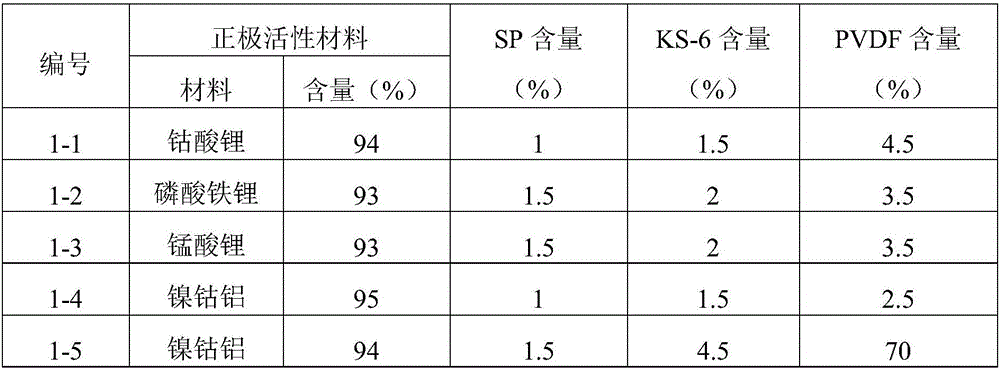

[0049] The cathode active material is used to prepare the cathode slurry, and its formula is shown in Table 1. The coating method is continuous coating by extrusion coating equipment. The parameters and conditions of coating and drying are shown in Table 2, wherein the gas concentration of LEL is 1.3%. The drying method is double-sided hot air drying; the NMP gas concentration is detected by the NMP gas detection alarm during the coating process, and the NMP recovery efficiency is calculated. The effect data are shown in Table 4.

[0050] Table 1: Formulation of Positive Electrode Piece

[0051]

[0052] Table 2: Parameters for coating and drying

[0053] Numbering

Embodiment 2

[0062] The positive electrode slurry was formulated with the positive electrode active material, and its formula was shown in 1-1 in Example 1, and the coating method was intermittent coating by extrusion coating equipment. The parameters and conditions of coating and drying are shown in Table 5, and the drying method is infrared drying. During the coating process, the NMP gas concentration was detected by the NMP gas detection alarm, and the effect data are shown in Table 6.

[0063] Table 5: Parameters for coating and drying

[0064] Numbering

drying temperature

gas concentration

Solid content

Coating surface density

Coating width

Transport speed

2-1

60℃

30% LEL

70%

30mg / cm 2

60cm

2m / min

2-2

70℃

55%LEL

58%

20mg / cm 2

40cm

4m / min

2-3

75℃

75%LEL

50%

25mg / cm 2

50cm

6m / min

2-4

80℃

98%LEL

60%

26mg / cm 2

70cm

8m / min

2-5

80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com