Polyurethane composite material containing natural plant compositions and preparation method thereof

A technology of natural plants and composite materials, applied in the field of polyurethane composite materials and its preparation, can solve problems such as air pollution, affecting experience, and inability to degrade naturally, and achieve the effects of high porosity, stable structure, and air pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

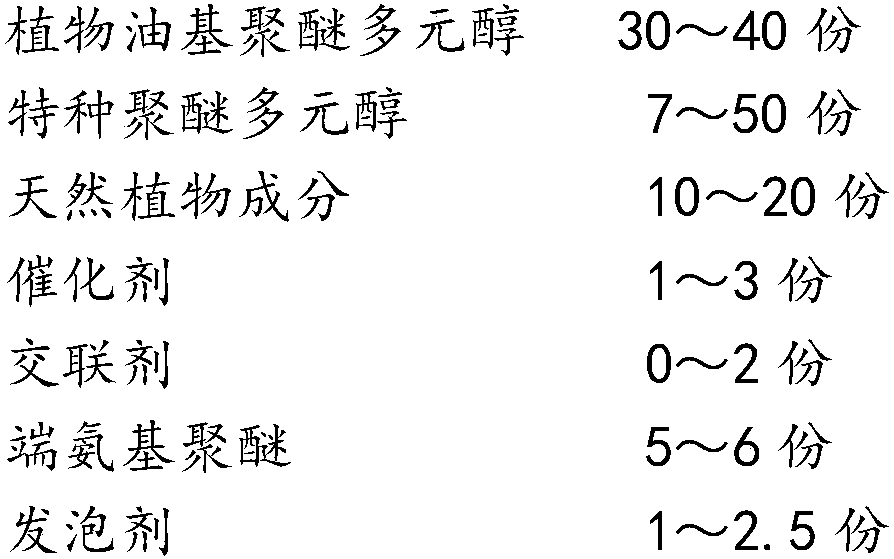

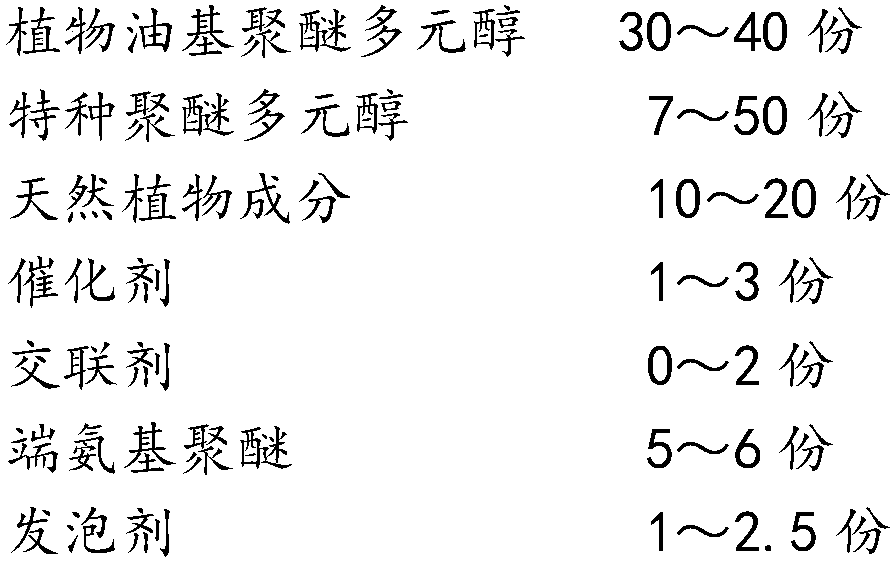

Method used

Image

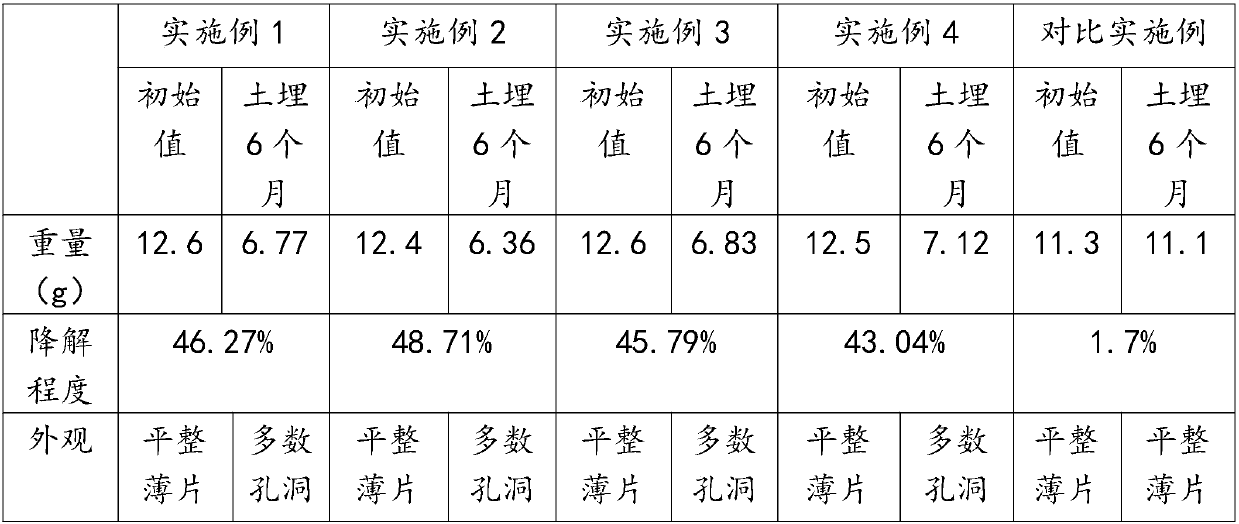

Examples

Embodiment 1

[0022] Weigh respectively 30 parts by weight of castor oil-based polyether polyol, 50 parts by weight of special polyether polyol, 10 parts by weight of coffee bean dregs powder, 1 part by weight of catalyst, 2 parts by weight of crosslinking agent, 5 parts by weight of amino-terminated polyol Ether and 1.5 parts by weight of foaming agent were stirred and mixed to obtain group A material, and then 40 parts by weight of isocyanate of group A and group B were stirred and mixed, and reacted and formed at a temperature of 60°C.

[0023] Among them, the castor oil-based polyether polyol is selected such as EBT 320i from Mitsui, Japan; the special polyether polyol is selected from NJ-2442 of Ningwu Jurong Company; the amino-terminated polyether is selected from T-403 polyetheramine of Huntsman Company of the United States; The blowing agent is a mixture of water and fluorodichloroethane; the catalyst is an amine catalyst of Niax A-33 from Momentive Company of the United States; the ...

Embodiment 2

[0025] Weigh respectively 40 parts by weight of castor oil-based polyether polyol, 30 parts by weight of special polyether polyol, 20 parts by weight of green tea residue powder, 1.5 parts by weight of catalyst, 2 parts by weight of crosslinking agent, 6 parts by weight of amino-terminated polyol Ether and 2.5 parts by weight of foaming agent were stirred and mixed to obtain group A, and then 35 parts by weight of isocyanate of group A and group B were stirred and mixed, and reacted and formed at a temperature of 40°C.

[0026] Among them, the castor oil-based polyether polyol is selected such as EBT 320i from Mitsui, Japan; the special polyether polyol is selected from NJ-2442 of Ningwu Jurong Company; the amino-terminated polyether is selected from T-403 polyetheramine of Huntsman Company of the United States; The blowing agent is fluorodichloroethane; the catalyst is Niax A-33 or D-2000 amine catalyst of American Momentive Company; the isocyanate is diphenylmethane diisocyan...

Embodiment 3

[0028] Weigh respectively 35 parts by weight of castor oil-based polyether polyol, 50 parts by weight of special polyether polyol, 20 parts by weight of coffee bean dregs powder, 2 parts by weight of catalyst, 0 part by weight of crosslinking agent, 5 parts by weight of amino-terminated polyol Ether and 1.5 parts by weight of foaming agent were stirred and mixed to obtain group A material, and then 30 parts by weight of isocyanate of group A and group B were stirred and mixed, and reacted and formed at a temperature of 60°C.

[0029] Among them, the castor oil-based polyether polyol is selected such as EBT 320i from Mitsui, Japan; the special polyether polyol is selected from NJ-2442 of Ningwu Jurong Company; the amino-terminated polyether is selected from T-403 polyetheramine of Huntsman Company of the United States; The blowing agent is two mixtures of water and fluorodichloroethane; the catalyst is the amine catalyst of Niax A-33 of American Momentive Company; the isocyanate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com