Movable ultrasonic stirring cleaning tank and method for repairing heavy metal contaminated soil

A technology of polluted soil and ultrasonic stirring, which is applied in the field of environmental pollution control, can solve the problems of secondary pollution of the environment around the equipment, affecting the efficiency of soil remediation, and the inability to continuously feed and discharge materials, etc., to solve the problem of container vibration and height difference Problems, improvement repair effect, effect of low installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

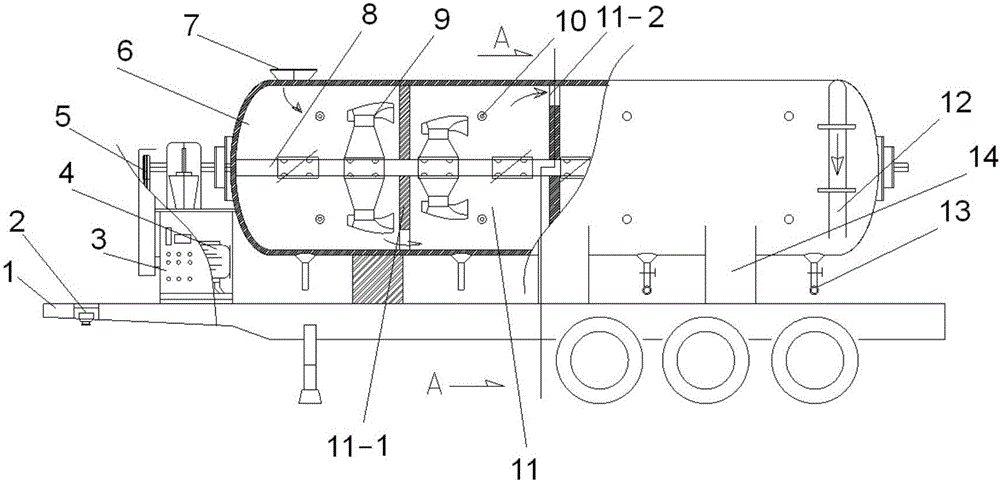

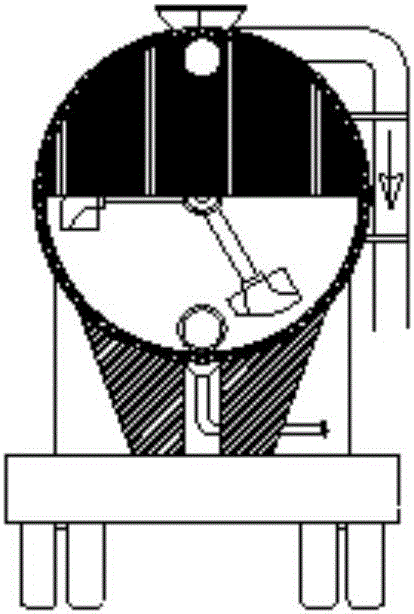

[0031] Such as figure 1 with 2 shown. The invention discloses a movable ultrasonic stirring cleaning tank for repairing polluted soil, which comprises a bracket 1, a tank body 6 arranged on the bracket 1, a stirring shaft 8 arranged in the tank body 6, and multiple sets of stirring shafts 8 axially installed The stirring paddle 9 for stirring and pushing the material (the mixed material liquid of the soil to be repaired and the cleaning agent) on the top, and the driving mechanism for driving the stirring shaft 8 to rotate; the material is sent into the tank body 6 by the feed port 7, and the Under the stirring and pushing action of the paddle 9, it is discharged from the discharge port 12;

[0032] A plurality of chambers 11 (stirring chambers) separated by partitions 11-1 are provided in the axial direction of the tank body 7; the stirring shaft 8 passes through each partition 11-1 successively, and each chamber A group of stirring paddles 9 are distributed in 11; a commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com