Wide thin-wall roller

A thin-walled, wide-width technology, applied in the field of plastic film processing equipment, can solve the problems of low roller cooling efficiency, slow film cooling, uneven thickness, etc., and achieve the effects of small deformation, fast cooling speed, and overall strength enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

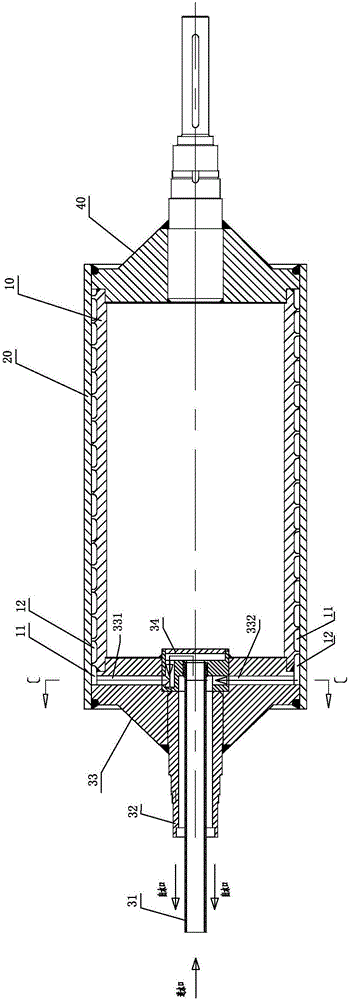

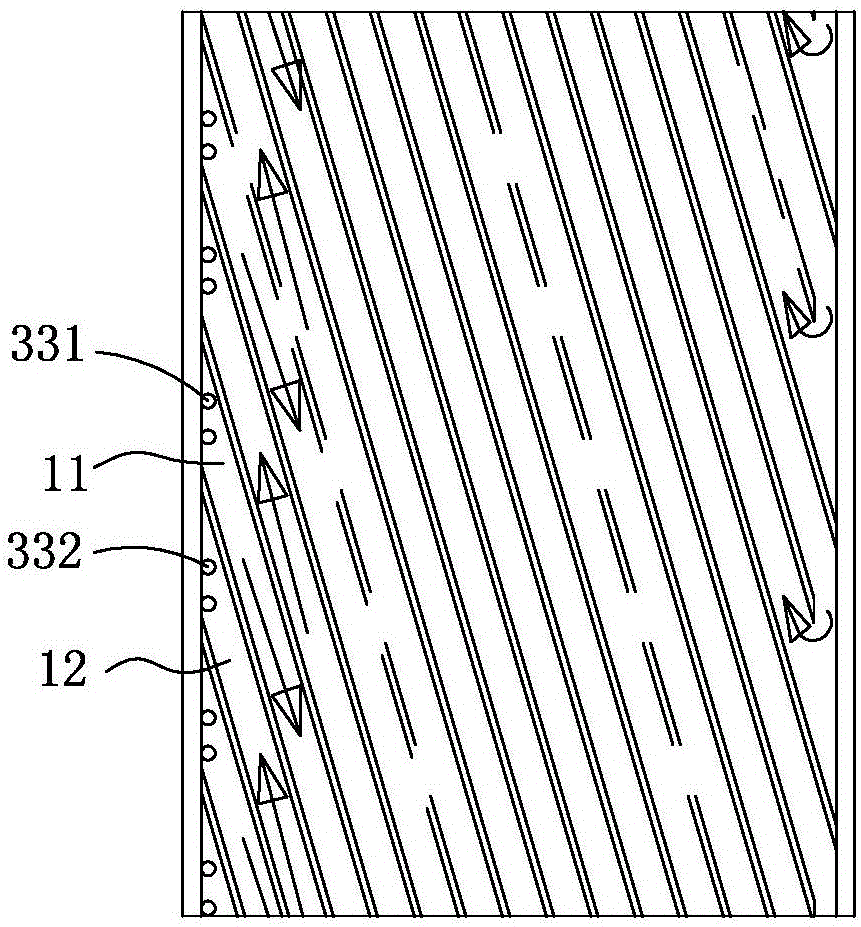

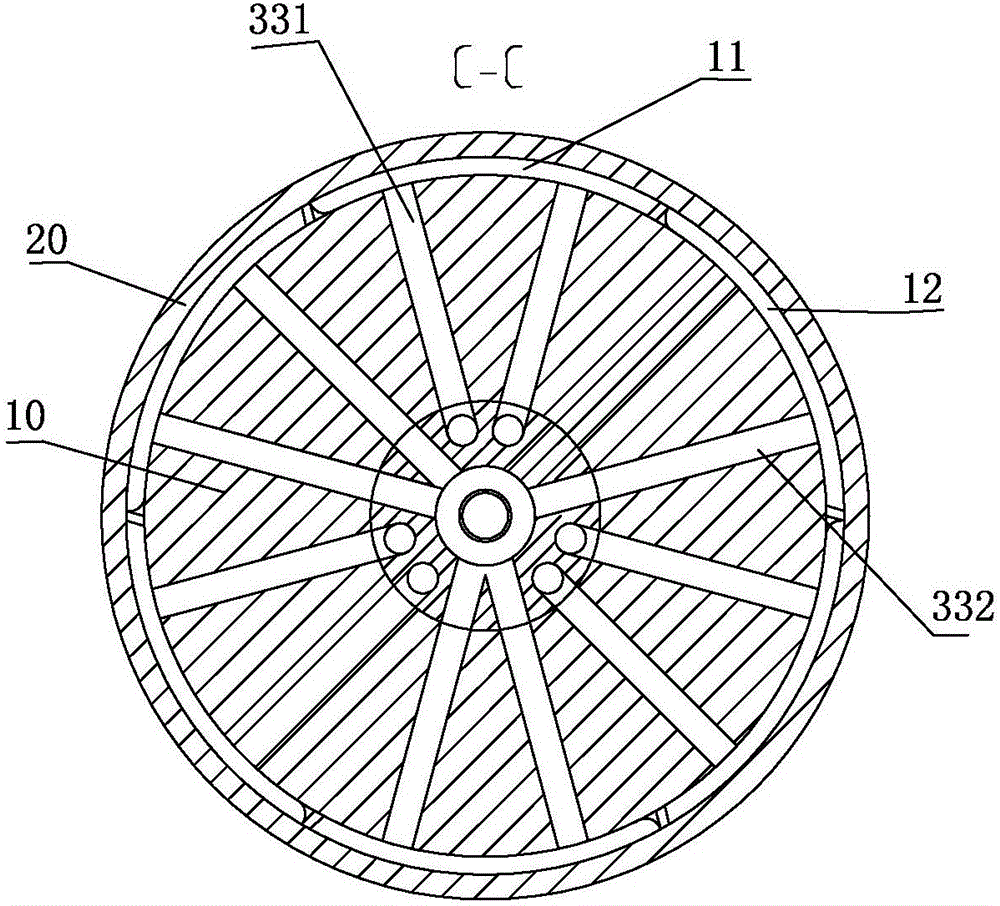

[0015] See attached figure 1 As shown in -3, a wide-width thin-walled roller includes: an inner tank 10 with multiple parallel spiral flow channels on the outer surface, an outer roller 20 that is interference fit with the inner tank, and is respectively arranged in the inner tank. The first shaft head assembly and the second shaft head assembly 40 at the left and right ends of the liner 10, the inner liner 10 is made of extra-thick wall seamless steel pipe, which can not only enhance the overall rigidity, but also reduce the The deflection deformation of the outer roller. The spiral flow channel is formed by milling spiral ribs on the inner tank body, and the arc transition at the bottom of the spiral ribs is beneficial to reduce the resistance of water. The outer roller 20 adopts thin-walled alloy steel. Because the roller surface is thin-walled, the heat conduction is fast and the cooling effect is good. In order to increase the strength of the outer roll, the inner liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com