A kind of hot air blowing bulk material device and using method thereof

A technology of hot air injection and hot air, which is applied in combustion methods, lighting and heating equipment, combustion types, etc., and can solve problems such as small contact area between hot smoke and air, various types of solid waste, convective heat transfer, and weakened combustion , to improve the effect of incineration treatment, avoid deformation, and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

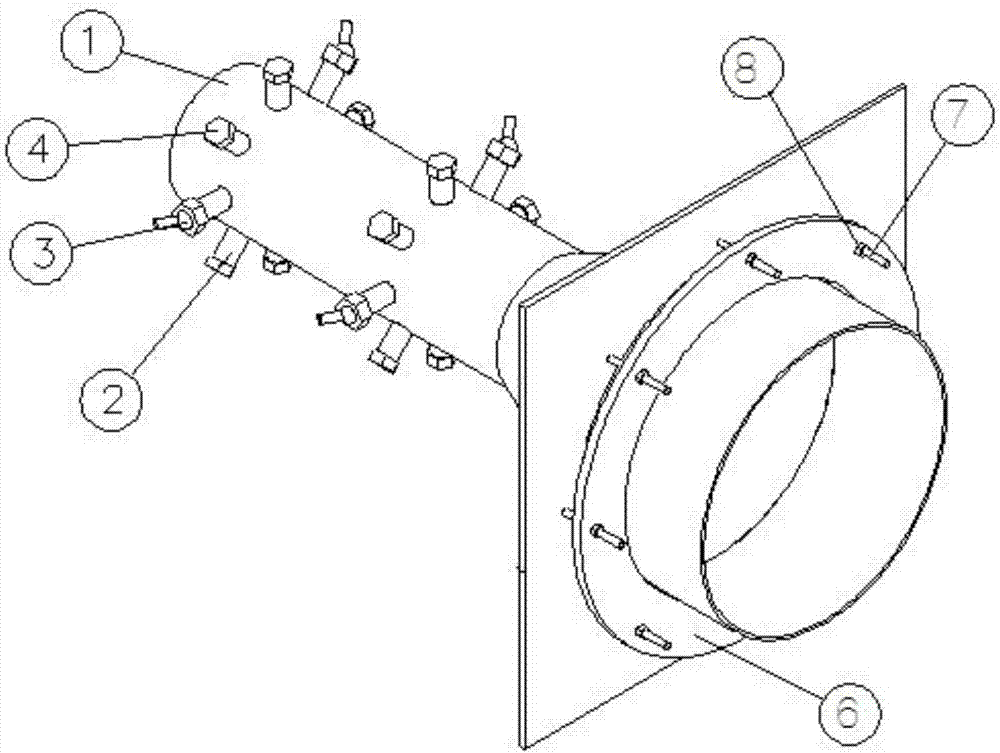

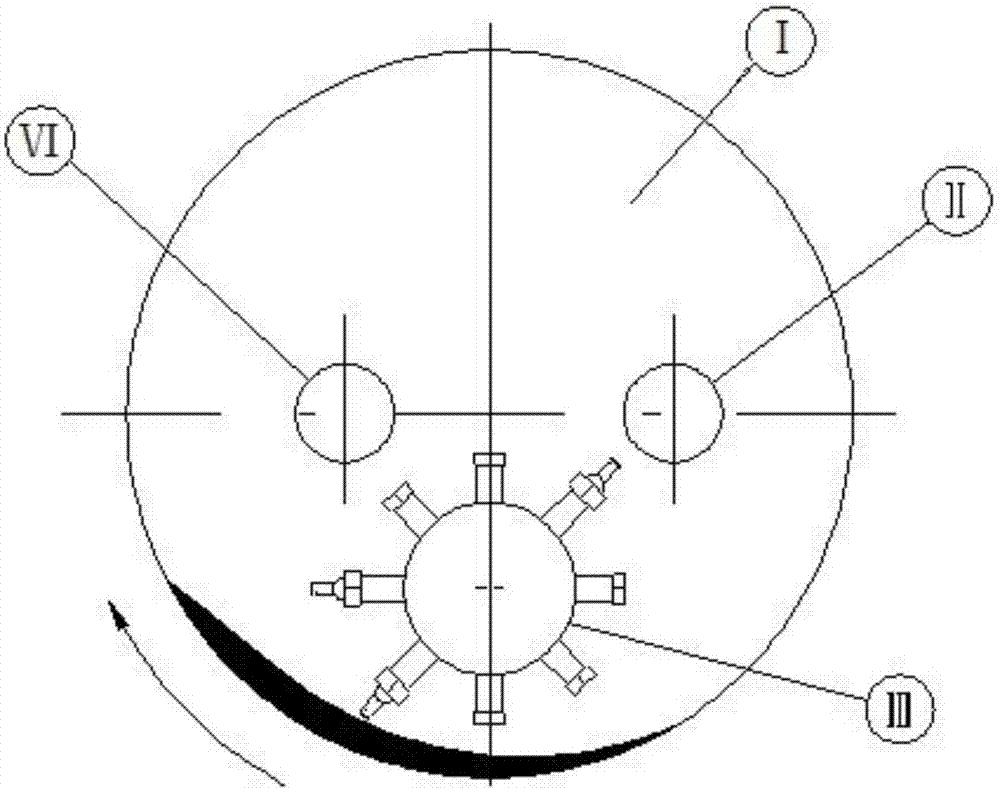

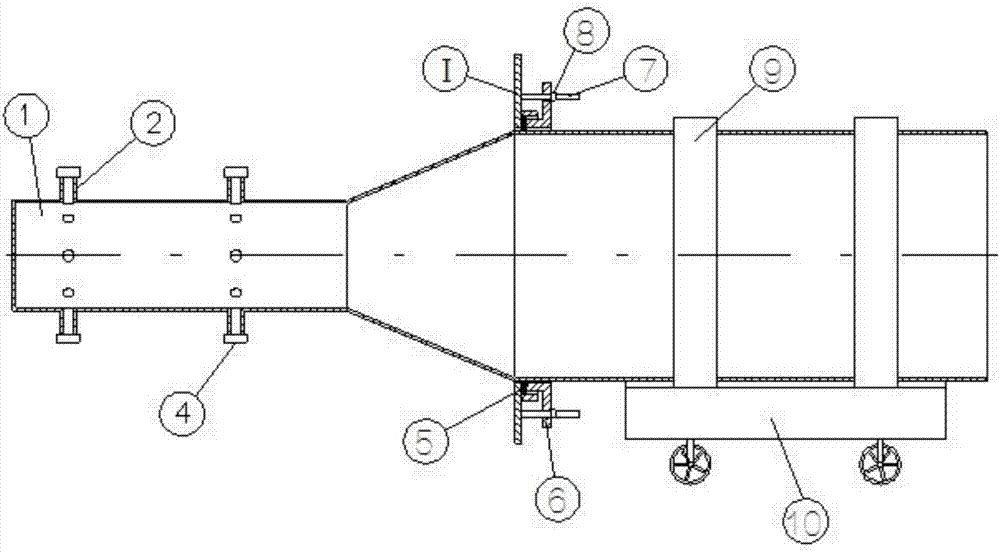

[0027] like Figure 1-Figure 3 As shown, a hot air blowing bulk material device according to the present invention is used to blow the powdery material on the inlet pipe II nozzle of the rotary kiln for solid waste incineration and the powdery material on the wall of the kiln barrel. II is fixed on the kiln head end plate I of the rotary kiln and extends into the rotary kiln; it includes the hot air injection pipe III and the mobile trolley 10; the hot air injection pipe III is composed of the main injection pipe 1 and the injection branch pipe 2. The branch pipe 2 is arranged along the axial and circumferential direction of the injection main pipe 1; the universal nozzle 3 or the injection branch pipe plug 4 can be optionally installed on the injection branch pipe 2; the injection main pipe 1 is fixed on the mobile trolley 10, and after moving an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com