Multifunctional multi-mode electromagnetic flow control device of slab continuous casting crystallizer

A slab continuous casting, multi-mode technology, applied in the field of multi-functional multi-mode slab continuous casting mold electromagnetic flow control device, can solve the problems of low practicability, inability to adjust longitudinally, complex structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

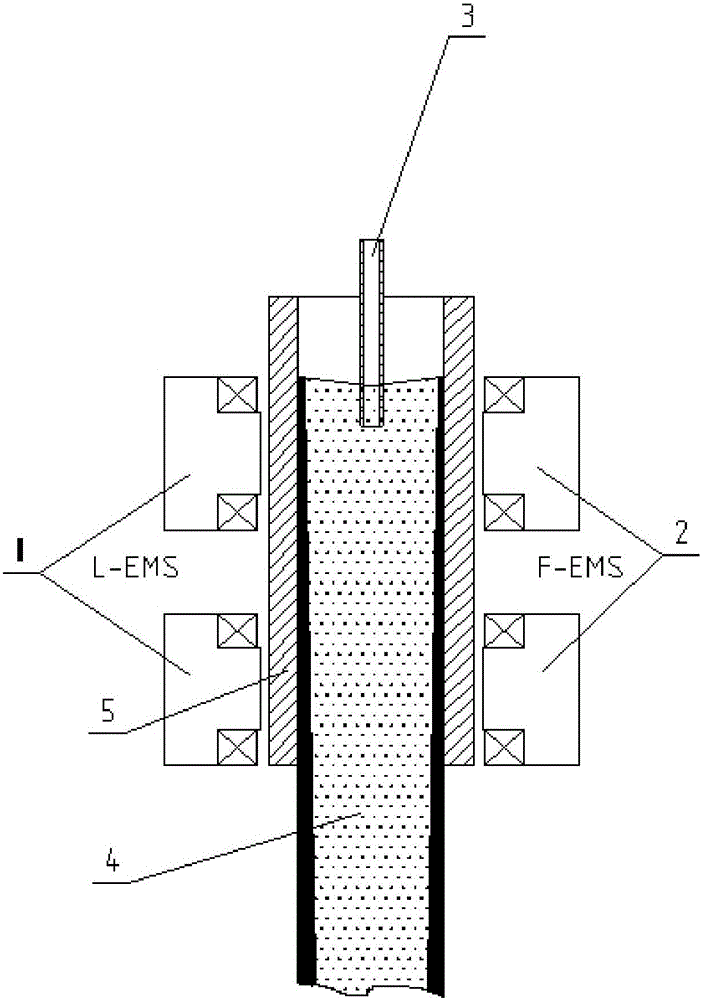

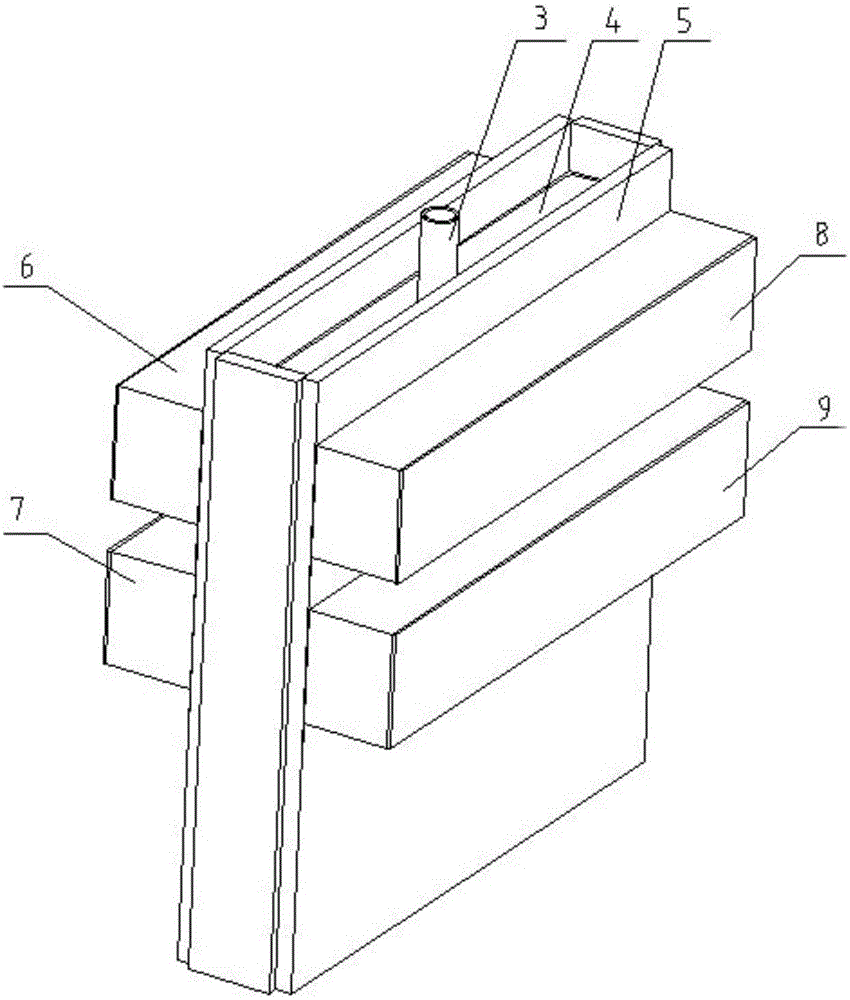

[0062] figure 1 It is a schematic diagram of the multi-functional multi-mode slab continuous casting mold electromagnetic stirring device of the present invention, which is divided into an inner arc electromagnetic stirrer (1) (abbreviated as L-EMS) and an outer arc electromagnetic stirrer (2) (abbreviated as F-EMS) , respectively arranged on the inner and outer arcs of the crystallizer copper plate (5). The molten steel (4) passes through the middle of the crystallizer copper plate (5).

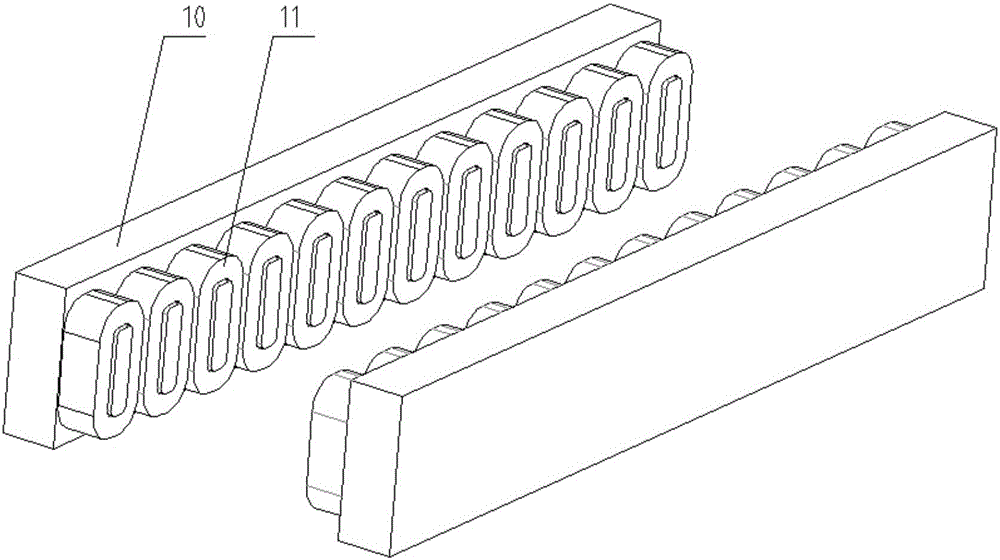

[0063] L—EMS(1) and F—EMS(2) respectively set up and down two sensors, respectively marked as L 1 (6), L 2 (7) and F 1 (8), F 2 (9); At the same time, L-EMS (1) and F-EMS (2) are respectively provided with four magnetic induction areas, and the four magnetic induction areas of L-EMS (1) are respectively marked as (101), (102), (103) , (104); the four magnetic induction areas of F-EMS (2) are respectively marked as (201), (202), (203), (204). The magnitude and direction of the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com