Electrolytic capacitor middle-high voltage electrolyte and preparation method thereof

A technology for electrolytic capacitors and aluminum electrolytic capacitors, applied in the field of high-voltage electrolyte and its preparation, can solve the problems of high temperature resistance and short life, and achieve the effects of excellent high temperature resistance, high flash voltage, and improved oxidation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Embodiment 1, percent by weight is: ethylene glycol 62%, pure water 3%, nanometer SiO 2 Ethylene glycol solution 13%, alkyl ammonium sebacate and ammonium salt mixture 20.5%, monobutyl phosphate 1%, hydrogen suppressant 0.5%.

[0021] Embodiment 2, percent by weight is: ethylene glycol 68%, pure water 3%, nanometer SiO2 Ethylene glycol solution 5%, half-esterified carboxylate ammonium salt and ammonium salt mixture 22%, monobutyl phosphate 1%, disinfectant Hydrogen agent 1%.

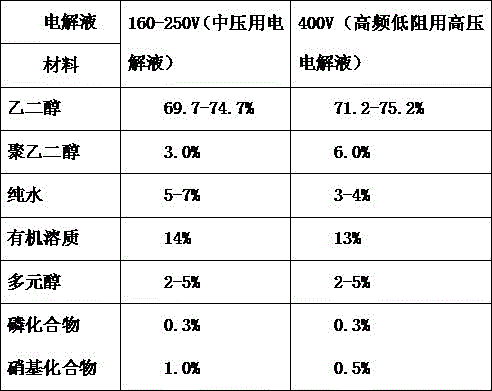

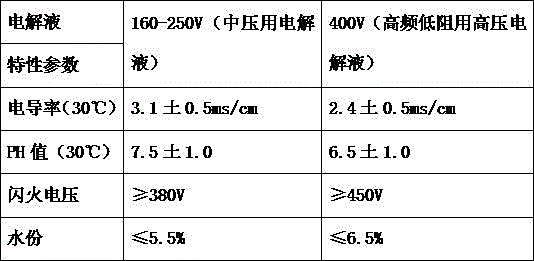

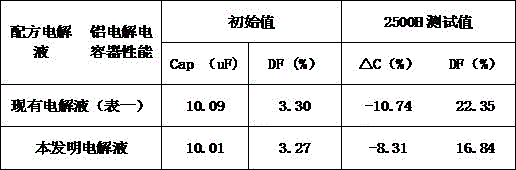

[0022] The characteristics of the electrolyte solution configured in the present invention are shown in the following table (Table 3).

[0023] Characteristic parameters

160-250V (for medium voltage) and 400V (for high frequency and low resistance)

Conductivity (30°C)

2.8 soil 0.5ms / cm

PH value (30°C)

6.5 soil 1.0

Flash voltage

≥460V

≤3%

[0024] The invention provides a kind of preparation method of electrolytic solution, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com