Environment-friendly anticorrosion and temperature-reduction integrated paint for storage tank and preparation method of paint

An environment-friendly coating technology, applied in anti-corrosion coatings, chemical instruments and methods, coatings, etc., can solve the problems of large breathing loss of oil and gas and chemical raw materials, poor safety of coating coating process, harmful environment and human health, etc. Achieve significant protection, long outdoor service life, and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

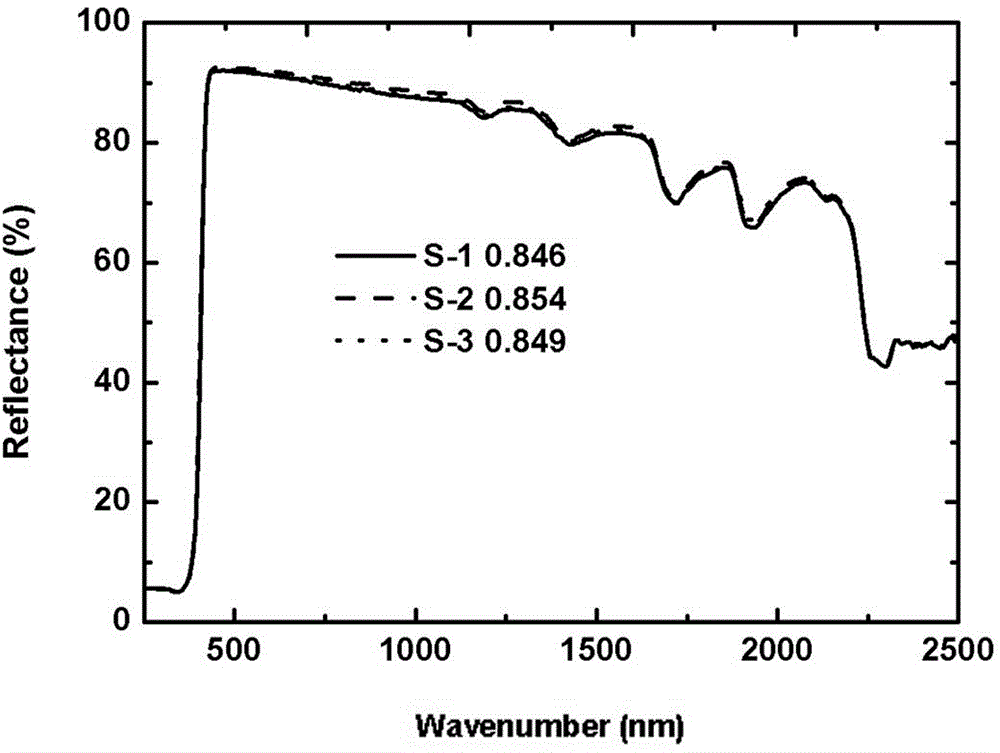

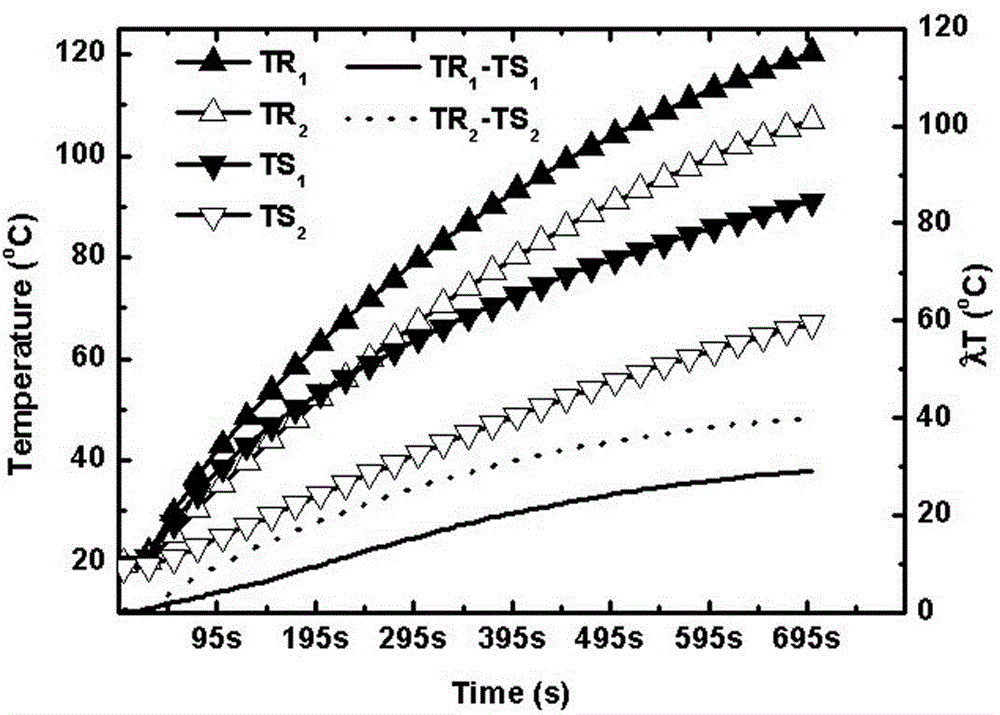

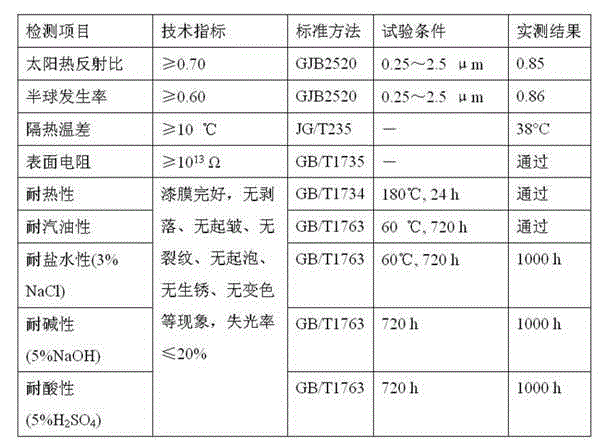

[0080] Example 1, this environment-friendly anti-corrosion and cooling integrated coating for storage tanks is composed of anti-corrosion primer, heat-insulating intermediate coating and cooling surface coating.

[0081] The raw material composition of described anticorrosion primer is as follows by weight ratio:

[0082] Acrylic emulsion 30 parts;

[0083] 28 parts of water;

[0084] 6 parts of iron titanium powder;

[0085] 5 parts of calcium carbonate powder;

[0086] 5 parts of precipitated barium sulfate powder;

[0087] 11 parts of talcum powder;

[0088] 0.7 parts of anti-flash rust agent;

[0089] 0.7 parts of anti-settling agent;

[0090] 1 part of dispersant;

[0091] Wetting agent 0.4 parts;

[0092] 0.4 part of defoamer;

[0093] Thickening and leveling agent 0.4 parts;

[0094] 0.4 part of film-forming aid;

[0095] The raw material composition of the heat-insulating intermediate layer coating is as follows in parts by weight:

[0096] Acrylic emulsion...

Embodiment 2

[0117] Example 2, this environment-friendly anti-corrosion and cooling integrated coating for storage tanks is composed of anti-corrosion primer, heat-insulating intermediate coating and cooling surface coating.

[0118] The raw material composition of described anticorrosion primer is as follows by weight ratio:

[0119] Acrylic emulsion 25 parts;

[0120] 25 parts of water;

[0121] 5 parts of iron titanium powder;

[0122] 3 parts calcium carbonate powder;

[0123] 4 parts of precipitated barium sulfate powder;

[0124] 10 parts of talcum powder;

[0125] 0.4 parts of anti-flash rust agent;

[0126] 0.5 parts of anti-settling agent;

[0127] 1 part of dispersant;

[0128] Wetting agent 0.2 parts;

[0129] 0.2 part of defoamer;

[0130] Thickening and leveling agent 0.2 parts;

[0131] 0.2 part of film-forming aid;

[0132] The raw material composition of the heat-insulating intermediate layer coating is as follows in parts by weight:

[0133] Acrylic emulsion 60...

Embodiment 3

[0154] Embodiment 3, this environment-friendly anti-corrosion and cooling integrated coating for storage tanks is composed of anti-corrosion primer, heat-insulating intermediate coating and cooling surface coating.

[0155] The raw material composition of described anticorrosion primer is as follows by weight ratio:

[0156] Acrylic emulsion 35 parts;

[0157] 32 parts of water;

[0158] 8 parts of iron titanium powder;

[0159] 7 parts of calcium carbonate powder;

[0160] 6 parts of precipitated barium sulfate powder;

[0161] Talcum powder 12 parts;

[0162] Anti-flash rust agent 1.2 parts;

[0163] 0.8 parts of anti-settling agent;

[0164] 2 parts of dispersant;

[0165] Wetting agent 0.6 parts;

[0166] 0.6 part of defoamer;

[0167] Thickening and leveling agent 0.6 parts;

[0168] 0.6 part of film-forming aid;

[0169] The raw material composition of the heat-insulating intermediate layer coating is as follows in parts by weight:

[0170] 80 parts of acryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com