A high-efficiency heat dissipation coating and its application method

A heat-dissipating coating and high-efficiency technology, applied in the coating and other directions, can solve problems such as affecting the reliability of electronic equipment, affecting and shortening the service life of electrical equipment, and achieve the effect of uniform heat dissipation, high infrared radiation performance, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for applying a high-efficiency heat dissipation coating, the method comprising the steps of:

[0032] (1). Clean and dry the metal heat sink surface of electronic equipment with deionized water;

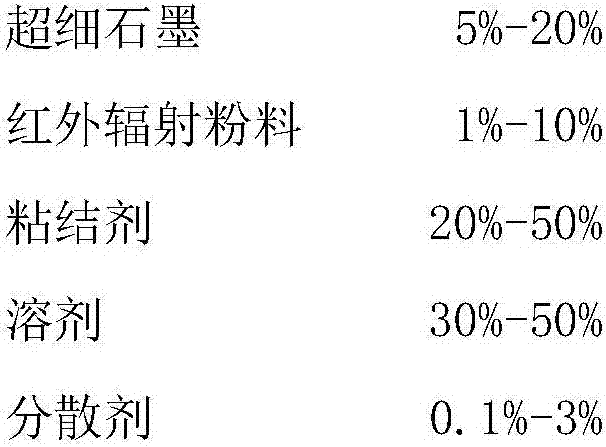

[0033] (2). According to the composition and mass percentage of the material, 10% of ultra-fine graphite, 7% of infrared radiation powder, 35% of binder, 47% of solvent and 1% of dispersant,

[0034] The sum of the distribution ratios of the various components is 100%, and the above-mentioned ultrafine graphite, infrared radiation powder, binding agent, and dispersant

[0035] Mix with a solvent, mix the ingredients, and stir evenly to obtain a slurry;

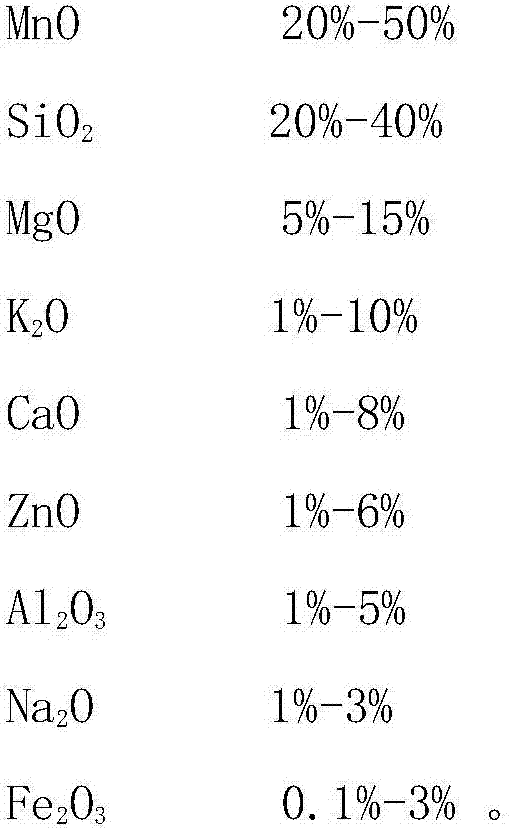

[0036] Wherein the binder is epoxy modified acrylic resin; the solvent is xylene; the particle size of the infrared radiation powder is 1.3 μm, and the composition and mass percentage are:

[0037] MnO 39.7%

[0038] SiO 2 29.7%

[0039] MgO 9.3%

[0040] K 2 O 5.7%

[0041] CaO 4.7%

[0042] ZnO 4.2%

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com