Gas sensor array concentration detection method based on fuzzy division and model integration

A gas sensor, fuzzy division technology, applied in the direction of material resistance, etc., can solve the problems of not considering the difference in importance, the prediction accuracy needs to be improved, and the degree of drift change is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The data set used in this embodiment is a data set measured and published by A Vergara, S Vembu, T Ayhan, M Ryan, M Homer, R Huerta et al. For literature, see "Chemical gas sensor drift compensation using classifier ensembles." Sensors and Actuators B: Chemical 166(2012):320-329. The sensor array is composed of TGS2600, TGS2602, TGS2610 and TGS26204 from Figaro Company, each with 4 gas sensors and a total of 16 gas sensors. Test gases include ammonia, acetaldehyde, acetone, ethylene, ethanol, and toluene. Each sensor extracts 8 signal features for each sample, including two steady-state features and 6 transient features. Therefore, a 128-dimensional feature vector can be obtained from the sensor array for each test. The test lasted for three years (36 months), with a total of 13,910 measurements. That is, the data set is a matrix of 13910×128.

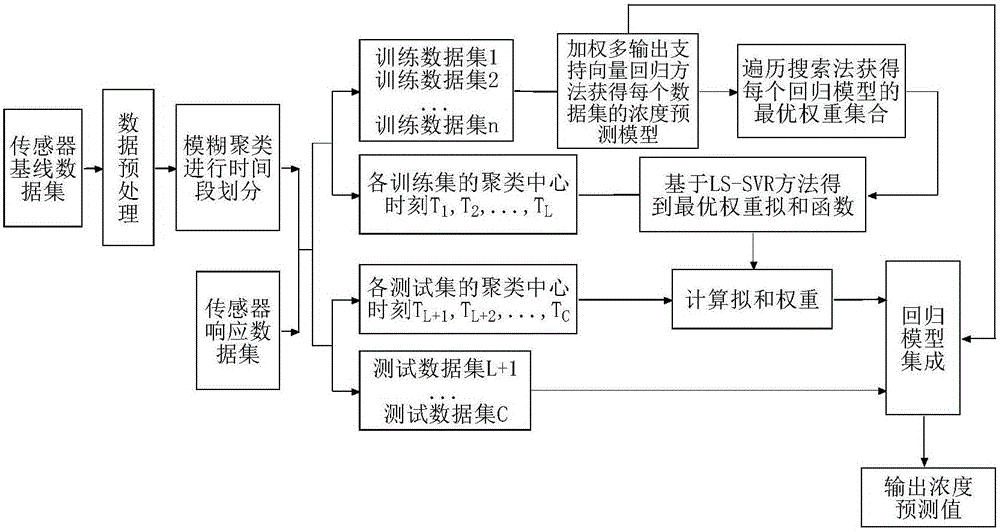

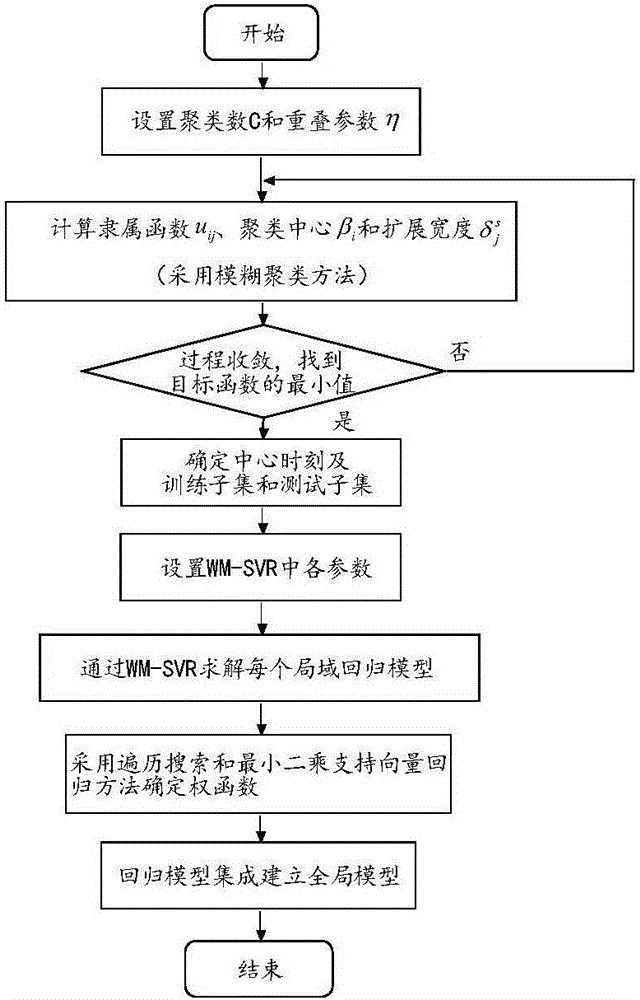

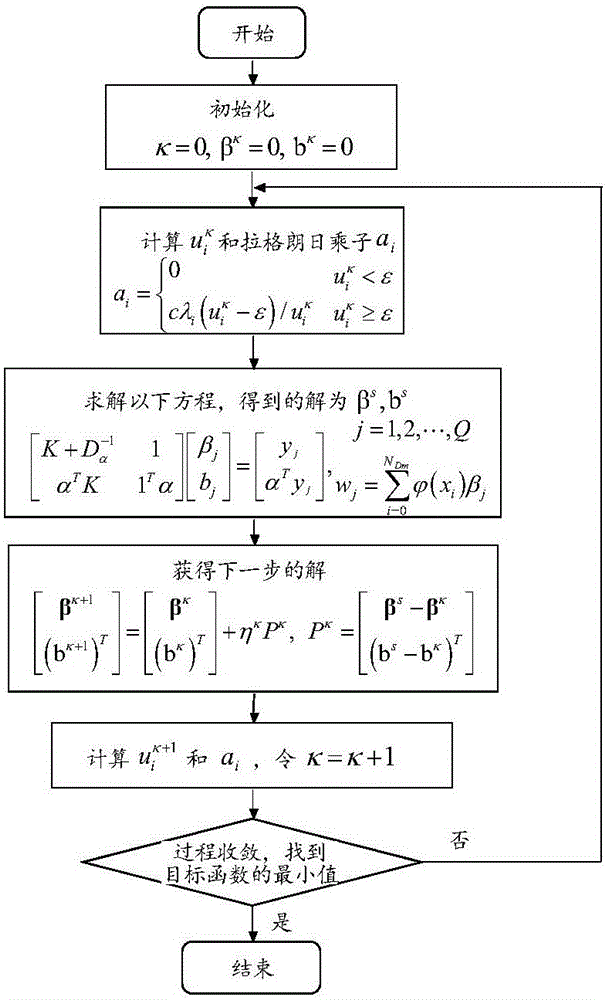

[0065] Such as figure 1 As shown, the drift compensation method of metal oxide gas sensor array concentration detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com