Ash sluicing water treatment and recycled water reuse system for ships

A treatment system and gray water technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve problems affecting effluent water quality, difficult layout, water consumption, etc., to improve effective utilization rate, reduce membrane The risk of blockage and the effect of overcoming the low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

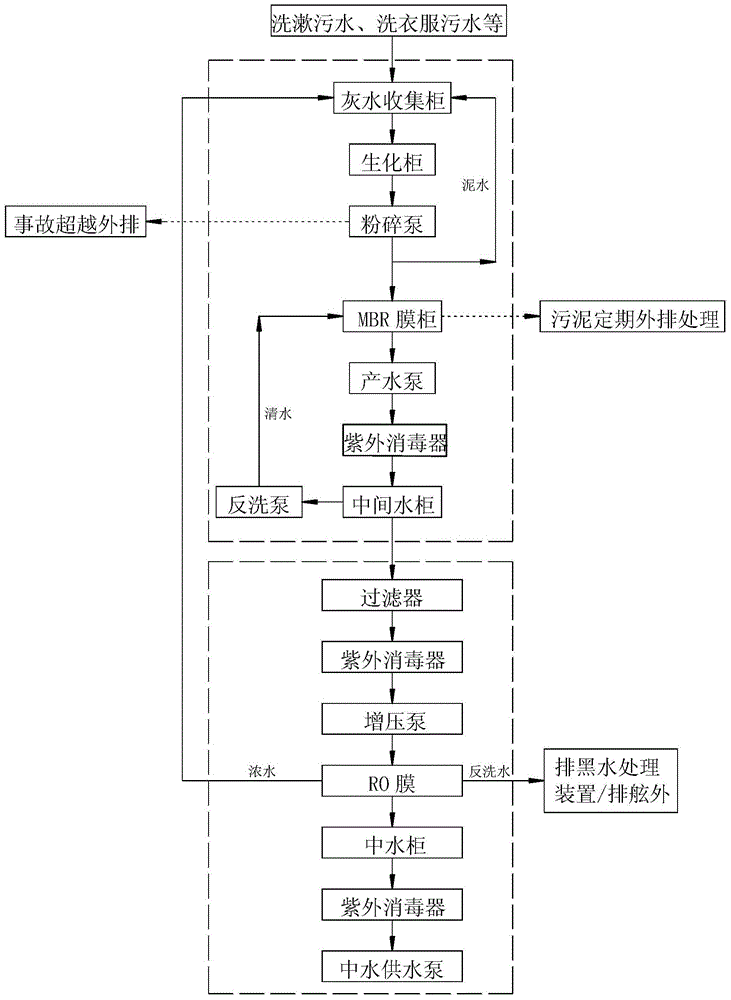

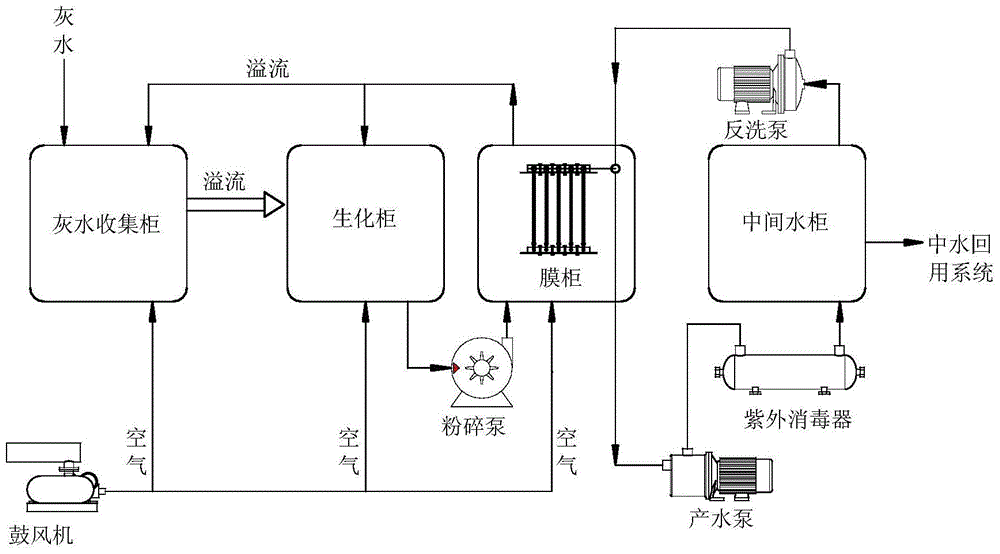

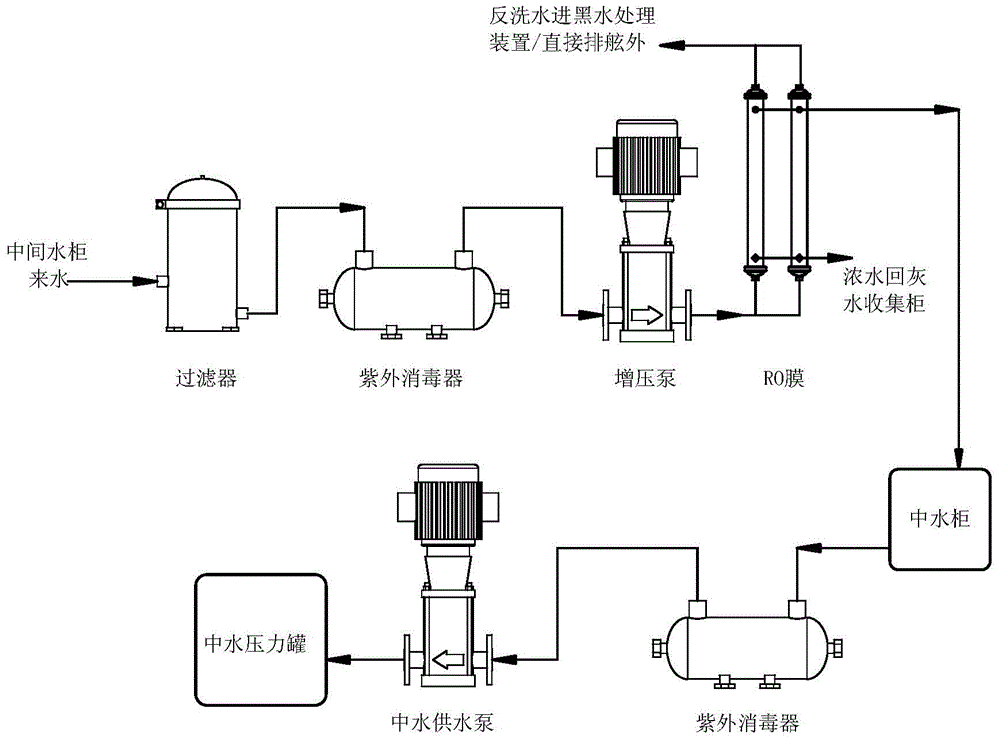

[0011] Gray water treatment and reclaimed water reuse system for ships includes gray water treatment system and reclaimed water reuse system. like figure 1 and figure 2 As shown, the gray water treatment system gray water treatment system includes gray water collection tank, biochemical tank, pulverizing pump, MBR (Membrane Bio-Reactor) membrane tank, product water pump, disinfection tank, intermediate water tank and intermediate water tank according to the direction of water flow. Part of the water flows through the backwash pump into the MBR membrane cabinet, and part of it enters the reclaimed water reuse system, and the various components of the system are connected by pipe fittings. Both the produced water pump and the backwash pump act on the MBR membrane, the former is to pump out the clear water in the MBR membrane, and the latter is to pump the clean water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com