Ageing strengthening magnesium alloy with evenly-distributed granular quasi crystals and rod-like phases and preparation method

A technology of uniform distribution and aging strengthening, applied in the field of alloys, to achieve the effects of simple steps, easy control of conditions and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

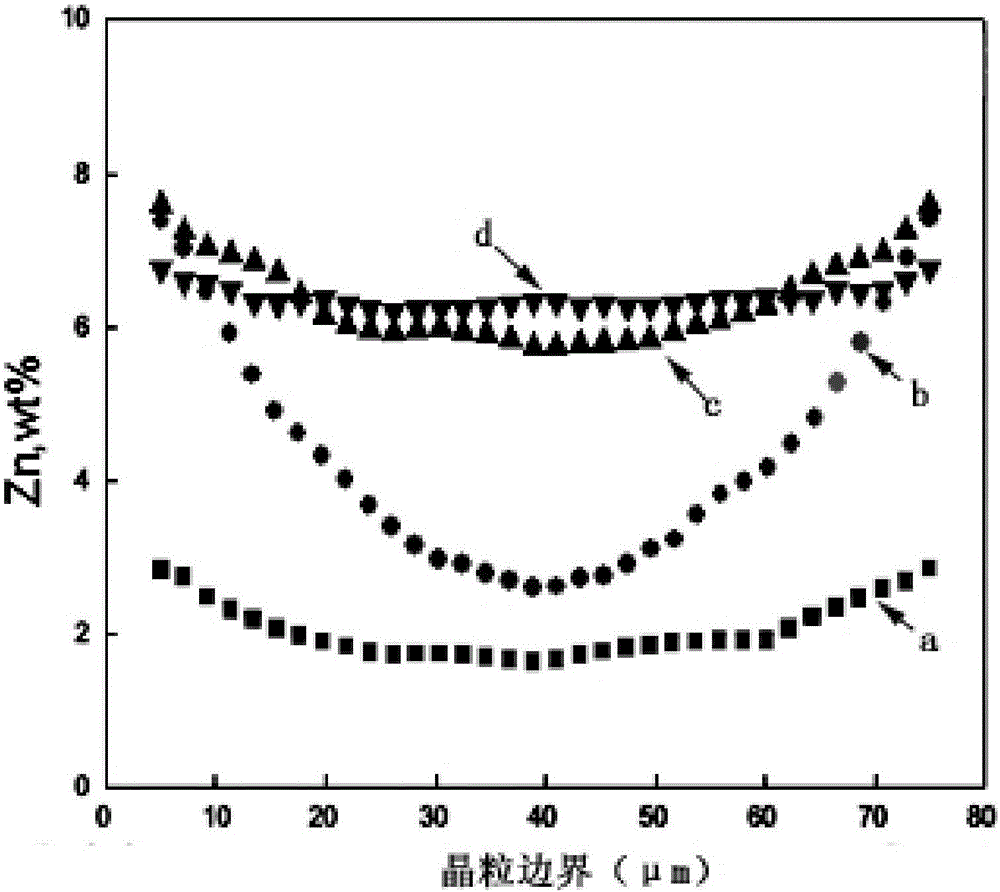

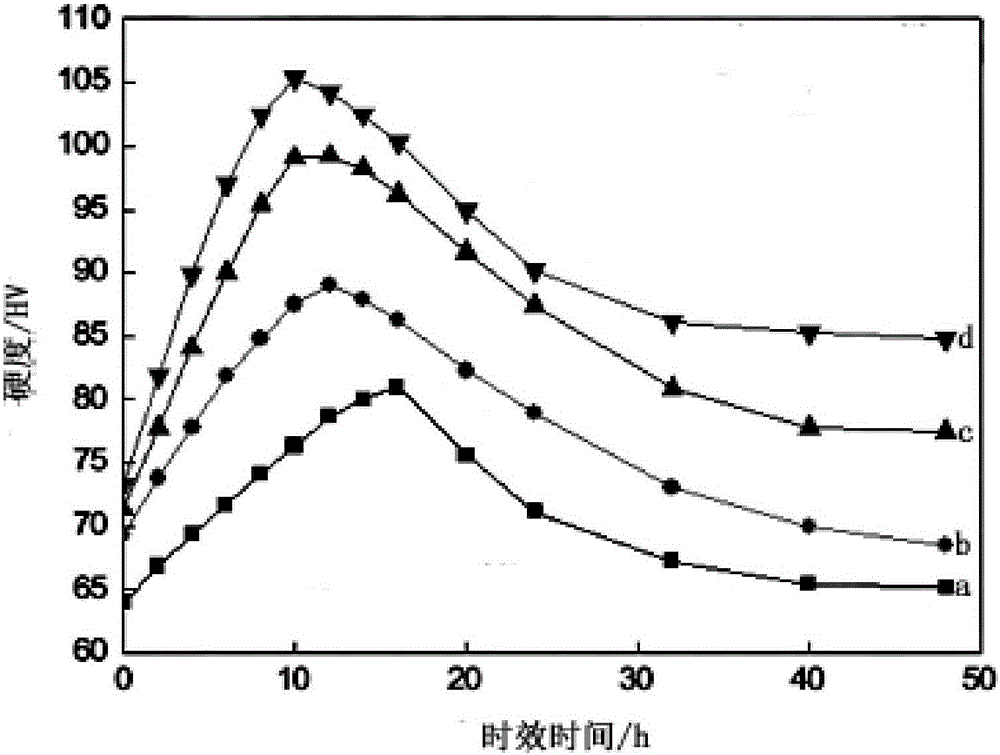

[0035] An age-strengthened magnesium alloy with evenly distributed granular quasicrystals and rod-like phases is a Mg-Zn-Y alloy, in which Mg: 89wt.%~93wt.%, Zn: 6wt.%~8wt.%, Y: 1wt.%~3wt .%.

[0036] A method for preparing an aging-strengthened magnesium alloy with uniformly distributed granular quasicrystals and rod-like phases, specifically comprising the following steps:

[0037] S1, the preparation of as-cast Mg-Zn-Y alloy material:

[0038] S1.1. Weigh magnesium ingots, zinc ingots and Mg-30Y master alloy, preheat and bake, and set aside;

[0039] S1.2. When the temperature of the crucible is raised to the previous temperature in the crucible resistance furnace, add the magnesium and zinc ingots treated in S1.1, pass through the protective gas, continue to heat up until the magnesium and zinc ingots are melted, and then add S1 . The Mg-30Y master alloy treated in 1 is stirred for 2-5 minutes after the Mg-30Y master alloy is melted. After the stirring is completed, it i...

Embodiment 2

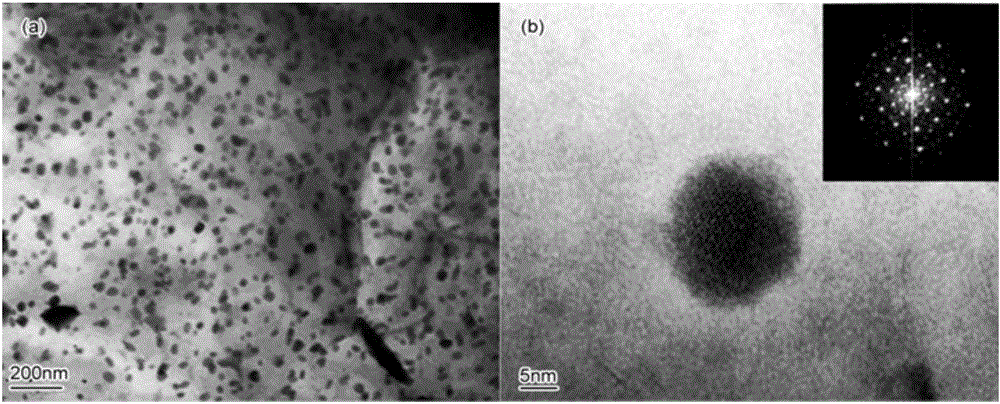

[0043] The age-strengthened magnesium alloy with evenly distributed granular quasicrystals and rod-like phases is a Mg-Zn-Y alloy, wherein Mg: 89wt.%, Zn: 8wt.%, Y: 3wt.%. In the alloy, rod-like β is uniformly and dispersedly distributed on the magnesium matrix 1 '-MgZn 2 and granular icosahedral quasicrystalline phase, the solid solubility of Zn element in the magnesium matrix is >6wt.%.

[0044] A method for preparing an aging-strengthened magnesium alloy with uniformly distributed granular quasicrystals and rod-like phases, specifically comprising the following steps:

[0045] S1, the preparation of as-cast Mg-Zn-Y alloy material:

[0046] S1.1. Weigh magnesium ingots, zinc ingots and Mg-30Y master alloy with a mass ratio of 89︰8︰9, preheat and bake at 200°C, and set aside;

[0047] S1.2. When the temperature of the crucible is raised to 350°C in the crucible resistance furnace, add the magnesium ingots and zinc ingots treated in S1.1, and introduce CO 2 / SF 6 The mi...

Embodiment 3

[0051] The age-strengthened magnesium alloy with evenly distributed granular quasicrystals and rod-like phases is a Mg-Zn-Y alloy, wherein Mg: 93wt.%, Zn: 6wt.%, Y: 1wt.%. In the alloy, rod-shaped β′ is uniformly and dispersedly distributed on the magnesium matrix 1 -MgZn 2 and granular icosahedral quasicrystalline phase, the solid solubility of Zn element in the magnesium matrix is >6wt.%.

[0052] A method for preparing an aging-strengthened magnesium alloy with uniformly distributed granular quasicrystals and rod-like phases, specifically comprising the following steps:

[0053] S1, the preparation of as-cast Mg-Zn-Y alloy material:

[0054] S1.1. Weigh magnesium ingots, zinc ingots and Mg-30Y master alloy with a mass ratio of 93︰6︰3, preheat and bake at 200°C, and set aside;

[0055] S1.2. When the temperature of the crucible is raised to 400°C in the crucible resistance furnace, add the magnesium ingots and zinc ingots treated in S1.1, and introduce CO 2 / SF 6 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com