Method for precisely simulating performance of photovoltaic battery piece

A technology of photovoltaic cells and cells, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as complex equivalent circuit equations of double diode models, complex calculation methods, and simulation errors of single diode simulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

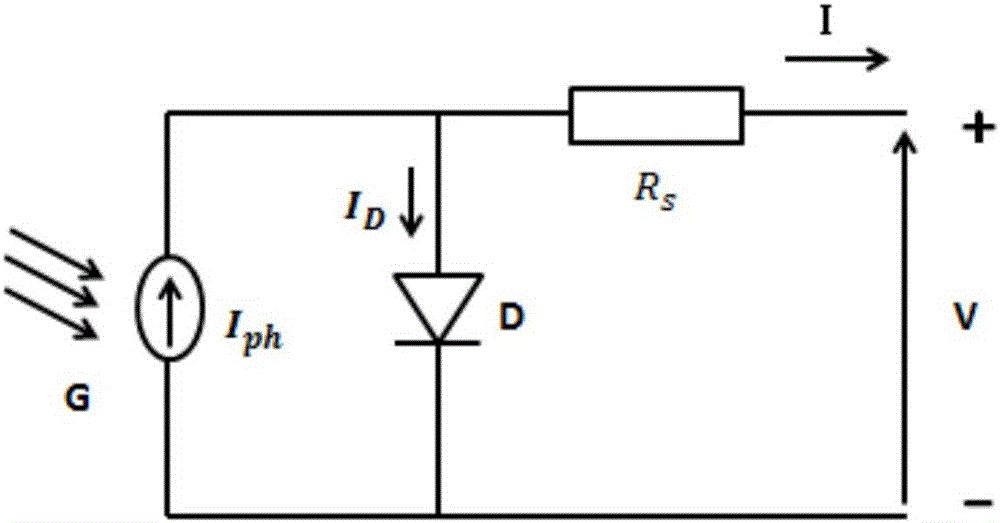

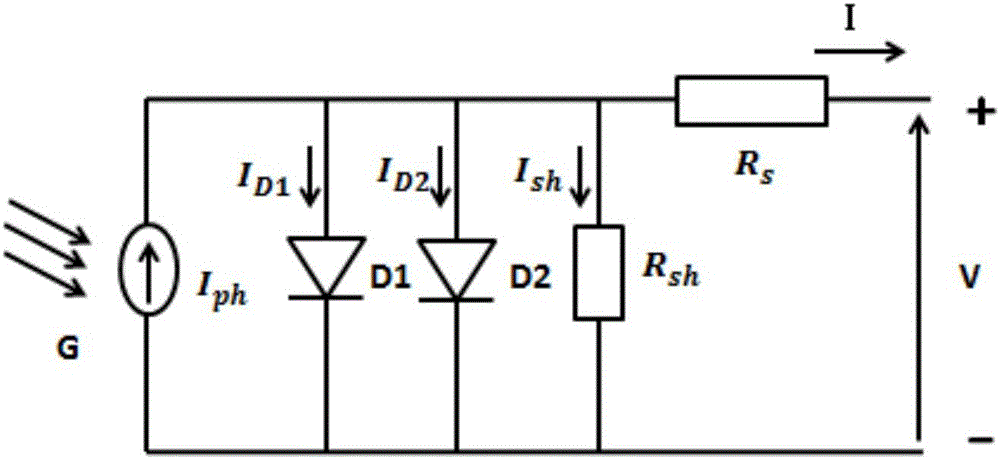

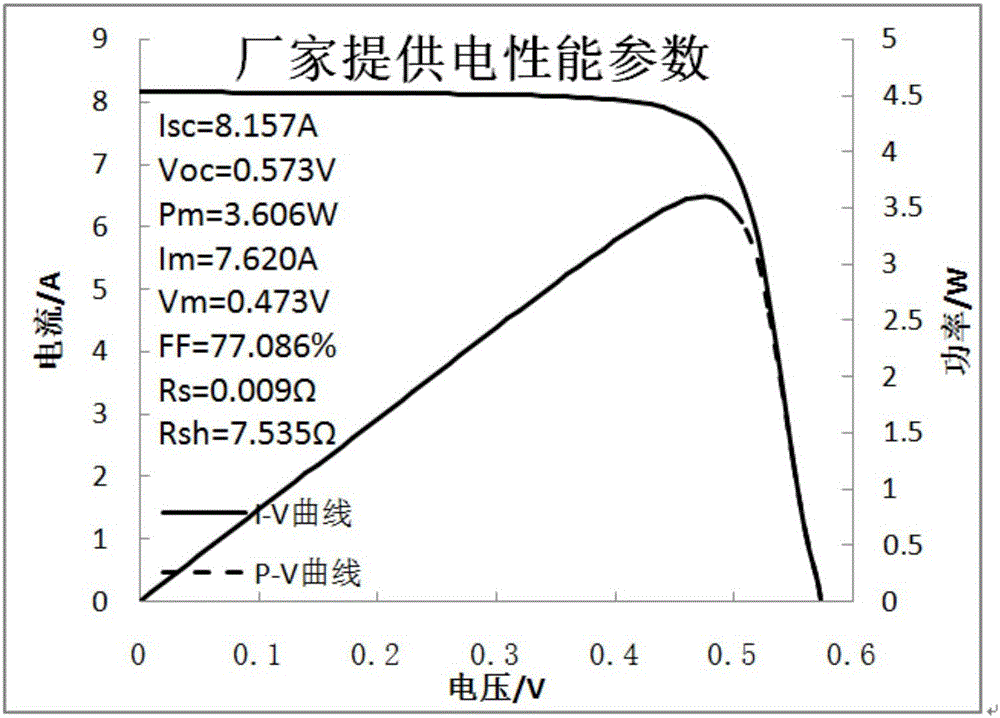

[0066] image 3 It is the electrical performance parameter of the battery provided by the battery manufacturer. It is tested under standard conditions (AM1.5 spectrum, light intensity 1000W / m2, 25°C), and a 3A-level solar simulator is used. Figure 4 is simulated using a single diode equivalent model, ignoring the parallel resistance R sh effect, because R sh The resistance value is relatively large, ignoring R sh The original single diode model can be turned into an explicit equation, and the accuracy of the simulation can be guaranteed to a certain extent. Set according to the relevant technical parameters provided by the battery manufacturer, and set the working current from 0 to the short-circuit current I sc So far, the step size is set to 0.001A, then a series of working voltage values can be obtained, and the curve can be drawn to obtain the I-V curve of the cell. Figure 5 Be the I-V curve that adopts the double diode model simulation of the inventive method, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com